2026 Best Prototype Machining Techniques and Innovations?

In the rapidly evolving landscape of manufacturing, prototype machining plays a pivotal role. A recent report from the International Journal of Advanced Manufacturing Technology highlights that prototype machining can reduce development time by up to 30%. Innovations in this field are crucial for industries seeking to enhance production efficiency. As companies embrace advanced techniques, they find themselves navigating both opportunities and challenges.

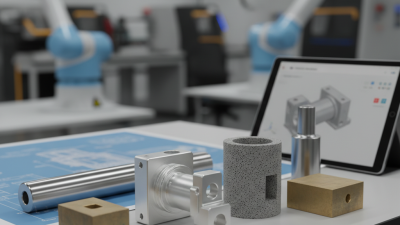

New technologies such as additive manufacturing and CNC machining have transformed traditional practices. Many businesses leverage these methods to produce intricate designs with greater precision. However, rapid advancements often lead to steep learning curves. Not all manufacturers adapt quickly to new machining techniques. This creates gaps that need addressing, with some companies struggling to optimize their processes.

The increasing demand for customized prototypes requires continuous innovation. According to a report by Statista, the global prototype machining market is projected to reach $5 billion by 2026. This growth reflects a growing need for specialized skills and technologies. As industries push boundaries, there is an urgent call to reflect on the effectiveness of current practices. The future of prototype machining depends on balancing innovation with skill development and process refinement.

Emerging Trends in Prototype Machining Techniques for 2026

In 2026, the landscape of prototype machining is shifting rapidly. Innovations in materials are paving the way for lighter and stronger prototypes. New alloys and composites enhance durability while reducing weight. These materials allow for more intricate designs, pushing the boundaries of what prototypes can achieve.

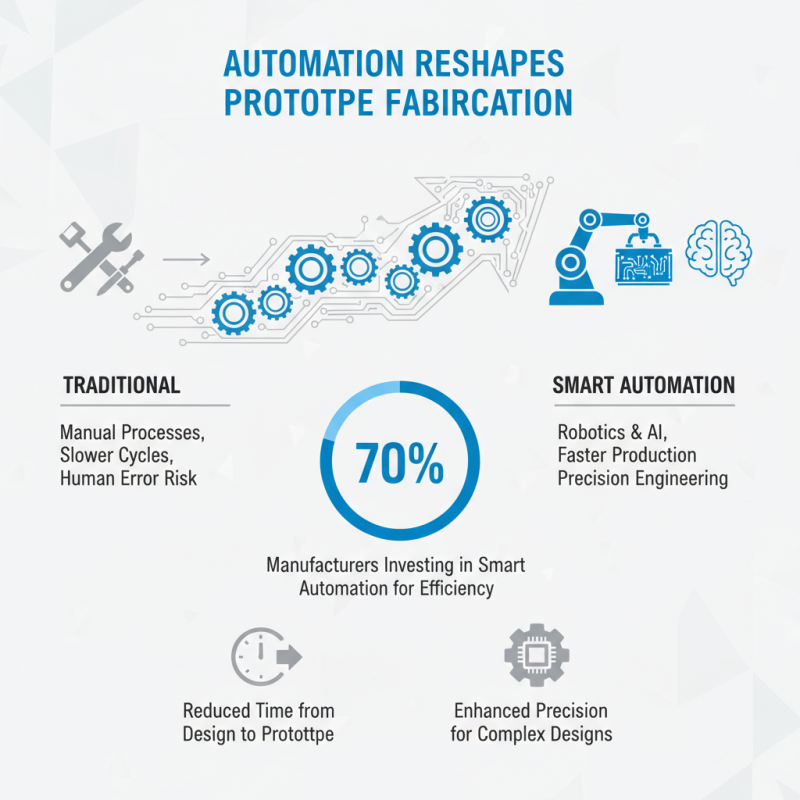

Automation is another emerging trend. Advanced robotics and AI are streamlining the machining process. They increase precision and reduce human error. However, reliance on technology may lead to skill gaps among workers. This raises questions about the future workforce in the machining sector.

Lastly, sustainability is gaining focus. Eco-friendly practices in prototype machining are becoming essential. Techniques that minimize waste and energy consumption are on the rise. Yet, balancing innovation and environmental responsibility presents challenges. Manufacturers must carefully consider their impact. The future of machining depends on these critical reflections and shifts.

2026 Best Prototype Machining Techniques and Innovations

| Technique | Description | Advantages | Applications |

|---|---|---|---|

| Additive Manufacturing | Layer-by-layer construction of parts using materials like plastics and metals. | Complex geometries, reduced waste, and rapid prototyping. | Aerospace, automotive, and medical devices. |

| CNC Machining | Computer-controlled cutting of materials for precision parts. | High accuracy, repeatability, and versatility. | Manufacturing, prototyping, and custom parts. |

| Micro machining | Precision machining of small components using specialized equipment. | High precision and surface finish for tiny parts. | Electronics, medical devices, and watchmaking. |

| Laser Cutting | Using laser technology to cut materials with high precision. | Smooth finishes, intricate designs, and minimal material loss. | Fabrication, signage, and artistic designs. |

| Hybrid Manufacturing | Combines additive and subtractive processes in one setup. | Increased efficiency and integration of complex features. | Tooling, aerospace, and custom parts. |

Innovative Materials and Tools in Modern Machining Processes

The machining industry is witnessing rapid advancements in materials and tools. Innovative materials like titanium alloys and advanced composites are transforming standards. According to a recent report, the use of titanium in machining processes has increased by 35% in the last five years. This surge highlights the material's strength-to-weight ratio, crucial for aerospace and automotive applications.

Modern tools are evolving alongside these materials. Cutting-edge tool coatings, such as diamond-like carbon, drastically enhance tool life. Some studies indicate that these coatings can improve durability by over 50%. However, the complexity of using such tools often leads to challenges. Machinists must adapt quickly to new technologies, which can lead to errors if not carefully managed.

Additive manufacturing is also making waves. Combining machining with 3D printing allows for intricate designs that were once impossible. Yet, this innovation is still in its infancy. Many in the industry struggle to integrate these technologies effectively into existing workflows. Despite these hurdles, the potential for increased efficiency and creativity is significant.

2026 Best Prototype Machining Techniques and Innovations

This chart showcases the effectiveness of various prototype machining techniques in 2026, highlighting their average productivity levels along with cutting-edge innovations.

Automation and Smart Technology in Prototype Fabrication

The rise of automation and smart technology is reshaping prototype fabrication. According to recent reports, 70% of manufacturers are investing in smart automation to improve efficiency. This shift allows for faster production cycles, reducing time from design to prototype. Robotics and AI are key players in this revolution. They enhance precision, enabling complex designs to be realized with minimal human intervention.

However, not all implementations are seamless. Many companies face challenges integrating these technologies. In a survey, 48% of firms noted difficulties in training staff to work with advanced machinery. Additionally, automated systems can create dependency, limiting creative input from engineers and designers. Balancing automation and human insight remains crucial. Achieving this balance requires continuous evaluation of technology’s role in creative processes.

Data shows that smart technology improves defect rates, but not without concerns. Approximately 30% of prototypes produced with high automation faced issues requiring rework. This highlights the need for ongoing assessment. As businesses adopt these techniques, they must consider how to keep human creativity alive. Embracing both technology and human expertise may lead to the best outcomes in prototype machining.

Sustainable Practices in Prototype Machining: A 2026 Perspective

In 2026, sustainable practices in prototype machining are gaining traction. Many companies are shifting their focus to environmentally friendly techniques. The integration of renewable energy sources for powering machinery is becoming more prevalent. This change not only reduces carbon footprints but also cuts operational costs.

Tips: Consider assessing your energy sources regularly. Look for ways to incorporate renewable options. Small changes can lead to significant benefits.

Moreover, the materials used in prototype machining are evolving. Companies are embracing biodegradable and recycled materials. This practice helps decrease waste and promotes sustainability. However, the challenge lies in balancing quality and eco-friendliness. Not every biodegradable material meets performance standards.

Tips: Test different materials before large-scale production. Choose options that align with both sustainability and your project's needs. Sometimes, compromise is necessary.

Case Studies: Successful Implementations of New Machining Innovations

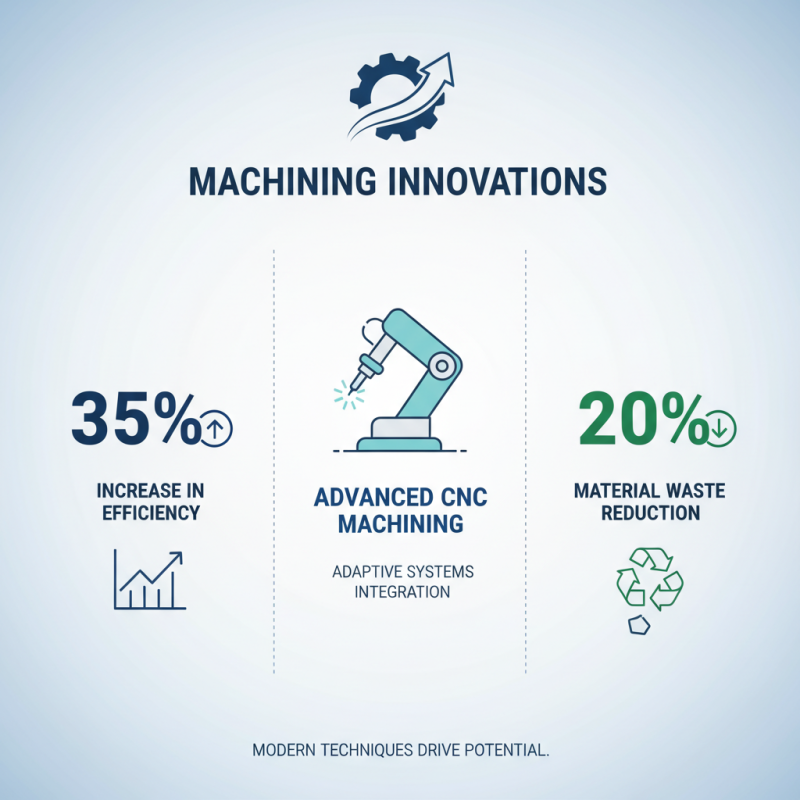

In recent years, the machining industry has seen remarkable innovations. One notable case study involved a company that implemented advanced CNC machining techniques. They reported a 35% increase in efficiency. By integrating adaptive machining systems, they reduced material waste by approximately 20%. Such improvements highlight the potential of modern techniques.

Another example comes from a firm that adopted 3D printing in conjunction with traditional machining. This hybrid approach allowed for quicker production cycles. They achieved a 40% reduction in lead times and improved product accuracy. However, reliance on new technologies raised questions about workforce skill gaps. Additional training will be essential to fully leverage these advancements.

A report by industry analysts indicated that 58% of companies are exploring automation in their machining processes. Yet, many faced hurdles during implementation. Some machines simply could not integrate with existing setups. This underscores the need for careful planning and a willingness to adapt. The path forward is not without challenges. But the potential rewards make it worth pursuing.

Related Posts

-

5 Essential Tips for Optimizing Your Prototype Machining Process to Achieve 20% Faster Production Times

-

Essential Guide to Prototype Machining Techniques and Benefits

-

How to Choose the Right Metal CNC Machine for Your Project Needs

-

Top 5 CO2 Laser Cutters for Precision and Quality?

-

How to Achieve Precision with Aluminum Machining Techniques

-

How to Choose the Best CO2 Laser Cutter for Your Projects and Needs