How to Use CNC Cutting Techniques for Precision Fabrication in 2025

In recent years, the manufacturing industry has increasingly embraced advanced technologies, with CNC cutting techniques emerging as a cornerstone for precision fabrication. According to a report by MarketsandMarkets, the global CNC machine market is projected to reach $117.5 billion by 2026, reflecting a compound annual growth rate (CAGR) of 6.0% from 2021 to 2026. This significant growth underscores the rising demand for automated and precise manufacturing solutions across various sectors, including automotive, aerospace, and electronics. The implementation of CNC cutting not only enhances productivity but also ensures superior quality and accuracy in the production of intricate designs.

As industries prepare for the technological advancements anticipated in 2025, the integration of CNC cutting techniques will play a vital role in meeting the evolving challenges of precision fabrication. Data from the International Federation of Robotics reveals that by 2023, the use of industrial robots, including CNC machines, is expected to surpass 3 million units worldwide. This trend highlights the increasing reliance on automation to boost efficiency and reduce operational costs. By understanding and mastering CNC cutting techniques, manufacturers can not only enhance their competitiveness in a rapidly changing market but also pave the way for sustainable growth and innovation in their fabrication processes.

Understanding CNC Cutting Techniques: An Overview for 2025

CNC cutting techniques have revolutionized precision fabrication, offering unparalleled accuracy and efficiency. As of 2025, the global CNC machine market is projected to reach over $100 billion, growing at a CAGR of 6.5% from 2022 to 2025, as reported by industry analysts. This growth underscores the increasing adoption of CNC technologies across various sectors, including automotive, aerospace, and electronics, where tolerances of just ±0.002 inches are often required. By leveraging CNC cutting methods, manufacturers can achieve intricate designs and maintain tight specifications that are essential for modern production standards.

Understanding the fundamentals of CNC cutting is crucial for maximizing its potential. Techniques such as laser cutting, plasma cutting, and water jet cutting each serve unique purposes and material compatibilities. For instance, laser cutting offers the ability to cut through thick materials with clean edges, making it ideal for metal and plastic fabrication. According to a study by Research and Markets, the laser cutting segment alone is expected to grow due to its efficiency and minimal material waste, positioning it as a preferred choice in diverse fabrication processes. As businesses invest in advanced CNC systems and skilled operatives, the ability to execute precise fabrications at scale will serve as a competitive advantage in the ever-evolving manufacturing landscape.

Key Benefits of CNC Cutting in Precision Fabrication

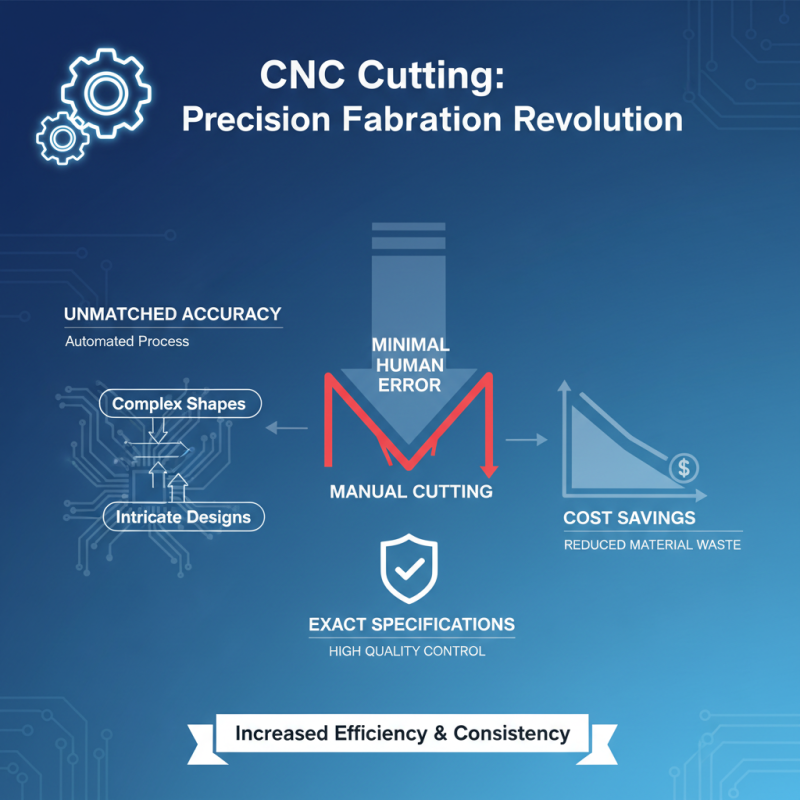

CNC cutting techniques have revolutionized precision fabrication by offering unmatched accuracy and efficiency. One of the key benefits of utilizing CNC cutting is the ability to produce complex shapes and intricate designs with minimal human intervention. This automated process minimizes the risk of errors that can accompany manual cutting methods, ensuring that the final products are manufactured to exact specifications. By eliminating inconsistencies, businesses can maintain high standards of quality control and reduce material waste, ultimately leading to cost savings.

Another significant advantage of CNC cutting in precision fabrication is its versatility across various materials, from metals to plastics. The adaptability of these machines allows for rapid adjustments in design, enabling manufacturers to respond swiftly to market demands or client requests. This capability not only enhances productivity but also fosters innovation, as engineers can experiment with new designs without the fear of extensive rework. As industries evolve, the reliance on CNC cutting will likely grow, making it an essential tool for future fabrication strategies.

Essential CNC Machines and Tools for Effective Cutting

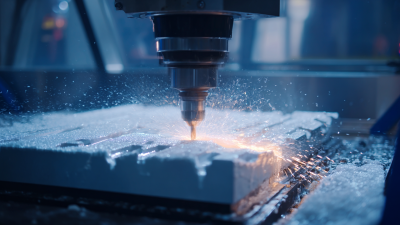

In the realm of precision fabrication, the selection of essential CNC machines and tools plays a crucial role in achieving optimal results. CNC milling machines, for instance, are indispensable for shaping materials with high accuracy. Equipped with advanced software, these machines are capable of executing intricate designs, making them ideal for both prototyping and large-scale production. Additionally, CNC routers offer versatility in cutting various materials, ranging from wood to plastics and metals, thereby widening the scope of fabrication possibilities.

Another key component in effective cutting is the use of CNC plasma and laser cutting machines. These tools provide exceptional speed and precision for metal fabrication tasks, allowing operators to create complex shapes with minimal material waste. Moreover, the introduction of automated tool changers enhances workflow efficiency by reducing setup time, which is particularly beneficial in fast-paced production environments. By embracing these essential CNC tools, manufacturers can ensure they remain competitive and precise in their cutting operations, paving the way for innovation in fabrication techniques.

Precision Fabrication Techniques Using CNC Cutting Machines in 2025

Best Practices for CNC Cutting Setup and Calibration

Setting up and calibrating CNC cutting machines is crucial for achieving precision in fabrication. The first step in the setup process is to ensure that the machine is placed on a stable and level surface, as any vibration or misalignment can lead to inaccuracies in the cutting process. After confirming the machine's stability, operators should proceed to calibrate the machine's axes. This involves moving each axis to its home position and then verifying the distances with precision measuring tools. Proper calibration ensures that the machine accurately understands its position, which is vital for intricate designs.

Next, selecting the appropriate cutting tools and settings plays an essential role in the outcomes of CNC cutting. Choosing the right tool for the material being cut is imperative; different materials require specific types of bits to ensure clean cuts without damaging the workpiece. Furthermore, adjusting the feed rate and spindle speed according to the material thickness and type will significantly enhance cutting efficiency and precision. Regularly monitoring and fine-tuning these parameters based on test cuts can help identify the optimal settings for consistent results. Emphasizing these best practices for setup and calibration lays the foundation for effective and precise CNC machining in any fabrication project.

Future Trends in CNC Technology and Precision Fabrication Applications

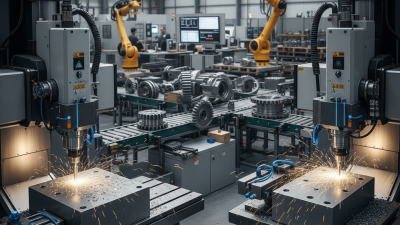

As we progress through 2025, the landscape of CNC technology and precision fabrication is witnessing remarkable advancements that are reshaping industry applications. One of the most significant trends is the integration of artificial intelligence and machine learning into CNC systems. These technologies enhance the capabilities of traditional CNC machines by enabling smarter automation, improved predictive maintenance, and real-time monitoring of production processes. This level of intelligence not only optimizes efficiency but also significantly reduces downtime and operational costs, making precision fabrication more reliable and sustainable.

Another emerging trend in CNC technology is the rise of advanced materials and flexible manufacturing techniques. With the advent of new composite materials and additive manufacturing processes, fabricators can push the boundaries of design and functionality. CNC cutting techniques are adapting to accommodate these materials, which allows for the creation of complex geometries that were previously unattainable with conventional methods. This evolution in material usage not only improves product performance but also broadens the scope of applications, which is essential for industries such as aerospace, automotive, and healthcare.

As these trends continue to evolve, the future of precision fabrication looks promising, marked by innovation and efficiency.

Related Posts

-

Exploring CNC Cutting Innovations at the 138th Canton Fair 2025 in China

-

How to Choose the Best CNC Metal Cutting Techniques for Your Manufacturing Needs

-

Why CNC Metal Cutting is Essential for Modern Manufacturing Efficiency

-

Common Issues Faced in CNC Cutting Operations

-

The Definitive Ultimate Guide to Mastering CNC Cutting Techniques for Precision Fabrication

-

10 Essential Tips for Optimizing Your CNC Metal Cutting Process