How to Choose the Best Laser Cutting Machine for Your Needs?

When selecting a laser cutting machine, it's crucial to consider various factors. These machines are versatile tools used in diverse industries. Choosing the right one can significantly impact your production efficiency and quality.

One must evaluate the specific needs of their projects. Different materials require different laser types and power settings. Additionally, the size of the workspace matters. A compact machine might fit perfectly in a small workshop, while larger projects demand bigger machines. It's all about balance.

Price is another vital consideration. High-quality laser cutting machines come with a significant investment. However, cheaper options may lack essential features. Reflect on what features truly matter to you. An informed decision will lead to better productivity and fewer regrets. The right laser cutting machine will not only meet your needs but also enhance your creative capabilities.

Understanding Your Laser Cutting Needs and Requirements

When selecting a laser cutting machine, understanding your needs is crucial. Consider the materials you'll work with. Common materials include wood, acrylic, and metal. According to a report by MarketsandMarkets, the laser cutting market will reach $5.4 billion by 2026, emphasizing the increasing demand for diverse applications.

The required power of a laser cutter can vary widely. If you're cutting thin materials, a low wattage machine might suffice. Yet, thicker materials necessitate machines with higher wattage. Industry analysis suggests that 20-50 watts is optimal for thin substrates. For metal, upwards of 100 watts is typical. Knowing this can save you from purchasing an unsuitable machine.

Think about operational efficiency as well. Speed and precision matter. However, higher speeds may affect the cut quality. Many users find this trade-off challenging. It’s essential to prioritize your cutting requirements over speed. Each application may require adjustments. This can lead to a learning curve, as many users report initial struggles with settings. Understanding these nuances can facilitate a better buying decision, aligning the machine’s capabilities with actual use cases.

Types of Laser Cutting Machines: CO2 vs. Fiber Lasers

When choosing a laser cutting machine, understanding the types available is crucial. Two common options are CO2 and fiber lasers. CO2 lasers use a gas mixture to produce a high-power beam. They are ideal for cutting organic materials like wood, acrylic, and leather. They cut smoothly and leave clean edges. However, they struggle with metals and may require regular maintenance.

On the other hand, fiber lasers use a solid-state method to generate the beam. This technology makes them more efficient, especially for cutting metals like stainless steel and aluminum. They are often faster and require less energy. Fiber lasers also have a longer operational life. But, they might be more expensive upfront. Each type has unique attributes and limitations.

Evaluating your materials and thickness is essential. If you mostly cut wood and plastic, CO2 may work best. Yet, if metal is your focus, fiber could be worth the investment. Consider your specific needs and the trade-offs involved. Each machine has its strengths. It’s important to weigh these carefully before making a decision.

Comparison of CO2 and Fiber Laser Cutting Machines

Key Features to Consider When Selecting a Laser Cutting Machine

When selecting a laser cutting machine, several key features can make a significant difference. Power is one of them. Higher wattage means better cutting speed and material versatility. However, this feature often comes with added cost. Balance your budget against your needs carefully.

Another important aspect is the cutting area size. A larger workspace allows for bigger materials. Yet, consider the space in your workshop. A machine that fits your area can help prevent future issues.

Tips for optimizing your choice:

1. Assess the materials you plan to cut. Different machines excel with specific types, like wood or metal.

2. Look into the software compatibility. A user-friendly interface can save time and frustration.

3. Don’t forget about maintenance. Some machines require more upkeep than others.

Keep in mind that additional features like speed control and cooling systems enhance performance. However, they can complicate your operation. Think about whether the benefits justify the learning curve.

Budgeting for Your Laser Cutting Machine: Costs and Financing Options

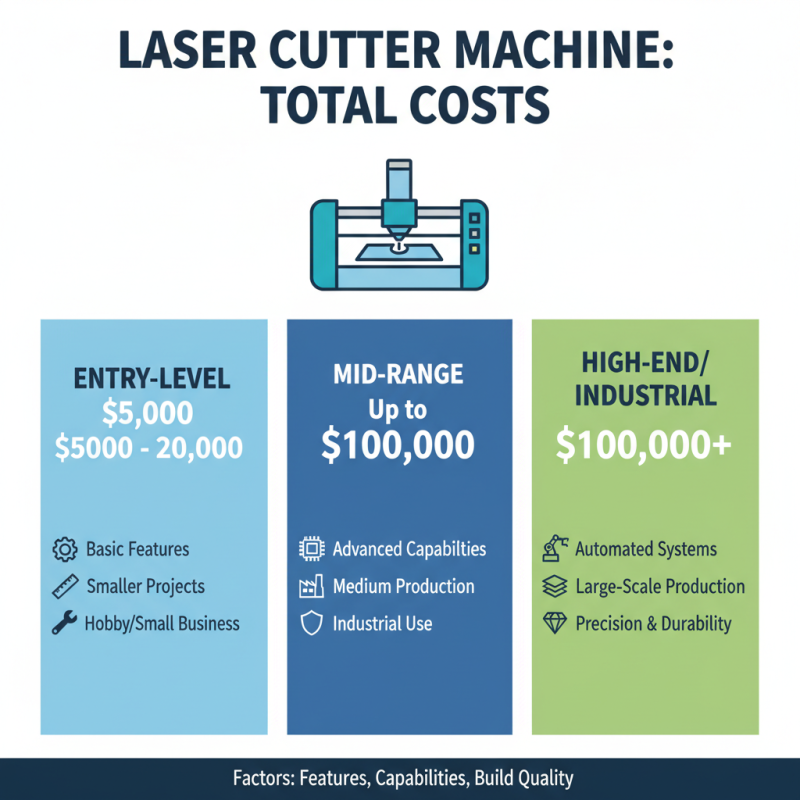

When budgeting for a laser cutting machine, understanding the total costs is essential. A recent industry report highlighted that entry-level machines can range from $5,000 to $20,000. Advanced models may exceed this range, going up to $100,000 or more. This wide range reflects features, capabilities, and build quality.

Financing options can help ease the burden. Many companies offer leasing plans or payment installments. In fact, data shows that approximately 25% of businesses choose to finance their equipment. This approach allows for better cash flow management. However, relying on financing also means considering interest rates, which can significantly impact the overall cost.

Moreover, maintenance costs are often overlooked. They can add up, sometimes reaching 10% of the initial investment annually. Regular maintenance ensures longevity, but unexpected breakdowns can lead to extra expenses. Taking these factors into account is crucial for realistic budgeting. Always revisit your initial plan and adjust it as needed. It’s a learning process.

Evaluating Supplier Reputation and After-Sales Support

When selecting a laser cutting machine, supplier reputation and after-sales support play critical roles. Industry reports indicate that 38% of buyers consider post-purchase support as a primary factor. A machine can be perfect on paper, but what if you encounter issues later? Solid support ensures efficiency in your production line.

Invest time in researching potential suppliers. Look for reviews and testimonials from other users. Websites like industry forums or dedicated review platforms can provide valuable insights. Consider this: suppliers with good after-sales service often report higher customer satisfaction rates. These companies may also offer training sessions and prompt response times.

Tips: Ask about warranty terms and typical response times. A responsive support team can save you money in the long run. Make sure to evaluate if their support speaks your language. Communication barriers can lead to confusion and delays. Don't overlook these details; they can make or break your experience with the machine.

How to Choose the Best Laser Cutting Machine for Your Needs?

| Feature | Description | Importance Rating (1-5) |

|---|---|---|

| Power Output | Determines the thickness of materials that can be cut. | 5 |

| Cutting Speed | Affects the efficiency and productivity of the machine. | 4 |

| Material Compatibility | Should support a diverse range of materials (metal, wood, acrylic). | 5 |

| Software Compatibility | Must work with CAD and design software for ease of use. | 4 |

| Customer Support | Assess the availability and quality of after-sales support. | 5 |

| Supplier Reputation | Research customer reviews and feedback on the supplier. | 5 |

| Price | Evaluate the machine's value against its capabilities and features. | 4 |

| Warranty | Check warranty length and conditions for repairs and replacements. | 5 |

Related Posts

-

Discover the Future of Precision with Laser Metal Cutting Machines in Modern Manufacturing

-

5 Best Metal Laser Cutter Techniques for Precision Cutting

-

How to Choose the Right Laser Cutter for Your Business Needs

-

7 Amazing Benefits of Using Laser Metal Cutting Machines for Precision Work

-

Exploring CNC Cutting Innovations at the 138th Canton Fair 2025 in China

-

Revolutionizing Precision: How Laser Metal Cutting Machines Transform Industries