How to Choose the Right CNC Milling Machine for Your Projects

Choosing the right CNC milling machine for your projects can be a crucial decision that impacts the quality, efficiency, and precision of your manufacturing processes. With the technological advancements in computer numerical control (CNC) systems, these machines have become essential tools in various industries, from aerospace to automotive and beyond. The right CNC milling machine not only ensures accurate machining but also enhances productivity and reduces waste, making it an indispensable asset for any operation.

When selecting a CNC milling machine, it's essential to consider several factors, including the machine's size, capabilities, and compatibility with your specific materials. Additionally, understanding the various types of CNC milling machines available in the market can help you tailor your choice to meet your project requirements. As you embark on this decision-making journey, it's important to prioritize features that align with your production goals while also evaluating the long-term investment benefits of each machine. By doing so, you can ensure that your chosen CNC milling machine will effectively serve your needs and contribute to the success of your projects.

Understanding CNC Milling Machines and Their Applications

CNC milling machines are essential tools across various industries, providing precision and efficiency in manufacturing processes. Their applications range from automotive and aerospace to medical devices and consumer goods. According to a recent report by Market Research Future, the global CNC milling machine market is expected to reach over $100 billion by 2025, driven by the demand for high-quality, custom-engineered products. This growing market emphasizes the importance of selecting the right milling machine tailored to specific project requirements.

Understanding the diverse applications of CNC milling machines allows users to make informed choices. For example, 3D milling can produce complex geometries for bespoke parts in the aerospace sector, while high-speed milling is preferred for mass production of components in the automotive industry. A thorough comprehension of the capabilities and limitations of different CNC milling types is vital. In fact, research shows that companies using advanced CNC milling technology report a 30% increase in operational efficiency and a significant reduction in production errors, highlighting the critical role of these machines in modern manufacturing practices.

Comparison of Different CNC Milling Machines Based on Key Features

Key Factors to Consider When Choosing a CNC Milling Machine

When selecting the right CNC milling machine for your projects, several key factors should be taken into consideration to optimize performance and ensure efficiency. First and foremost, the machine’s specifications, such as its capabilities in terms of speed, precision, and versatility, play a crucial role. According to a report from the International Federation of Robotics, the average precision of modern CNC machines can reach up to ±0.002 mm, which significantly enhances the quality of intricate designs and high-tolerance parts. Additionally, the spindle speed is a vital aspect, with speeds typically ranging from 1500 to 24000 RPM, affecting material removal rates and surface finish quality.

Another critical factor is the type of materials you will be working with. Different CNC milling machines are designed to handle specific materials, such as aluminum, titanium, and various plastics. Understanding the material properties and the machining process required for them can help you choose a machine that minimizes tool wear and maximizes production efficiency. According to a study by the American Society of Mechanical Engineers, selecting the correct machine for the material can improve machining efficiency by up to 30%. Furthermore, considering the workspace available and the machine size is essential, as larger machines may offer more capabilities but can also require more significant investment and maintenance resources.

Types of CNC Milling Machines: Pros and Cons

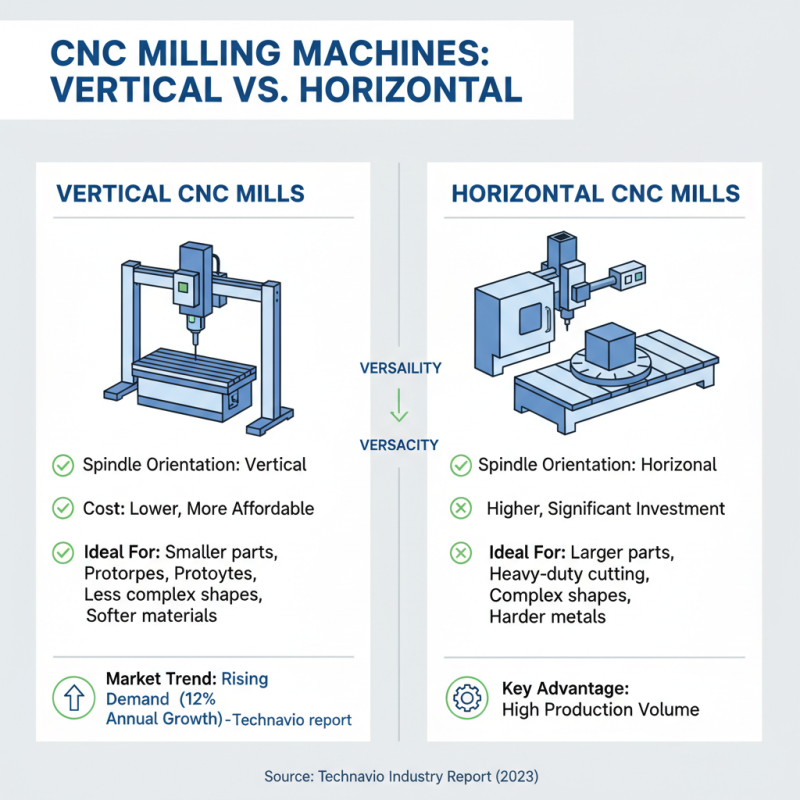

When selecting a CNC milling machine, understanding the various types available and their distinct advantages and disadvantages is crucial for optimizing your projects. The two primary categories are vertical and horizontal CNC milling machines. Vertical mills feature a vertically oriented spindle and are generally more cost-effective and simpler to use, making them ideal for smaller workshops or less complex operations. According to a recent industry report from Technavio, the global CNC milling machine market is expected to grow by approximately 12% annually, indicating a rising demand particularly for vertical setups due to their versatility in handling a variety of materials.

Horizontal CNC milling machines, on the other hand, provide greater precision and can handle larger workpieces more efficiently. They are adept at performing multiple machining operations simultaneously, which is beneficial for high-volume production. The downside is their higher initial cost and the need for more extensive floor space. A survey conducted by Market Research Future indicates that while horizontal machines only account for about 30% of the market, they are preferred for applications that require detailed and complex geometry due to their robust capabilities.

Both types of machines present unique pros and cons that can significantly impact your productivity and project outcomes. Careful consideration of your specific needs, considering factors like material types and production volume, will ultimately guide you to the right CNC milling solution.

Budgeting for Your CNC Milling Machine Purchase

When budgeting for your CNC milling machine purchase, it’s crucial to first determine the scope of your projects. The cost of CNC milling machines can vary significantly based on their capabilities, size, and features. Assessing your specific needs will help you identify which features are essential and which ones can be considered optional. For instance, if your projects require high precision and intricate detail, investing in a more advanced model may be necessary, whereas simpler tasks may be accomplished with a more basic unit.

Another important aspect of budgeting is not just the initial purchase price but also the long-term costs associated with owning and operating a CNC milling machine. This includes maintenance expenses, tool replacements, and any necessary upgrades in software or hardware. Additionally, you should factor in the potential cost savings that a more efficient machine may provide over time, such as reduced production times and waste. By taking a comprehensive look at the financial implications, you can make a more informed decision that aligns with your budget while meeting the demands of your projects.

Maintenance Tips for Long-Term Performance of CNC Milling Machines

Ensuring the long-term performance of CNC milling machines involves implementing routine maintenance practices tailored to the specific needs of the equipment. Research suggests that regular preventive maintenance can reduce machine downtime by up to 30%, which is critical for maintaining productivity in any manufacturing environment. Key maintenance activities include regularly checking and calibrating the machine's axes, inspecting and replacing worn parts, and ensuring that lubrication systems are functioning optimally. According to a report by the Association for Manufacturing Technology, companies that prioritize regular maintenance often experience a 20% increase in the lifespan of their milling machines.

In addition to standard checks, it's essential to maintain the cleanliness of the machine environment. Contaminants can significantly affect the machine's performance and precision. A study from the National Institute of Standards and Technology indicates that even minor contamination can lead to a 15% reduction in machining accuracy. Implementing a clean work area and using proper filtration systems in coolant and lubrication can mitigate these risks. Moreover, staff training on best practices for operation and maintenance can enhance the reliability of CNC machines, fostering a culture that prioritizes both productivity and machine care.

How to Choose the Right CNC Milling Machine for Your Projects - Maintenance Tips for Long-Term Performance of CNC Milling Machines

| Criteria | Details |

|---|---|

| Machine Type | Vertical, Horizontal, or 5-Axis |

| Workpiece Material | Aluminum, Steel, Plastic, Wood, etc. |

| Budget | $5,000 to $200,000+ |

| Precision Requirements | Tolerance levels in mm or inches |

| Size of Workpiece | Dimensions (L x W x H) depending on the machine specs |

| Maintenance Frequency | Daily, Weekly, Monthly based on usage |

| Common Maintenance Tasks | Lubrication, Calibration, Cleaning |

| Expected Lifespan | 10 to 25 years with proper maintenance |

Related Posts

-

What is the Process Behind CNC Metal Cutting Technology

-

10 Best CNC Metal Cutting Technologies That Boost Efficiency by 30 Percent

-

Unlocking the Future: How CNC Manufacturing is Revolutionizing Modern Production Techniques

-

Common Challenges Faced by Global Buyers When Choosing Metal CNC Machines

-

10 Essential Tips for Optimizing Your CNC Metal Cutting Process

-

How to Choose the Best CNC Metal Cutting Techniques for Your Manufacturing Needs