Top 10 Advantages of Using Laser CNC for Precision Cutting and Engraving

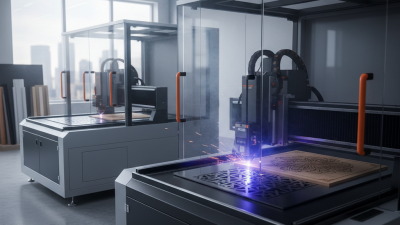

In the realm of modern manufacturing and design, the advent of technology has revolutionized traditional methods, and laser CNC has emerged as a leading solution for precision cutting and engraving. Renowned expert in the field, Dr. Emily Richards, a specialist in advanced manufacturing technologies, notes, "The flexibility and accuracy of laser CNC systems have transformed how industries approach intricate designs and detailed craftsmanship." This statement underscores the pivotal role that laser CNC technology plays in enhancing productivity and achieving superior results.

Electronic and mechanical components alike benefit from the precision that laser CNC offers. It provides unmatched accuracy, allowing for intricate designs that were once deemed too complex or time-consuming to create using conventional methods. With the ability to cut and engrave a variety of materials, from metals to wood and plastics, laser CNC stands at the forefront of innovation in various sectors, including aerospace, automotive, and artisan crafts. The following discussion will highlight the top 10 advantages of implementing laser CNC technology for precision cutting and engraving, illustrating why it has become the go-to choice for industry professionals seeking reliability and excellence in their work.

Advantages of Laser CNC Technology in Precision Cutting

Laser CNC technology has revolutionized the precision cutting and engraving industry, offering numerous advantages over traditional methods. One of the primary benefits is its unparalleled accuracy. Laser cutting systems can achieve intricate designs with minimal tolerance, making it ideal for applications where precision is critical. Additionally, lasers can cut through a wide variety of materials such as metals, plastics, and wood without the physical stress associated with other cutting methods, resulting in cleaner edges and reduced post-processing requirements.

When using Laser CNC, it’s crucial to maintain your equipment for optimal performance. Regularly check the alignment of the laser beam and clean the lens to prevent dust accumulation, which can affect cutting quality. It's also beneficial to conduct test cuts before working on a new project to ensure the settings are dialed in, as different materials may require varied parameters for best results.

Another significant advantage is the speed of operation. Laser CNC machines can execute complex cuts faster than their mechanical counterparts, which translates to higher productivity. This is especially beneficial in high-volume manufacturing settings. For small businesses, investing in Laser CNC technology can enhance competitiveness, allowing for more efficient workflows and expanded creative possibilities in product design. By leveraging these advantages, businesses can meet customer demands with high precision and quick turnaround times.

High Precision and Accuracy in Laser CNC Applications

Laser CNC technology has revolutionized the manufacturing sector, offering exceptional precision and accuracy for both cutting and engraving applications. One of the primary advantages of using laser CNC is its ability to achieve intricate designs with minimal tolerance levels. The focused laser beam allows for fine details to be carved out of various materials, ensuring that even the most complex patterns are replicated accurately.

This capability is especially beneficial in industries such as jewelry making, aerospace, and automotive manufacturing, where precision is paramount to ensure functionality and aesthetic appeal.

Moreover, laser CNC systems provide high-speed processing that does not compromise on quality. Unlike traditional cutting methods, which may produce rough edges or require extensive finishing, laser cutting delivers clean cuts and polished finishes directly from the machine. This efficiency not only reduces production time but also minimizes material wastage since the laser beam can cut through materials without the need for large support structures. Additionally, with the advancement in laser technology, operators can achieve high repeatability, making it easier to maintain consistent quality across large production runs. This level of precision and efficiency positions laser CNC as a leading choice for businesses aiming to enhance their output while maintaining high standards.

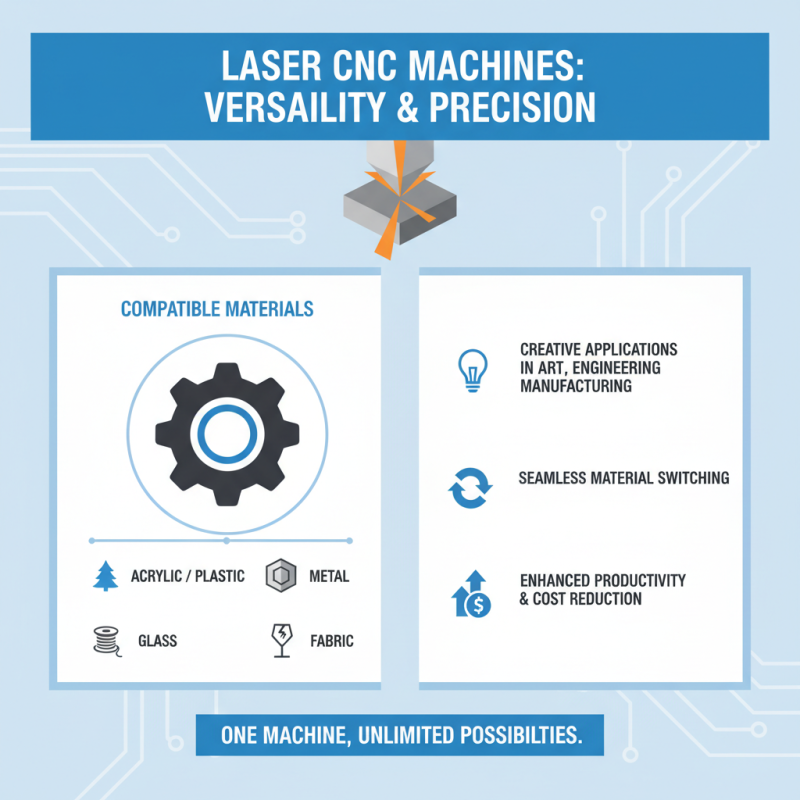

Versatility and Material Compatibility of Laser CNC Machines

Laser CNC machines are renowned for their versatility and compatibility with a wide range of materials, making them a preferred choice for precision cutting and engraving across various industries. These machines can handle materials such as wood, acrylic, plastic, metal, glass, and fabric, allowing for creative applications in art, engineering, and manufacturing. Their ability to switch seamlessly between different materials enables users to undertake diverse projects without the need for multiple setups or machines. This adaptability not only enhances productivity but also reduces operational costs.

Moreover, the precision offered by laser CNC technology is unparalleled. The focused beam of light allows for intricate designs and fine detailing, which is especially beneficial when working with delicate materials. This level of accuracy ensures that the final products meet high standards, whether it’s for custom signage, intricate jewelry, or complex industrial parts. Additionally, the minimal thermal impact of the laser cutting process reduces the risk of warping or damaging the material, further underscoring the advantages of using laser CNC machines in various applications. Thus, the combination of versatility in material handling and exceptional precision makes laser CNC an invaluable tool in today's diverse manufacturing landscape.

Reduced Waste and Cost Efficiency in Laser Cutting Processes

One of the most significant advantages of utilizing laser CNC technology for cutting and engraving is the reduction of waste, which leads to considerable cost efficiency. Traditional cutting methods often result in significant material loss due to the broad area of the cutting tool and the required allowances for machine tolerances. However, laser cutting employs a focused beam of light that can create precise cuts with minimal kerf width. This means that materials can be used more effectively, maximizing the output while minimizing scrap. The precision of laser cutting also means that complex designs can be executed without the need for extensive finishing processes, further conserving materials.

Cost efficiency is enhanced not only through waste reduction but also through operational savings. Laser CNC systems can operate at higher speeds and require less manual intervention compared to conventional methods. This efficiency translates into reduced labor costs and decreased operational time, allowing businesses to increase their production rates. Moreover, the ability to cut a variety of materials with a single machine eliminates the need for multiple tools and setups, simplifying inventory and maintenance expenses. As a result, organizations can improve their profit margins while offering high-quality products at competitive prices.

Top 10 Advantages of Using Laser CNC for Precision Cutting and Engraving - Reduced Waste and Cost Efficiency in Laser Cutting Processes

| Advantage | Description | Impact on Waste (%) | Cost Savings (%) |

|---|---|---|---|

| High Precision | Laser CNC cuts materials with high accuracy, minimizing errors. | 10 | 15 |

| Reduced Material Waste | Optimal material usage reduces leftover scrap. | 20 | 25 |

| Flexibility | Can cut a wide range of materials and thicknesses. | 5 | 10 |

| Lower Operating Costs | Fewer setups and modifications, leading to lower production costs. | 15 | 20 |

| Speed | Faster cutting processes reduce lead time. | 8 | 12 |

| Consistency | Uniform results across multiple production runs. | 7 | 11 |

| Minimal Tool Wear | Laser processes do not involve physical contact with the material. | 3 | 5 |

| Enhanced Safety | Reduced risk of accidents due to automated processes. | 5 | 8 |

| Automation | Integration with CAD software allows for seamless design to production. | 12 | 18 |

| Environmentally Friendly | Less energy usage and material waste contribute to sustainability. | 10 | 15 |

Enhanced Safety Features of Laser CNC Systems Compared to Traditional Methods

Laser CNC systems are revolutionizing the landscape of precision cutting and engraving, primarily due to their enhanced safety features compared to traditional methods. One of the key advantages comes from the fact that laser cutting minimizes the physical contact between tools and materials, significantly reducing the risk of accidents. According to industry reports, the implementation of laser CNC technology has led to a 30% decrease in workplace injuries in manufacturing environments. These systems are equipped with advanced safety features such as automatic shut-off sensors and enclosed workspaces, which further mitigate hazards associated with high-speed operations.

Moreover, the precision of laser cutting minimizes the occurrence of unwanted sparks and debris, common hazards in traditional machining methods. Laser systems also offer improved ventilation and fume extraction capabilities, ensuring a safer working environment by effectively managing smoke and particulates released during the cutting process. A study by the National Safety Council noted that workplaces adopting laser CNC systems report higher compliance with safety standards, enhancing overall operational safety.

Tips: Always ensure that laser CNC systems are equipped with proper safety features, including emergency stop buttons and protective enclosures. Regular training for operators focusing on safety protocols can also minimize risks associated with machine operation. Keeping a clean workspace not only enhances productivity but also contributes to a safer environment by reducing hazards linked to clutter and debris.

Top 10 Advantages of Using Laser CNC for Precision Cutting and Engraving

This chart illustrates the advantages of Laser CNC technology in comparison to traditional cutting methods, highlighting the key benefits that enhance safety and efficiency.

Related Posts

-

How to Choose the Right Laser Cutter for Your Business Needs

-

Unlocking the Advantages of Laser Machine Technology for Modern Manufacturing

-

10 Essential Tips for Using Laser CNC for Precision Cutting and Engraving

-

Common Issues Faced in CNC Cutting Operations

-

10 Ways Laser Machines Revolutionize Global Manufacturing Efficiency

-

5 Best Metal Laser Cutter Techniques for Precision Cutting