2026 Best CNC Mill Options for Precision Machining and Efficiency?

When considering industrial machining, the choice of a CNC mill can be crucial. Precision and efficiency are paramount for manufacturers aiming for the best results. In 2026, the landscape of CNC mills is evolving rapidly, offering a range of options that cater to various needs.

Modern CNC mills come equipped with advanced features. They promise higher accuracy and faster production times. However, not all CNC mills are created equal. Some may excel in speed but lack precision. Others might achieve great precision while falling short in efficiency.

Identifying the best CNC mill involves evaluating specific requirements. For example, what types of materials will you be working with? Consider the space you have available as well. A comprehensive review of these elements can lead to a better decision. Each choice requires reflection and careful analysis, ensuring the selected CNC mill meets both current and future demands.

Overview of CNC Milling Machines in 2026

As CNC milling machines evolve, the landscape of precision machining is changing rapidly. In 2026, engineers and manufacturers are prioritizing versatility and efficiency. New models integrate advanced software for better control. These machines are getting smarter, but that also means they require skilled operators. Training is essential to maximize their potential.

The latest CNC mills offer features like faster setup times and improved accuracy. However, higher technology often comes at a cost. Operators may feel overwhelmed by constant updates and software changes. Some workers struggle to adapt to these advancements. A more user-friendly interface could alleviate some of these issues.

Moreover, sustainability is becoming a focal point. CNC milling machines must now also focus on reducing waste. Efficient energy use is not just a trend—it’s necessary for the future. Even with all these innovations, challenges remain. Balancing cost, efficiency, and skill training is crucial for success in the CNC milling space.

2026 CNC Mill Options: Precision and Efficiency Comparison

This chart compares three different CNC mill options available in 2026, focusing on essential performance metrics such as milling speed, feed rate, accuracy, maximum material thickness, and energy consumption. These dimensions help in evaluating the efficiency and precision of each milling machine.

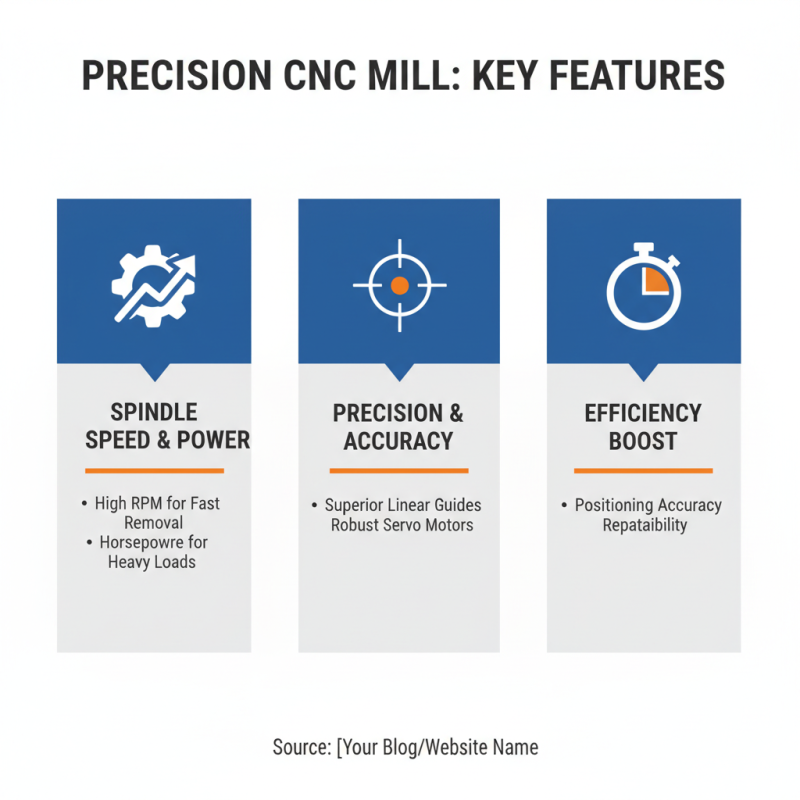

Key Features for Precision Machining

When choosing a CNC mill for precision machining, focus on key features that enhance efficiency. The spindle speed and power are crucial. High RPMs enable quick material removal. Adequate horsepower is essential to maintain performance under heavy loads. Precision is paramount, so look for mills with superior linear guides and robust servo motors. These components enhance positioning accuracy and repeatability.

Tips: Always assess the machine's rigidity. A stable machine settings lead to consistent results. Additionally, consider the control software. User-friendly interfaces can significantly reduce setup time. Sometimes, complex software can introduce errors.

Another vital feature is the tooling compatibility. Ensure the mill can accommodate various tool types for flexibility. Versatile tooling options allow for changes in project scope. Don't overlook the machine's footprint and weight. A heavy-duty mill often provides better stability but may limit workspace. Evaluate your shop’s capabilities before making a decision. Reflect on the balance between capability and space.

Top CNC Mill Brands and Models for Efficiency

When looking for CNC mills for precision machining, understanding the brands and models that excel in efficiency is crucial. Research shows that the CNC milling machine market is expected to grow significantly, reaching $4.6 billion by 2026. This growth highlights the need for users to identify machines that optimize their processes.

In terms of efficiency, factors such as spindle speed, feed rate, and tool geometry are essential. Machines with high spindle speeds can reduce machining time. A report from a reputable industry source indicates that increasing spindle speed by just 20% can lead to a 30% reduction in processing time. However, optimal performance requires a balance between these variables. Overshooting your spindle speed can lead to quality defects or tool wear.

Tip: Always assess your machining needs before purchasing. Choosing a model that fits your specific requirements can improve overall productivity.

It’s also vital to consider the technology in new models. Recent advancements include improvements in automation and software integration. Some users reported initial difficulties adapting to these technologies. However, the long-term benefits are worth the effort. It's essential to embrace these changes for improved efficiency in the long run.

Tip: Invest time in training. Understanding the full capabilities of advanced CNC mills can yield significant returns.

Comparative Analysis of CNC Mill Performance

When evaluating CNC mills, precision and efficiency are critical factors. Users often glance at specifications but overlook performance nuances. It's vital to consider factors like rigidity, weight distribution, and machining speed. Not all machines perform equally, even with similar specs. Some might vibrate too much, affecting the surface finish.

Comparing different models, we can observe variances in cutting capabilities. Some mills excel in aluminum machining, while others perform better with harder materials. It’s not just about the cutting tool; the machine's design plays a key role. Many users report that even minor setbacks, like tool chatter, can lead to poor outcomes. Not everyone tests their machines thoroughly before purchase.

Noise levels are another performance aspect often ignored. Some users may find the machines frustratingly loud. Additionally, maintenance can often feel overwhelming. Not all mills offer ease of access for routine checks. Users should be cautious about their long-term service needs. This can impact efficiency over time. Small details matter significantly in the CNC milling experience.

Future Trends in CNC Milling Technology

The future of CNC milling technology is undoubtedly exciting. Advancements are shaping how precision machining will evolve. Automation is becoming more prevalent in mills. Robots can handle complex tasks, reducing manual labor. This transformation allows for greater efficiency and precision in manufacturing processes.

Emerging trends also focus on integrating AI and machine learning. These technologies enhance decision-making capabilities in milling operations. By analyzing data in real time, they optimize cutting processes and reduce waste. However, implementing these technologies can be challenging. Companies must invest in training and infrastructure.

Another area of growth is sustainable milling practices. There is a push towards eco-friendly materials and processes. This shift may require changes in equipment and workflows. While the benefits are clear, the transition can be difficult. Manufacturers must balance efficiency with environmental responsibility. Adapting to these trends will require careful planning and reflection on existing practices.

Related Posts

-

Top 5 CNC Milling Machines of 2025: Unmatched Precision and Performance

-

How to Choose the Right CNC Milling Machine for Your Projects

-

Common Challenges Faced by Global Buyers When Choosing Metal CNC Machines

-

What Makes Metal CNC Machines Essential for Modern Manufacturing

-

What is the Process Behind CNC Metal Cutting Technology

-

10 Best CNC Metal Cutting Technologies That Boost Efficiency by 30 Percent