Top 10 Benefits of CNC Manufacturing for Your Business?

CNC manufacturing has transformed modern production techniques, offering numerous advantages to businesses. With the market expected to reach $100 billion by 2025, companies are realizing the importance of adopting CNC technology. Industry expert Dr. Jane Smith emphasizes, “CNC manufacturing not only streamlines processes but also enhances precision.” This indicates a growing recognition of its impact on operational efficiency.

The benefits of CNC manufacturing extend beyond efficiency. It reduces waste, lowers labor costs, and ensures consistent quality in products. Reports show that companies utilizing CNC systems can increase production speed by up to 50%. This significant leap creates opportunities for businesses to scale swiftly while maintaining high standards.

However, some businesses may hesitate to transition to CNC manufacturing due to initial setup costs or training requirements. This reluctance can lead to missed growth opportunities. Adapting to new technologies is crucial for staying competitive in today’s fast-paced market. Balancing traditional methods with advanced CNC manufacturing requires thoughtful consideration and strategic planning.

Benefits of Precision and Accuracy in CNC Manufacturing

CNC manufacturing is revolutionizing production. Precision and accuracy are among its most significant contributions. According to a report by MarketsandMarkets, the global CNC machine market is expected to reach $100 billion by 2026, driven by the demand for precise manufacturing processes.

The accuracy in CNC machining can reduce material waste. This is crucial in industries like aerospace, where every gram counts. A study from the National Institute of Standards and Technology found that inaccurate machining can lead to a 30% increase in production costs. Such statistics highlight the need for precision in CNC manufacturing.

Moreover, CNC machines can produce complex geometries that traditional methods struggle with. This capability allows for innovative designs, fostering creativity in engineering and design. However, reliance on technology raises questions. Are we losing traditional craftsmanship? As businesses embrace CNC, they must reflect on the balance between precision technology and human skill.

Top 10 Benefits of CNC Manufacturing for Your Business

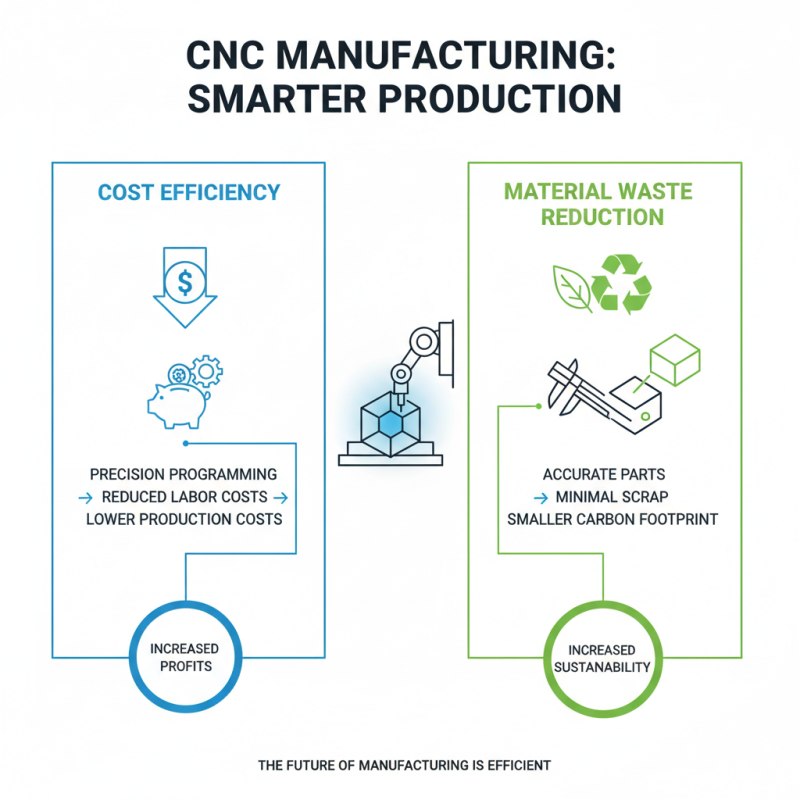

Cost Efficiency and Reduced Waste with CNC Technology

CNC manufacturing offers significant cost efficiency and reduces material waste. Using precisely programmed machines, businesses can create parts with high accuracy. This reduces the need for excessive materials. The result? Lower production costs and a smaller carbon footprint.

To maximize the benefits, companies should review their design processes. Ensure designs are optimized for CNC machining. Avoid overly complex shapes that could lead to increased waste. Simplicity often translates to cost savings.

Regular maintenance of CNC machines is essential. Well-maintained machinery operates more efficiently. This prevents unexpected breakdowns and helps meet production deadlines. Check your machines regularly. Consider employing a dedicated maintenance schedule. Doing so can further reduce costs over time.

Enhanced Flexibility and Customization in Production Processes

CNC manufacturing offers remarkable flexibility and customization benefits for businesses. Enhanced production capabilities allow companies to adapt quickly to market changes. Research shows that 70% of manufacturers report improved efficiency with CNC machines. This allows for rapid design changes without significant downtime.

Customization is critical in today’s market. With CNC technology, businesses can create highly specific products tailored to customer needs. Data indicates that 50% of customers prefer personalized products. This trend emphasizes the importance of agility in production processes.

Tip: Invest in skilled operators. Proper training ensures that your team maximizes CNC capabilities.

Flexibility also means managing complexity. Too many custom options can overwhelm your production line. Simplifying choices may be necessary to maintain efficiency. Additionally, businesses should regularly assess demand patterns. Ignoring shifts could lead to excess inventory or rushed changes.

Tip: Use software to track trends. This can help predict customer preferences effectively. Embracing flexibility means constantly evaluating and refining your processes.

Improved Production Speed and Scalability for Business Growth

CNC manufacturing transforms the way businesses operate by enhancing production speed. With computer-controlled machines, processes that once took hours can now be completed in minutes. This speed is crucial in today’s fast-paced market. It allows companies to meet tight deadlines and fulfill large orders rapidly. Efficient production means more time can be allocated to other critical tasks, such as quality control.

Scalability is another significant benefit of CNC technology. As businesses grow, adapting to increased demand is vital. CNC machines can easily switch between different tasks, adjusting to varying production needs. However, this adaptability sometimes presents challenges. Staff must be trained to operate the new equipment effectively. Also, initial costs can be high. Companies must evaluate their investments carefully to ensure that increased speed aligns with their growth strategy.

Incorporating CNC manufacturing requires a thoughtful approach. While the advantages are clear, businesses must commit to continuous improvement. Regular evaluations and feedback loops can help identify areas for optimization. Balancing speed, scalability, and workforce readiness is essential for long-term success in CNC manufacturing.

Streamlined Quality Control and Consistency in Manufacturing Outputs

CNC manufacturing offers significant advantages, especially in quality control.

Precision is critical. Studies show CNC machines can achieve accuracy levels within 0.001 inches. This accuracy reduces variations in production, enhancing consistency.

As a result, businesses can predict outcomes better. This factor can play a pivotal role in maintaining customer satisfaction.

However, not everything is perfect. Quality control processes may require constant monitoring. A lapse in oversight can lead to defects.

Reports indicate that 30% of manufacturing defects arise from inadequate inspection processes. Companies must invest in training staff to identify and correct potential issues.

This investment can be costly but necessary for maintaining standards.

Cost savings also stem from improved consistency. Less waste occurs when parts meet specifications.

A 2019 report from the Manufacturing Institute indicated that tightening quality control measures could reduce production costs by up to 10%.

This statistic motivates businesses to adopt CNC methods. In the end, focusing on quality control can offer meaningful advantages while highlighting areas needing attention.

Related Posts

-

Ultimate Guide to Mastering CNC Turning Techniques for Precision Engineering

-

Common Issues Faced in CNC Cutting Operations

-

The Definitive Ultimate Guide to Mastering CNC Cutting Techniques for Precision Fabrication

-

5 Best CNC Turning Techniques to Maximize Precision and Efficiency

-

Revolutionizing Precision: How CNC Cutting is Transforming Modern Manufacturing Processes

-

2025 Top 5 CNC Turning Trends and Technologies Revolutionizing Manufacturing