Why Choose a Laser Machine for Your Business Needs?

Investing in a laser machine can be a game changer for many businesses. These machines offer precision and efficiency. They are designed to cut, engrave, and mark various materials. A laser machine can enhance product quality while reducing waste. Imagine being able to create intricate designs on wood, metal, or acrylic with ease.

However, the decision is not always straightforward. A laser machine requires careful consideration of costs, training, and maintenance. Some businesses may struggle to adapt to this technology. It’s important to assess your specific needs before jumping in. Not every application suits laser technology, and that’s worth thinking about.

When properly integrated, a laser machine can improve overall workflow. It empowers businesses to deliver unique products. The possibilities are vast, but so are the challenges. Balancing the benefits against potential hurdles is essential for making the right choice.

Benefits of Laser Machines for Precision Manufacturing in Various Industries

Laser machines are transforming precision manufacturing across various industries. According to a report by MarketsandMarkets, the laser cutting market is expected to reach $7.9 billion by 2026. This growth highlights the increasing importance of laser technology in manufacturing processes. Industries like automotive and aerospace rely on laser machines for their efficiency and precision.

Laser machines can easily cut through materials like metals and plastics. They produce less waste compared to traditional methods. This precision reduces costs and increases productivity. Despite their advantages, not all businesses fully utilize these machines. Some may underestimate their capabilities. Effective training is crucial to maximize their potential. Employees must understand operational intricacies.

The versatility of laser technology is remarkable. It can engrave, cut, and weld with high accuracy. A study found that laser systems improve manufacturing speed by up to 25%. However, not every company has adapted to this shift. Ignoring advancements may leave businesses behind in competitive markets. Embracing laser technology could unlock new opportunities and enhance product quality.

Why Choose a Laser Machine for Your Business Needs? - Benefits of Laser Machines for Precision Manufacturing in Various Industries

| Industry | Benefits | Applications | Precision Level |

|---|---|---|---|

| Manufacturing | High precision cutting | Metal parts fabrication | Micron accuracy |

| Textiles | Intricate designs | Custom clothing, patterns | High detail |

| Jewelry | Fine detailing | Engravings, custom pieces | High fidelity |

| Electronics | Minimized waste | Circuit board manufacturing | Nano precision |

| Automotive | Customization | Trim pieces, logos | High accuracy |

Cost Efficiency and Long-Term Savings of Laser Cutting Technologies

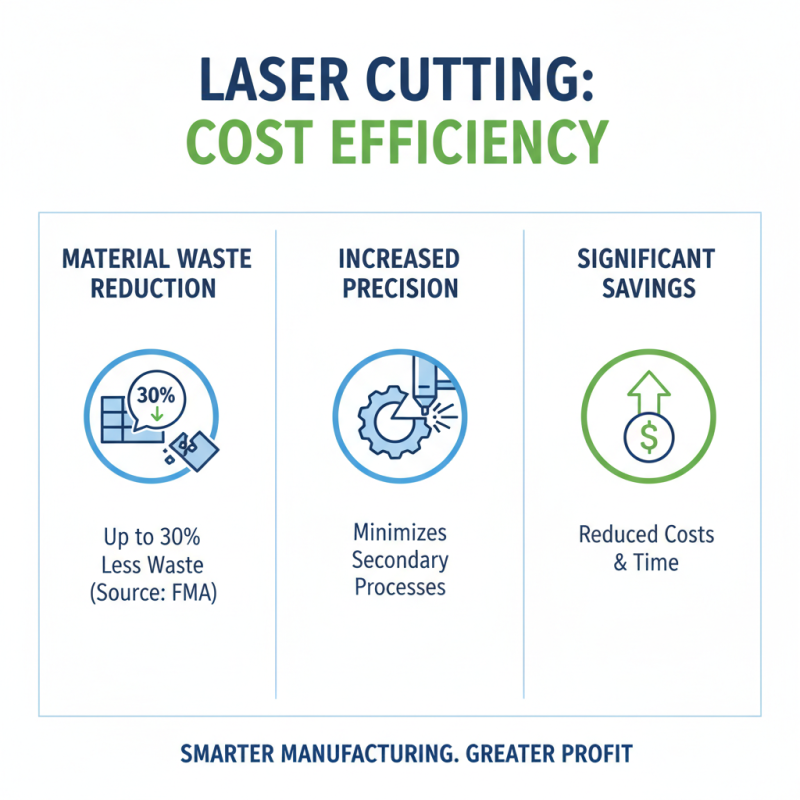

Laser cutting technologies have become a popular choice for businesses seeking cost efficiency. Research by the Fabricators & Manufacturers Association shows that laser machines can reduce materials waste by up to 30%. This reduction in waste directly translates to significant savings. Moreover, laser cutting offers precision. This precision minimizes the need for secondary processes, further cutting costs.

Replacing traditional cutting methods with laser technology brings operational savings too. According to a report by the International Laser Manufacturing Technology Association, companies can reduce production time by 20-40%. This speed allows businesses to meet demand swiftly. However, the initial investment in laser technology can be daunting. It's crucial to weigh that against long-term savings and productivity increases.

While lasers present clear financial advantages, they also come with challenges. Maintenance costs can be higher than anticipated. Operators must also undergo specialized training to wield this technology effectively. Balancing these factors is essential for any business contemplating a switch to laser cutting.

Comparative Analysis: Laser Machines vs. Traditional Cutting Methods

Laser machines offer precision and flexibility that traditional cutting methods struggle to match. According to a 2022 industry report, laser cutting can improve accuracy by up to 30% compared to mechanical cutting. The ability to cut intricate designs without the need for physical tooling reduces waste and increases material utilization. For businesses, this translates to lower operational costs and improved efficiency.

Traditional methods often face limitations in speed and versatility. For example, the cutting speed of standard mechanical systems averages around 2 meters per minute. In contrast, laser machines can achieve speeds exceeding 15 meters per minute, particularly with thinner materials. However, laser machines require significant initial investment and maintenance. Businesses must assess the long-term benefits against these considerations.

Moreover, while laser machines produce less physical waste, they can create hazardous fumes depending on the material. Safety measures must be in place, which adds complexity. A recent survey indicated that 20% of users felt overwhelmed by the maintenance needs of laser systems. Businesses should reflect on whether they are prepared for these challenges while reaping the potential benefits.

Market Trends: Growth Projections for Laser Technology in Manufacturing

Laser technology is experiencing remarkable growth in the manufacturing sector. As industries evolve, the need for precision and efficiency is paramount. According to recent market projections, the demand for laser machines is set to rise significantly in the coming years. This surge is driven by advancements in laser technology and the increasing adoption of automation.

Tip: Investing in employee training is crucial. Proper training ensures that your staff can operate laser machines effectively. This leads to higher productivity and fewer errors.

Moreover, laser machines offer versatility across various applications. They can be used for cutting, engraving, and marking materials. As businesses look to optimize production capabilities, lasers provide a solution that meets diverse needs. It's essential to evaluate specific business requirements before making a purchase.

Tip: Assess your production volume before choosing a laser machine. A machine that is too powerful might be overkill. Conversely, a low-spec option may hinder your operations. Recognizing the right balance can save costs and enhance efficiency.

Applications of Laser Machines in Customization and Product Development

Laser machines have become essential tools for customization and product development across various industries. They offer precision and efficiency that traditional methods often cannot match. From engraving unique designs on promotional items to cutting intricate shapes in textiles, laser machines are versatile. Their ability to work with different materials—like wood, metal, and plastic—opens up many creative possibilities.

Customization is increasingly important in today's market. Businesses seek to offer unique products to stand out. Laser machines allow for personalized engravings or tailored designs. For instance, a small business can create custom awards or gifts with ease. However, it's crucial to recognize that even with advanced technology, crafting a perfect product requires skill and practice.

Mistakes can occur, such as misalignments or uneven finishes, which can affect the final output.

In product development, laser machines expedite prototyping. Designers can quickly create functional samples and test them. This rapid iteration is beneficial but may also lead to overlooking details. Some aspects—like finish quality or durability—might not be fully evaluated. Balancing speed and accuracy in this process is a challenge that many face. Embracing imperfections and learning from them is part of the improvement journey in laser technology.

Related Posts

-

10 Ways Laser Machines Revolutionize Global Manufacturing Efficiency

-

5 Tips to Maximize Efficiency with Your Laser Machine in Production Settings

-

Exploring the Future of Manufacturing with Advanced Laser Machine Technology

-

Unlocking the Advantages of Laser Machine Technology for Modern Manufacturing

-

How to Choose the Best Laser Cutter for Your DIY Projects in 2023

-

How to Choose the Right Laser Cutter for Your Business Needs