How to Choose the Best Laser Cutter for Your Projects?

Choosing the right laser cutter can be daunting. With so many models and features, it's easy to feel overwhelmed. This decision impacts your projects significantly. A good laser cutter can enhance your creativity and efficiency. However, selecting the wrong one can lead to frustration and wasted resources.

Consider what materials you will work with. Different laser cutters excel at different tasks. Some are great for wood, while others handle metal better. Knowing your needs is vital. Research specifications like wattage, bed size, and cutting speed. These factors influence the machine's performance.

It's essential to reflect on your skill level too. Beginners may prefer user-friendly models. Advanced users might seek more features and capabilities. Assessing your project goals clearly can aid in decision-making. Sometimes taking the plunge is necessary for growth, but it’s crucial to make informed choices.

Understanding the Different Types of Laser Cutters Available

When choosing a laser cutter, understanding the different types available is key. There are CO2 and fiber laser cutters, each suited for specific materials. CO2 lasers are great for wood, acrylic, and fabric. They offer smooth cuts and can engrave well. Fiber lasers work better with metals and are faster. Choosing the right one depends on your project needs.

Tips: Consider the material you will work with. Do a test cut if possible. Check the thickness limits of the machine. It’s crucial for accuracy.

Another aspect to consider is the power of the laser cutter. Higher wattage means faster cutting speeds and deeper cuts. However, high power may not be necessary for all projects. It's important to find the sweet spot for your use case.

Tips: Reflect on your project scale. A lower wattage cutter may be sufficient for small crafts. Also, think about the workspace. Some cutters are bulky, taking up valuable room. Choose wisely!

How to Choose the Best Laser Cutter for Your Projects?

| Type of Laser Cutter | Best For | Cutting Thickness | Material Compatibility | Price Range |

|---|---|---|---|---|

| CO2 Laser Cutter | Wood, Acrylic, Leather | Up to 25 mm | Plastic, Wood, Fabric | $2,000 - $10,000 |

| Fiber Laser Cutter | Metals | Up to 20 mm | Steel, Aluminum, Brass | $3,000 - $15,000 |

| Diode Laser Cutter | Small Projects & Engravings | Up to 10 mm | Wood, Plastic, Fabric | $500 - $3,000 |

| UV Laser Cutter | High Precision Cutting | Up to 5 mm | Glass, Ceramics, Electronics | $10,000 - $50,000 |

Key Features to Consider When Choosing a Laser Cutter

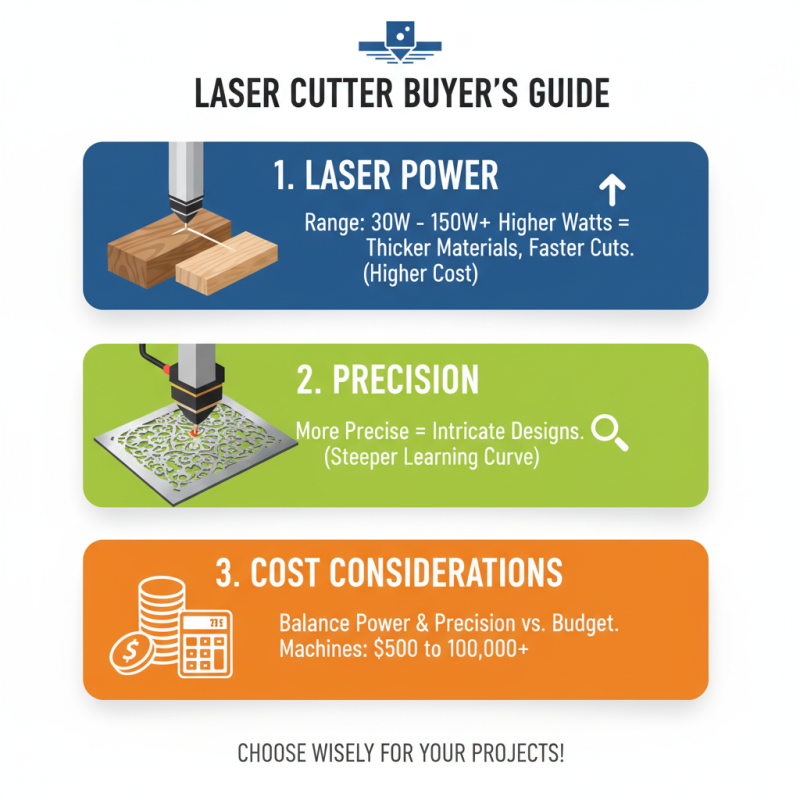

When choosing a laser cutter, several key features must be carefully considered. First, the laser power is crucial. Typically, machines range from 30W to 150W. A higher wattage cuts thicker materials more efficiently. However, high power often means higher costs. Precision also varies. A more precise laser can produce intricate designs but often comes with a steeper learning curve.

Material compatibility is another essential factor. Many cutters handle wood, acrylic, and certain metals. Still, specific machines may excel in one area while lacking in others. For instance, some units struggle with reflective surfaces. According to industry reports, about 25% of buyers regret their machine choice, citing limited material versatility as a common issue.

Lastly, software compatibility plays a significant role. Good software can enhance workflow but varies greatly across models. Some users find themselves frustrated with learning curves. A lack of user-friendly features often leads to wasted time. Research suggests that 40% of users prioritize software capabilities but underestimate their learning effort. Choosing a laser cutter wisely can make a significant difference in project outcomes.

Assessing Your Project Requirements and Material Compatibility

When selecting a laser cutter, assessing project requirements is crucial. Start by evaluating the materials you plan to work with. Different materials react uniquely to laser cutting. Wood, acrylic, and metal all require varying power settings and speeds. If you're focusing on intricate designs, some materials are better suited than others. Consider the thickness of your materials too. Thicker pieces often need more power and time to cut through effectively.

Next, think about the type of projects you plan to undertake. Simple shapes may need less precision than detailed engravings. If you're unsure, experiment with scrap pieces first. This approach allows for adjustments without wasting valuable materials. Another point to reflect on is the ventilation and safety of your workspace. Some materials can emit harmful fumes when cut. Ensure you have the right setup to handle these byproducts effectively.

It's also worth noting that what works for one project may not work for another. Your experience level matters, too. Beginners might struggle with complex materials, while seasoned users can tackle more challenging tasks. Keep in mind the learning curve associated with operating laser cutting equipment. Making mistakes is part of the process. Embrace them and analyze what went wrong. This reflection can guide future improvements and lead to more successful projects.

Budgeting: Finding a Laser Cutter That Fits Your Financial Plan

When budgeting for a laser cutter, it’s essential to define your needs. Consider the types of projects you plan to undertake. Will you work on small crafts or larger items? Each category has different requirements. This clarity sharpens your focus when comparing prices.

Laser cutters come in various price ranges. You might find lower-cost models that seem appealing. However, they often lack crucial features. Many budget options may not provide adequate precision or power. You could soon realize you need a costly upgrade. This is a common pitfall.

Pay attention to ongoing operational costs. Materials, maintenance, and replacement parts can add up over time. A cheaper initial purchase can quickly become expensive. Sometimes, a mid-range option is wiser. It could save you money in the long run. Prioritize features based on your project requirements, not just the price tag. This thoughtful approach will lead to more satisfying results.

Laser Cutter Price Comparison by Features

Evaluating Brand Reputation and Customer Support Before Purchase

Choosing the right laser cutter involves more than just technical specifications. Brand reputation plays a crucial role in your decision. Research the manufacturer's history. A reputable brand often offers better reliability and innovation. Look for products that have received positive feedback. Check online reviews for insights from other users.

When evaluating customer support, consider how responsive they are. Quick and helpful support can save you time and frustration. Find out if they offer warranties and support options like phone or online chat. This can make a significant difference if you face issues post-purchase.

Tips: Reach out to customer service before buying. Their response times can indicate their commitment. Don’t ignore user forums where enthusiasts share experiences and challenges. Engaging in these communities can help you gauge the real-world performance of the machine. Reflect on these aspects to make a more informed choice.

Related Posts

-

How to Choose the Right Laser Cutter for Your Business Needs

-

Exploring CO2 Laser Cutter Innovations at the 138th Canton Fair 2025 in China

-

Common Issues Faced in CNC Cutting Operations

-

Exploring the Future of Manufacturing: How Laser CNC Technology is Revolutionizing Production Processes

-

Unlocking Precision: How Metal Laser Cutters Transform Modern Manufacturing

-

10 Essential Tips for Mastering Laser CNC Technology