How to Choose the Best CO2 Laser Cutter for Your Projects and Needs

In today's highly competitive manufacturing environment, choosing the right tools for your projects is paramount. The CO2 laser cutter has emerged as a versatile solution, allowing users to execute intricate designs with precision and efficiency. According to a report by MarketsandMarkets, the global CO2 laser cutting machine market is projected to grow from $2.18 billion in 2020 to $3.63 billion by 2025, reflecting a significant increase in demand across various industries, from textiles to aerospace.

Industry expert Dr. Emily Carter, a leading authority on laser technologies, emphasizes the importance of selecting the right CO2 laser cutter for specific applications: "Understanding the unique capabilities and limitations of CO2 laser cutters is essential for any manufacturing professional aiming to optimize their production processes." This insight highlights the necessity for potential buyers to consider their specific needs and desired outcomes when evaluating different models and features in the CO2 laser cutter market.

With advancements in technology and design, there are numerous options available, making it crucial for users to assess factors such as power, size, and the materials they intend to work with. By taking these elements into account, individuals and businesses can make informed decisions that align with their project requirements and operational goals.

Understanding the Basics of CO2 Laser Cutters

When diving into the world of CO2 laser cutters, it’s essential to grasp the fundamental principles governing their operation. CO2 laser cutters use a gas mixture that produces a high-intensity beam of light, which can precisely cut or engrave a variety of materials, including wood, acrylic, glass, and even leather. Understanding the functioning of these machines can not only enhance your crafting projects but also improve your workflow.

Tip: Before investing in a CO2 laser cutter, consider the materials you plan to work with most frequently. Some machines excel with certain materials over others, influencing your decision. Additionally, pay attention to the wattage of the laser; higher wattage often equates to faster processing times and the ability to cut thicker materials.

Another crucial aspect is the cutting area size, which determines the maximum dimensions of the projects you can undertake. CO2 laser cutters come in various sizes, and selecting one that fits your workbench and project scale is imperative.

Tip: If you have limited space, opt for a model with a compact design. Additionally, keep an eye on features such as speed settings, software compatibility, and safety features, as these can greatly enhance your user experience and overall productivity in the workshop.

Identifying Your Project Requirements and Needs

When selecting a CO2 laser cutter, the first step is to clearly identify your project requirements and needs. Consider the types of materials you plan to work with, such as wood, acrylic, or textiles, as different materials may require varying levels of power and precision. Assess the thickness of these materials, as thicker options may necessitate a more powerful laser cutter. Additionally, think about the size of your projects; larger pieces will require a machine with a more extensive cutting area, while smaller projects may not need as much space.

Another crucial aspect to evaluate is the intended volume of work. If you envision high-volume production, look for a CO2 laser cutter that offers speed and efficiency features. On the other hand, if your projects are more infrequent or prototyping-based, a less powerful, more budget-friendly option could suffice. Don't forget to consider software compatibility, as being able to easily integrate your design software with the laser cutter can significantly streamline your workflow. Ultimately, by thoroughly analyzing your specific project demands, you can confidently choose a CO2 laser cutter that fits your unique needs.

How to Choose the Best CO2 Laser Cutter for Your Projects and Needs

| Model | Laser Power (W) | Maximum Speed (mm/s) | Working Area (mm) | Material Compatibility | Price ($) |

|---|---|---|---|---|---|

| Model A | 40 | 300 | 300 x 200 | Wood, Acrylic, Leather | 1,200 |

| Model B | 60 | 360 | 500 x 300 | Wood, Acrylic, Plastic | 2,500 |

| Model C | 80 | 400 | 600 x 400 | Wood, Acrylic, Leather, Fabric | 3,200 |

| Model D | 100 | 500 | 800 x 600 | Wood, Acrylic, Glass | 4,500 |

Evaluating Key Specifications and Features of CO2 Laser Cutters

When choosing a CO2 laser cutter, evaluating key specifications and features is essential to ensure it meets your project requirements. One of the primary specifications to consider is the power output of the laser. Typically measured in watts, higher power output translates to the ability to cut through thicker materials and achieve quicker processing times. For projects involving materials like acrylic, wood, or leather, a cutter with a power range of 40 to 100 watts is usually sufficient, while heavier applications may require more robust machines.

Another critical feature is the cutting area size, which determines the maximum dimensions of the material you can work with. An adequate bed size is crucial for larger projects, allowing for more versatility in design without the need for multiple setups. Additionally, the technology used for the laser cutter and its compatibility with different design files can greatly affect the user experience. Features such as adjustable focus, speed control, and built-in safety mechanisms also enhance the functionality and ease of use of the cutter, making them important factors to consider when selecting the right equipment for your needs.

Comparing Different Brands and Models for Performance

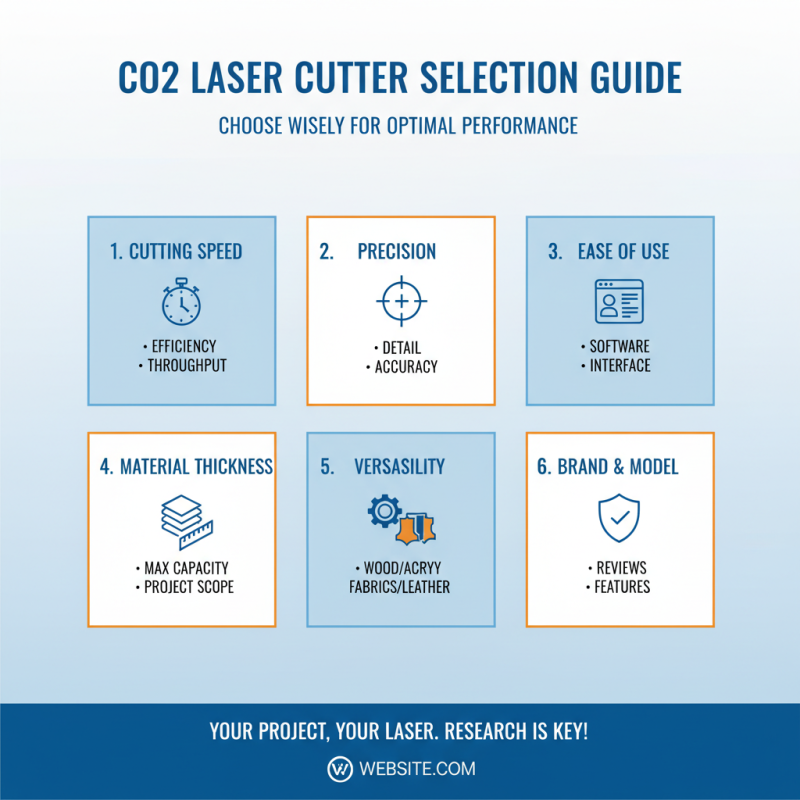

When selecting a CO2 laser cutter, understanding the performance of different brands and models is crucial for ensuring it meets your specific project requirements. Each model may offer varying features such as cutting speed, precision, and ease of use, which can significantly affect your workflow. It’s essential to consider the maximum material thickness that the laser cutter can handle and the range of materials it can efficiently process, as this will determine its versatility for different applications, from woodworking to engraving.

Additionally, examining customer reviews and expert opinions can provide insights into a model's reliability and durability. Many users prioritize features such as adaptability to software, maintenance requirements, and support services, as these factors can impact long-term usability. Comparing wattage options is also key; higher wattage typically translates to faster cutting speeds and the ability to work with denser materials. By collating performance metrics across different models, you can make an informed decision that aligns with your project goals and budget, ensuring you choose a CO2 laser cutter that not only performs well but also contributes to the efficiency of your crafting process.

Budget Considerations and Long-term Maintenance for CO2 Lasers

When considering the purchase of a CO2 laser cutter, budget becomes a significant factor. These machines range from affordable entry-level models to high-end versions with advanced features. It’s crucial to set a realistic budget that accounts not only for the initial purchase price but also for additional costs such as materials, accessories, and software. Prioritize features that align with your specific projects to avoid overspending on unnecessary capabilities.

**Tips:** Always include a cushion for unexpected expenses in your budget. Think about how much you plan to use the cutter; higher usage may justify a more expensive, durable model. Don’t forget to factor in the costs of essential materials and maintenance supplies.

Long-term maintenance is equally important to consider. Regular upkeep can prevent costly repairs and extend the life of your machine. Familiarize yourself with the required maintenance procedures, such as lens cleaning and cooling system checks. Create a maintenance schedule to ensure that your laser cutter remains in optimal condition.

**Tips:** Keep a log of maintenance tasks to track and manage your upkeep effectively. Consider online forums or local maker communities for shared maintenance tips and service recommendations. Doing your research upfront can save you both time and money in the long run.

Related Posts

-

Exploring CO2 Laser Cutter Innovations at the 138th Canton Fair 2025 in China

-

How to Choose the Right CO2 Laser Cutter for Your Business Needs

-

Understanding the Advantages of CNC Laser Cutters in Modern Manufacturing Processes

-

Ultimate Guide to Choosing the Right Laser Metal Cutting Machine for Your Business Needs

-

10 Ways Laser Machines Revolutionize Global Manufacturing Efficiency

-

5 Best Metal Laser Cutter Techniques for Precision Cutting