2026 Best CNC Metal Cutting Techniques for Precision and Efficiency?

In the rapidly evolving world of manufacturing, CNC metal cutting techniques are vital for achieving precision and efficiency. According to Dr. Emily Carter, a leading expert in CNC metal cutting, "The future of manufacturing lies in our ability to refine and adapt our cutting methods." This statement underlines the importance of innovation in our industry.

As we approach 2026, various CNC techniques will shape the landscape of metal fabrication. Advanced technologies like laser cutting and waterjet cutting are gaining traction. However, many companies still struggle with their implementation. It raises questions about the readiness of businesses to adapt to these innovations.

Moreover, despite the advancements, some traditional methods remain prevalent. This mix of old and new poses challenges. It invites reflection on industry practices and how they can evolve. Embracing change while recognizing the value of established techniques could lead to progress in CNC metal cutting. Each step forward is both an opportunity and a learning experience.

2026 Trends in CNC Metal Cutting Techniques: Precision and Efficiency

In 2026, CNC metal cutting techniques are evolving, emphasizing both precision and efficiency. Recent industry reports indicate that around 70% of manufacturers are adopting advanced CNC technology. This shift is driven by the demand for high-quality outputs with less waste. Modern CNC machines can achieve tolerances of 0.005 mm, which is a notable improvement over previous standards.

However, challenges persist. Not all sectors have fully embraced these technologies. Smaller operations often struggle with the upfront costs and necessary expertise. Reports suggest that nearly 30% of firms still rely on outdated methods. This gap can hinder productivity and competitiveness in the long run.

Emerging trends, such as automation integration, are game-changers. Automation can reduce production time by up to 50%. Yet, there's a steep learning curve. Many operators still lack proper training, which affects efficiency. Investing in workforce development is crucial. It is not only about machines; skills are vital for maximizing CNC technology's potential.

Comparing Traditional versus Modern CNC Methods for Metal Cutting

When comparing traditional and modern CNC methods for metal cutting, it's essential to consider their strengths and weaknesses. Traditional methods, like milling and turning, rely heavily on manual operation. These techniques can be less efficient, as they often involve longer setup times. However, they allow for a more hands-on approach. Precision is achievable, but it varies significantly with operator skill.

On the other hand, modern CNC techniques incorporate advanced technology. Automated systems enable faster production rates. Machines can execute complex designs with high accuracy, minimizing errors. But not all operators are familiar with this tech. Training is necessary, and without it, mistakes can happen. Additionally, there’s a risk of technical issues that can halt production.

Despite technological benefits, a balance is crucial. Manufacturers must assess their specific needs and the potential for errors in both systems. Old meets new, sometimes in unexpected ways. Understanding this balance can lead others to make informed choices that enhance efficiency and precision in metal cutting.

2026 Best CNC Metal Cutting Techniques for Precision and Efficiency

| Technique | Type | Precision (μm) | Material Compatibility | Typical Applications | Cycle Time (min) |

|---|---|---|---|---|---|

| Laser Cutting | Modern | 25 | Steel, Aluminum, Copper | Aerospace components, Automotive parts | 5 |

| Plasma Cutting | Modern | 50 | Steel, Stainless Steel, Aluminum | Heavy machinery, Construction | 10 |

| Waterjet Cutting | Modern | 20 | Metal, Glass, Stone | Art, Prototyping | 7 |

| Milling | Traditional | 50 | Aluminum, Brass, Steel | Machine components, Fixtures | 15 |

| Turning | Traditional | 30 | Steel, Aluminum | Shafts, Cylindrical parts | 12 |

Top CNC Technologies for Enhanced Metal Cutting Precision in 2026

In 2026, CNC metal cutting technology is evolving rapidly. Enhanced precision is crucial for industries demanding high-quality components. Advanced software algorithms are now optimizing cutting paths. This increases efficiency, but it also requires skilled operators. Balancing technology and human expertise presents ongoing challenges.

Laser cutting remains prevalent due to its accuracy. However, newer methods like plasma and waterjet cutting are gaining traction. These techniques allow for versatile applications. Each method has its strengths, yet they sometimes fall short in specific scenarios. Operators must choose wisely based on material types and thickness.

Automation is reshaping the landscape of CNC machining. Robots can perform repetitive tasks, freeing up human workers for complex operations. Yet, over-reliance on automation risks losing critical craftsmanship skills. Industry leaders must find a way to integrate human insight with automated processes. The pursuit of perfection in metal cutting is ongoing, filled with both progress and pitfalls.

Efficiency Metrics: Evaluating Cutting Speed and Material Utilization

Cutting speed is a pivotal factor in CNC metal machining. It directly influences the efficiency of the cutting process. According to a recent industry report, optimal cutting speeds can enhance productivity by 30%. However, choosing the wrong speed can lead to tool wear and decreased precision. It’s critical to find the right balance for each material type. For instance, aluminum requires different settings than stainless steel.

Material utilization is another critical metric. Efficient cutting minimizes waste. Reports indicate that reducing scrap material can improve overall profitability by up to 15%. Employing proper nesting techniques and advanced software can aid in this effort. Yet, many manufacturers overlook these methods. They may prioritize speed over efficiency, leading to unnecessary material loss. Continuous evaluation of these metrics is essential.

A focus on both cutting speed and material utilization will refine processes. However, optimization is an ongoing challenge. Sometimes, industry standards may not fit unique production needs. Companies must regularly assess their methods to find areas for improvement. Monitoring variances in cutting performance can reveal insight into needed adjustments. Balancing speed and material usage remains a complex, but vital aspect of CNC machining.

Future Innovations in CNC Cutting: Automation and AI Integration

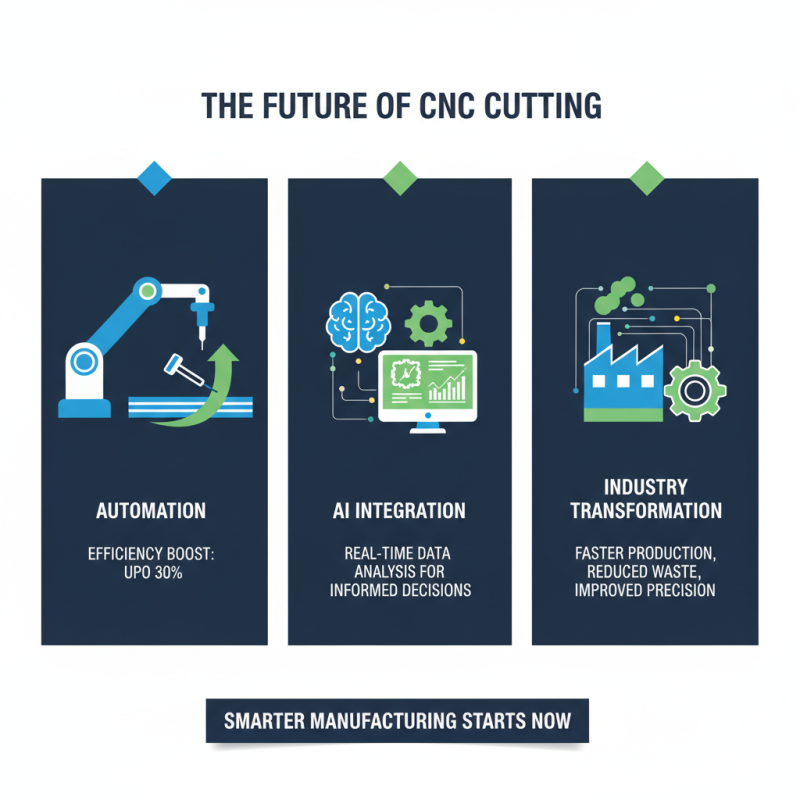

The integration of automation and AI in CNC cutting is transforming the industry. Reports indicate that automation could increase efficiency by up to 30% in the next few years. Companies are turning to AI for real-time data analysis. This helps in making informed decisions during production.

However, the technology is not without challenges. Many firms struggle with the initial costs and training required for such innovations. Moreover, there are concerns about job displacement. According to industry studies, 40% of workers fear that automation may replace their roles.

Implementation of AI brings both promise and complexity. Automated systems offer improved precision but may lack adaptability in unexpected scenarios. A balance must be struck between human oversight and machine learning. As companies navigate these transitions, the focus should be on developing systems that complement human skills rather than replace them.

Related Posts

-

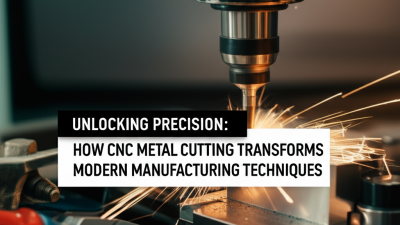

Unlocking Precision: How CNC Metal Cutting Transforms Modern Manufacturing Techniques

-

10 Essential Tips for Optimizing Your CNC Metal Cutting Process

-

Unlocking the Future: How CNC Manufacturing is Revolutionizing Modern Production Techniques

-

What Makes Metal CNC Machines Essential for Modern Manufacturing

-

What is the Process Behind CNC Metal Cutting Technology

-

Why CNC Metal Cutting is Essential for Modern Manufacturing Efficiency