Top 10 Best Sheet Metal Fabrication Techniques for Your Industry Needs

In the ever-evolving landscape of manufacturing, sheet metal fabrication has emerged as a pivotal technique across various industries, offering versatility and efficiency in production. According to a report by Markets and Markets, the global sheet metal fabrication market is projected to reach $266.02 billion by 2025, driven by the increasing demand for customized products and innovative designs. This growing trend underscores the importance of mastering various fabrication techniques to meet the specific needs of diverse sectors such as automotive, aerospace, and construction.

As industries become more competitive, the ability to choose the right sheet metal fabrication technique can significantly impact operational efficiency and product quality. Techniques such as laser cutting, bending, and welding are not merely processes, but essential strategies that influence the overall performance of fabricated products. The precision and adaptability of these methods play a crucial role in enhancing productivity and reducing waste, further contributing to the industry’s sustainability goals. Consequently, understanding and implementing the top sheet metal fabrication techniques is imperative for businesses aiming to thrive in a dynamic market environment.

Overview of Sheet Metal Fabrication Techniques

The sheet metal fabrication industry is witnessing significant growth, driven by advancements in manufacturing techniques and increasing demand across various sectors. The global sheet metal processing equipment market is projected to expand from $35.51 billion in 2025 to $61.78 billion by 2032, reflecting a robust compound annual growth rate (CAGR). This surge indicates a rising need for efficient and innovative fabrication methods tailored to diverse industrial requirements.

Moreover, the sheet metal fabrication services market is estimated to surpass approximately $33.31 billion by 2034, up from $22.32 billion in 2025. Such growth underscores the critical role of effective fabrication techniques in enhancing productivity and reducing waste in manufacturing processes. Innovations like zero-defect manufacturing, exemplified by initiatives such as the EU-funded FormPlanet project, are pivotal for the industry's evolution, aiming to streamline operations and boost quality in sheet metal products. The increasing investments in state-of-the-art technology are expected to further optimize fabricating techniques, positioning the sector for sustained development in the years to come.

Importance of Selecting the Right Fabrication Method

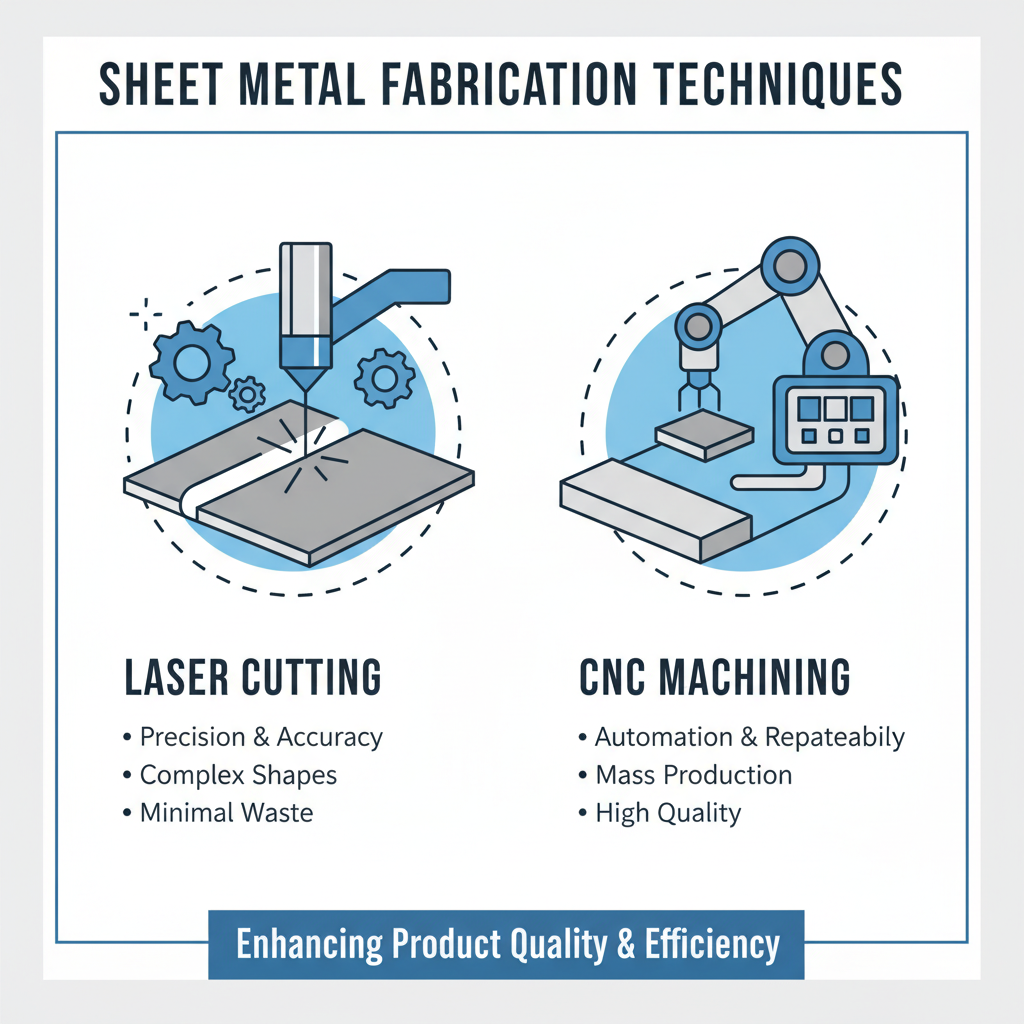

Selecting the right sheet metal fabrication method is crucial for meeting both quality and cost-effectiveness in your projects. Each technique—whether it be laser cutting, welding, or punching—offers distinct advantages and is tailored to specific industry needs. The appropriate choice can enhance the durability of the final product and ensure that it aligns with design specifications, ultimately leading to improved customer satisfaction.

Tips: When choosing a fabrication method, consider the material thickness and the complexity of the design. For intricate shapes, laser cutting might be the best fit due to its precision. Additionally, always factor in production volume; techniques like CNC machining might be more efficient for larger runs, while methods such as waterjet cutting could reduce waste for smaller projects.

Furthermore, keep in mind the lead time and budget constraints for your industry. Understanding the capabilities and limitations of various techniques can help streamline production. Engaging with experienced fabrication partners can also provide insights into innovative solutions that can meet unique demands, facilitating smoother project execution.

Top 10 Best Sheet Metal Fabrication Techniques

Common Applications of Sheet Metal in Various Industries

Sheet metal is an integral component in various industries, with applications spanning automotive, aerospace, construction, and electronics. In automotive manufacturing, sheet metal is essential for producing components such as body panels, chassis, and structural parts. These components require precision and strength, making advanced fabrication techniques crucial for meeting safety and regulatory standards.

Additionally, the aerospace sector relies heavily on lightweight and durable metal sheets to create fuselages, wings, and other critical components that ensure efficiency and performance in flight.

The construction industry also significantly utilizes sheet metal in the form of roofing, cladding, and ductwork. The growing demand for sustainable and energy-efficient buildings has resulted in a surge in the use of metal sheets due to their recyclability and durability. Furthermore, the electronics industry incorporates sheet metal in the production of enclosures and casings that safeguard sensitive components while allowing for effective heat dissipation. As these industries continue to evolve, the importance of advanced sheet metal fabrication techniques and services will only increase, driving innovations and market growth in the coming years.

Detailed Analysis of Top Fabrication Techniques

Sheet metal fabrication techniques are crucial for a variety of industries, offering precision and versatility in design. Among the top methods, laser cutting stands out for its accuracy and speed, allowing manufacturers to create complex shapes with minimal material waste. Another significant technique is CNC machining, which provides high levels of automation and repeatability, essential for mass production. These methods not only enhance product quality but also improve efficiency in the manufacturing processes.

**Tips:** When selecting a fabrication technique, consider your specific industry needs and the material properties required for your final product. Evaluate the initial investment against the long-term benefits of advanced methods like additive manufacturing, which can lead to significant cost savings and innovative designs. Staying updated on market trends, such as the growth forecast for the global semiconductor equipment manufacturing market, can also guide decision-making processes in adopting new fabrication technologies.

Future Trends in Sheet Metal Fabrication Technology

The future of sheet metal fabrication is poised for transformative advancements driven by emerging technologies and innovative practices. At events like FABTECH 2025, the spotlight is on groundbreaking welding technologies that promise to enhance productivity and precision in metalworking. Key trends include the integration of automation and robotics to streamline processes, which not only increases efficiency but also addresses the growing need for sustainable manufacturing practices. This shift towards automation is not just about optimizing workflows; it signifies a commitment to reducing errors and improving safety in the manufacturing environment.

Additionally, the rise of 3D printing technologies in sheet metal fabrication is reshaping the industry landscape. It offers unparalleled versatility, enabling manufacturers to produce complex parts with less waste and shorter lead times. As these technologies continue to evolve, they will play a critical role in enhancing supply-chain resilience, ultimately allowing companies to respond more effectively to market demands while minimizing their carbon footprints. This forward-looking approach is essential in an era where sustainability and agility are paramount to success in the competitive manufacturing sector.

Related Posts

-

Why CNC Metal Cutting is Essential for Modern Manufacturing Efficiency

-

Exploring the Future of Manufacturing with Advanced Laser Machine Technology

-

Common Issues Faced in CNC Cutting Operations

-

Revolutionizing Precision: How CNC Cutting is Transforming Modern Manufacturing Processes

-

Unlocking Precision: How CNC Metal Cutting Transforms Modern Manufacturing Techniques

-

2025 Top 5 CNC Turning Trends and Technologies Revolutionizing Manufacturing