2025 Top 10 Trends in CNC Manufacturing Revolutionizing the Industry

As we approach 2025, the landscape of CNC manufacturing is undergoing transformative changes that are set to revolutionize the industry. According to a report by Market Research Future, the global CNC machining market is expected to reach approximately $100 billion by 2025, driven by the increasing demand for precision engineering and automation across various sectors. This surge is not only indicative of the growing reliance on CNC technology in manufacturing processes but also highlights the critical role of advancements in methodologies and materials.

In this rapidly evolving environment, ten key trends are emerging that promise to redefine how CNC manufacturing operates. This includes advancements in artificial intelligence and machine learning that enhance operational efficiency and decision-making, as well as the integration of IoT technologies that facilitate real-time monitoring and predictive maintenance. Additionally, the emphasis on sustainability and eco-friendly practices is guiding manufacturers to innovate while minimizing their environmental impact. By examining these trends, we can gain insights into how CNC manufacturing will adapt to meet the challenges of the future and remain at the forefront of industrial innovation.

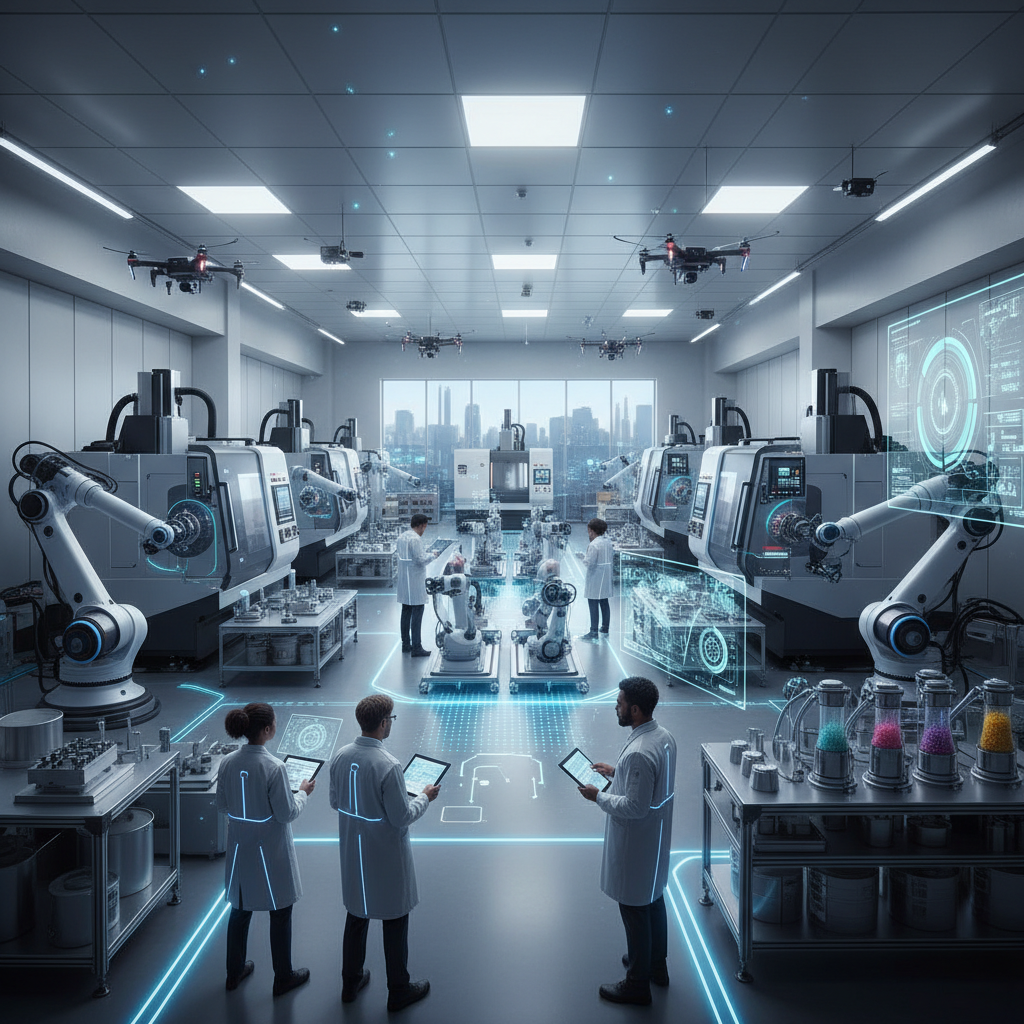

Emerging Technologies Enhancing CNC Machining Efficiency in 2025

The CNC manufacturing landscape is undergoing a significant transformation in 2025, driven by emerging technologies that enhance machining efficiency and productivity. A notable trend is the integration of artificial intelligence (AI) into CNC machine tools, which is projected to boost the market growth by USD 21.9 billion from 2025 to 2029. AI is enabling smarter machining processes, allowing for real-time data analysis and adaptive control, which minimizes waste and enhances precision.

In addition to AI, the trend of multi-axis machining centers is gaining momentum as manufacturers seek high-precision capabilities. The global CNC machine tools market is expanding rapidly, supported by the rising demand for these advanced systems. Reports indicate that the vertical machining centers are expected to grow at a CAGR of 7.8%, while horizontal machining centers will follow closely at 7.5%. Such advancements not only promise to improve the quality of components but also optimize production timelines, setting the stage for a remarkable evolution in CNC machining practices throughout various industries.

Integration of AI and Machine Learning in CNC Manufacturing Processes

The integration of AI and machine learning in CNC manufacturing processes is set to reshape the industry dramatically. As we advance towards 2025, machine learning technologies are becoming central to optimizing workflows, improving productivity, and enabling real-time decision-making. This transformation not only enhances efficiency in design and production but also minimizes human error, allowing for precise operations in complex manufacturing environments.

Tips for integrating AI: Start by assessing your current CNC processes and identifying areas where machine learning algorithms can be effectively applied. Consider investing in training for your team on new digital tools to ensure a smoother transition. Additionally, explore partnerships with technology providers that specialize in AI-driven solutions tailored for CNC applications to maximize the potential of your manufacturing operations.

As AI continues to advance, the incorporation of predictive analytics will become a game-changer in CNC manufacturing. This technology can anticipate maintenance needs and optimize scheduling, thus reducing downtime and improving overall equipment effectiveness. Commitment to embracing these innovations is crucial for staying competitive in the rapidly evolving manufacturing landscape.

2025 Top 10 Trends in CNC Manufacturing Revolutionizing the Industry - Integration of AI and Machine Learning in CNC Manufacturing Processes

| Trend Number | Trend Description | Impact on CNC Manufacturing | Implementation Timeline |

|---|---|---|---|

| 1 | Predictive Maintenance | Reduces downtime and maintenance costs by forecasting equipment failures. | 2023-2025 |

| 2 | Smart Factories | Enhances operational efficiencies through interconnected machinery and systems. | 2024-2026 |

| 3 | AI-Driven Design Optimization | Improves part design efficiency, reducing production time and costs. | 2025 |

| 4 | Advanced Robotics Integration | Increases production capacity and precision in manufacturing processes. | 2024-2027 |

| 5 | Integrated Quality Monitoring | Enhances quality assurance through real-time monitoring and adjustments. | 2023-2025 |

| 6 | Remote Monitoring and Control | Allows operators to manage CNC machines from anywhere, enhancing flexibility. | 2023-2025 |

| 7 | Customizable Production Platforms | Facilitates tailored production processes to meet unique customer needs. | 2025 |

| 8 | Sustainability Practices | Reduces waste and energy consumption through efficient manufacturing methods. | 2024-2025 |

| 9 | Digital Twin Technology | Creates a virtual replica of manufacturing processes for simulation and analysis. | 2025 |

| 10 | Collaborative Filter Algorithms | Enhances data analysis efficiency through machine learning models. | 2023-2025 |

Sustainable Practices Transforming CNC Production and Reducing Waste

The CNC manufacturing industry is witnessing a significant shift towards sustainable practices, which are not only transforming production methods but also reducing waste and increasing efficiency. According to a report by the International Federation of Robotics, approximately 71% of manufacturers are making strides to implement eco-friendly technologies in their operations. This movement is largely driven by the need to minimize environmental impact and comply with increasingly strict regulations.

Innovative strategies, such as the adoption of energy-efficient CNC machines, have proven effective in reducing energy consumption by up to 30%. Additionally, the integration of advanced recycling methods allows for the repurposing of scrap materials, significantly decreasing waste generation. A study from the National Institute of Standards and Technology revealed that companies implementing sustainable practices can achieve a cost reduction of about 15% in operational expenses over time, underlining the dual benefits of sustainability and profitability in modern CNC manufacturing. As these practices gain traction, they are not only revolutionizing production efficiency but are also setting a new standard for responsibility within the industry.

2025 Top 10 Trends in CNC Manufacturing

The Rise of Advanced Materials Shaping Future CNC Applications

The rise of advanced materials is fundamentally transforming CNC manufacturing. With the global CNC machine market set to experience significant growth—from $101.22 billion in 2025 to $195.59 billion by 2032—innovations in materials play a crucial role. Advanced composites, such as metamaterials, offer unique electromagnetic properties that are reshaping product design and functionality. These materials enable manufacturers to create lighter, stronger components that can enhance efficiency and performance across various applications.

Tips for embracing advanced materials in CNC manufacturing include investing in research and development to explore the potential of nanotechnology and other cutting-edge composites. Collaboration with universities and research institutions can foster innovation and ensure companies stay at the forefront of material science. Additionally, training staff on the capabilities and applications of new materials is essential for maximizing their benefits in production processes.

Furthermore, staying informed about global trends in manufacturing can help companies adapt and leverage advancements effectively. As industries evolve, companies that proactively integrate these advanced materials will likely gain a competitive advantage, ensuring they meet the demands of future applications while optimizing their operations.

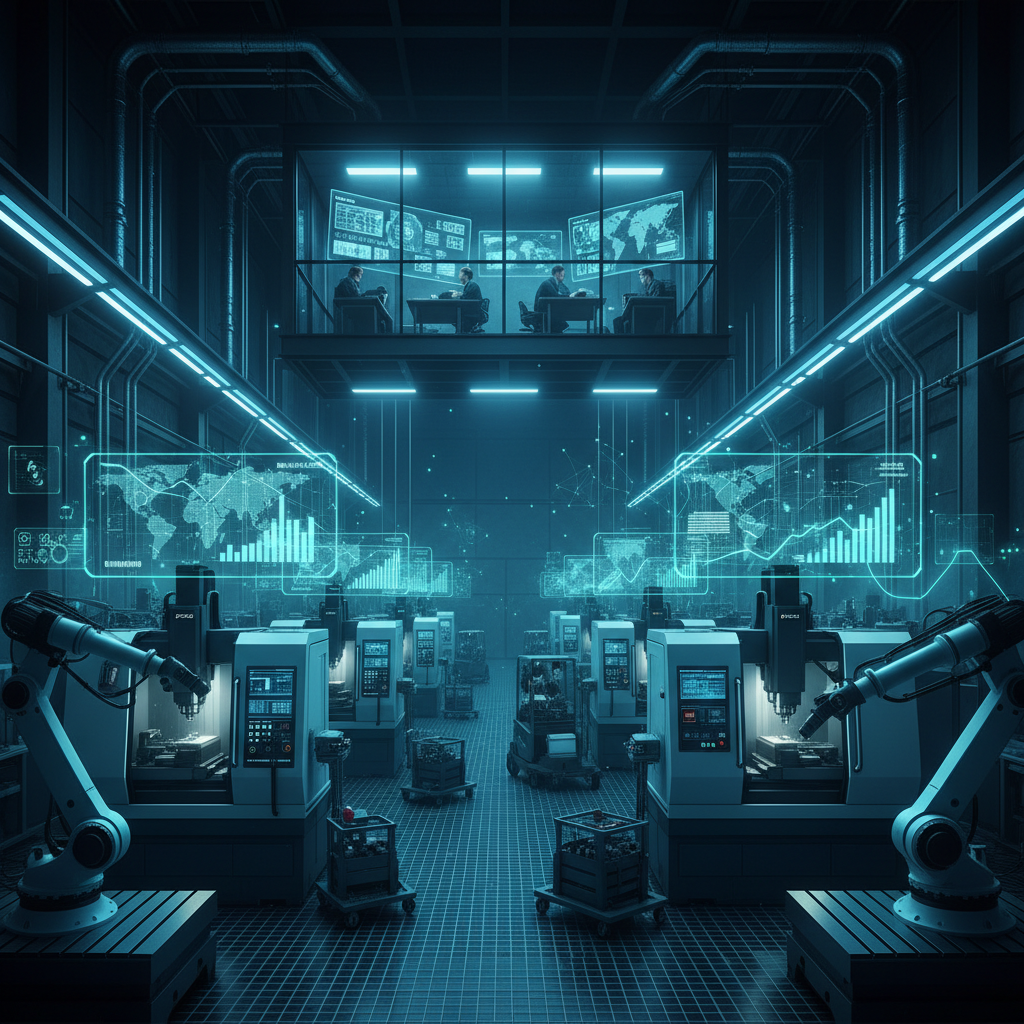

Smart Factories: The Role of IoT in Modern CNC Manufacturing Systems

The integration of the Internet of Things (IoT) in CNC manufacturing is transforming the landscape of smart factories, enabling unprecedented levels of efficiency and productivity. According to a report by MarketsandMarkets, the global IoT in manufacturing market is projected to reach $150.6 billion by 2025, reflecting a compound annual growth rate (CAGR) of 25.8% from 2020 to 2025. This rapid growth underscores the importance of IoT technologies in revolutionizing traditional CNC operations.

With IoT-enabled devices, manufacturers can gather real-time data from their machines, allowing for enhanced monitoring and predictive maintenance. Research from McKinsey indicates that companies implementing IoT solutions can reduce operational costs by up to 20% while increasing machine utilization rates by 10 to 20%. This shift not only optimizes performance but also fosters a data-driven approach to decision-making, ultimately driving innovation within smart factories.

As CNC manufacturing continues to evolve, the role of IoT will be crucial in creating a more interconnected and intelligent manufacturing ecosystem.

Related Posts

-

Ultimate Guide to Mastering CNC Turning Techniques for Precision Engineering

-

10 Essential Tips for Optimizing Your CNC Metal Cutting Process

-

How to Choose the Best CNC Metal Cutting Techniques for Your Manufacturing Needs

-

Understanding the Innovations Behind CNC Metal Cutting Techniques

-

How to Optimize CNC Parts Production with Advanced Machining Techniques and Precision Data

-

What is the Process Behind CNC Metal Cutting Technology