What is a CNC Laser Cutter and How Does it Work?

CNC laser cutters have revolutionized the manufacturing industry. With precision and speed, they offer unmatched capabilities in cutting various materials. According to industry reports, the global CNC machine market is projected to reach $117 billion by 2025, driven by advancements in automation, including laser cutting technology. The CNC laser cutter is a pivotal tool utilized across diverse sectors, from woodworking to aerospace.

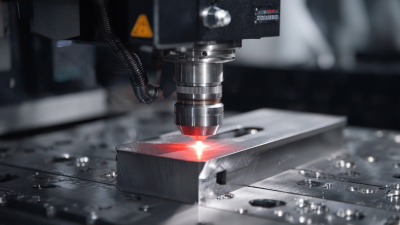

These machines utilize a focused laser beam to cut through materials like metal, plastics, and wood. The accuracy of a CNC laser cutter can reach tolerances as fine as 0.1 mm. This precision allows for complex designs that were once difficult to produce. However, there are challenges involved. The initial cost of these machines can be prohibitive for small businesses. Moreover, the need for skilled operators adds another layer of complexity to the operational process.

Despite these hurdles, the benefits are substantial. Efficiency in production can increase significantly. Many companies have reported a decrease in waste material, showcasing both economic and environmental advantages. As industries continue to evolve, the CNC laser cutter remains essential but prompts reflection on balancing innovation with accessibility.

What is a CNC Laser Cutter?

A CNC laser cutter is a powerful tool used for precise cutting and engraving. It operates by using a focused beam of light to slice through materials such as wood, metal, or plastic. The term "CNC" stands for Computer Numerical Control, which indicates how the machine operates. It follows a pre-programmed design, allowing for intricate shapes and patterns.

These machines are equipped with a laser that can be adjusted for various thicknesses. Users input designs via design software, which the cutter translates into movements. This process is highly efficient and can yield complex work. However, there are challenges. Misalignment can occur, leading to imperfect cuts. Learning the software can be daunting for beginners.

The laser cutter's precision is admirable, but it requires careful calibration. Users must consider factors like material type and thickness. The potential for errors is real, especially when creating detailed designs. For those exploring this technology, taking the time to experiment and reflect on the results is essential. Even the best designs may need tweaking.

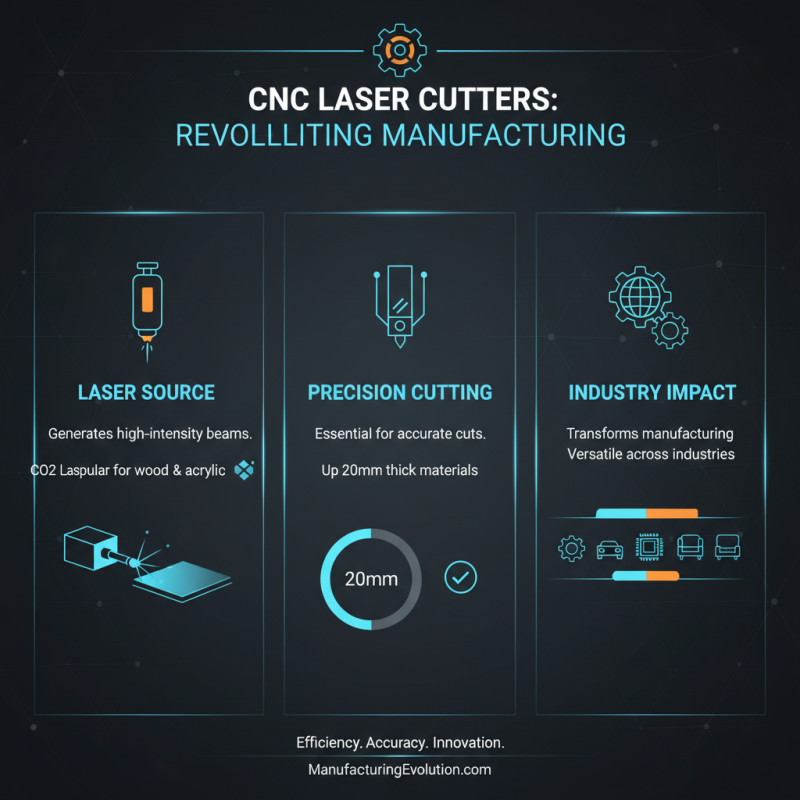

The Basic Components of CNC Laser Cutters

CNC laser cutters are revolutionizing manufacturing processes across various industries. At the heart of a CNC laser cutter are several key components. The laser source generates high-intensity beams, essential for precise cutting. CO2 lasers are popular, especially for materials like wood and acrylic. Data shows that lasers can cut through materials up to 20 mm thick with remarkable accuracy.

Another critical component is the motion system. This system controls the laser head's movements across the material. Servo motors or stepper motors guide the laser, ensuring efficient cutting paths. Reports indicate that CNC machines can enhance productivity by up to 60% compared to traditional cutting methods. However, this system also requires regular calibration, as misalignments can lead to errors and wasted materials.

The control software is equally important. It translates design files into instructions for the cutter. User-friendly interfaces are becoming more common, but challenges remain. Many users struggle with integrating new software into existing workflows. Moreover, the learning curve can be steep for those unfamiliar with CAD programs. These aspects highlight the need for continuous training and adaptation in the rapidly evolving landscape of CNC laser cutting technology.

How CNC Laser Cutters Operate Step-by-Step

CNC laser cutters are fascinating devices. They use a high-powered laser to cut materials with precision. Understanding how they operate can help improve your projects.

The process begins with setting up the machine. Follow the instructions carefully. It's crucial to calibrate the laser correctly. Next, choose the material you want to cut. Popular options include wood and acrylic. Each material requires specific settings. Always double-check these settings to avoid mistakes.

Once ready, load the design file into the software. The machine will interpret this file. Then, watch as the laser moves along the designated path. This part is mesmerizing. As it cuts, it produces a clean edge without any roughness.

Tips: Always wear appropriate safety gear. The laser emits intense light. Improper eye protection can harm your vision. Additionally, keep the area clean. A cluttered workspace can lead to accidents. Lastly, don't rush the cutting process. Take your time to ensure accuracy. Remember, small errors can result in significant flaws later on.

What is a CNC Laser Cutter and How Does it Work?

| Component | Function | Material Compatibility | Max Cutting Thickness (mm) |

|---|---|---|---|

| Laser Source | Generates the focused beam of light | Metals, Plastics, Wood | 20 |

| Optics System | Focuses the laser beam on the material | Metals, Plastics, Wood | 15 |

| CNC Control System | Controls the movement of the laser along the material | Metals, Plastics, Wood, Acrylic | 25 |

| Material Table | Holds and supports the material during cutting | Metals, Plastics, Wood | 10 |

| Exhaust System | Removes fumes and debris created during cutting | All materials | N/A |

Applications of CNC Laser Cutting Technology

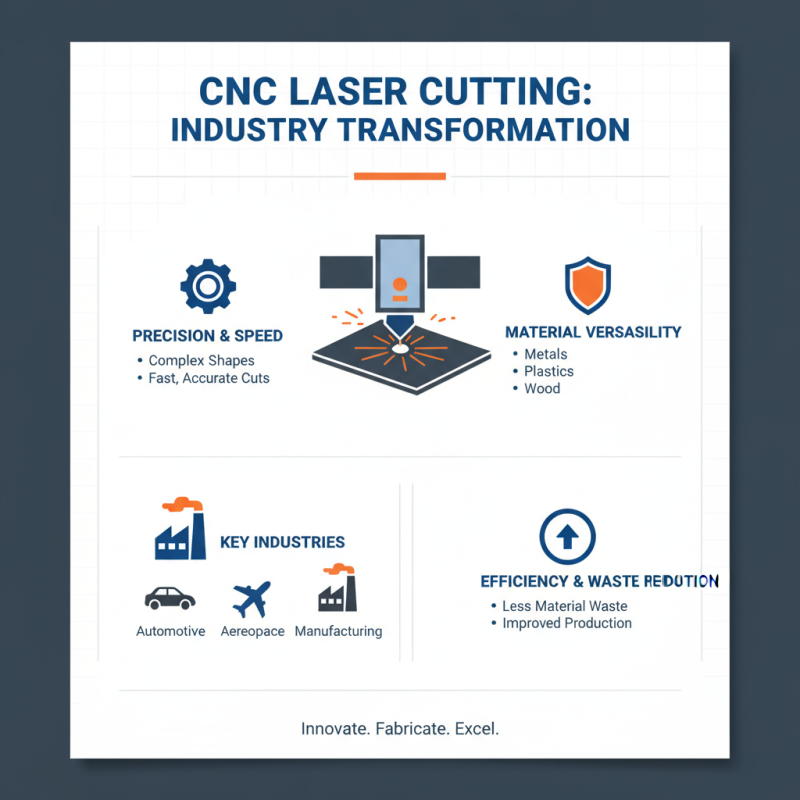

CNC laser cutting technology is transforming various industries. It is widely used in manufacturing, automotive, and aerospace sectors. These machines offer precision in cutting materials like metals, plastics, and wood. They can create complex shapes with speed and accuracy. As a result, they reduce waste and improve efficiency.

In the fashion industry, CNC laser cutters enable intricate designs on fabrics. Designers can produce unique patterns quickly. This capability allows for greater creativity and customization. Additionally, in the signage sector, businesses use laser cutters to create signs that are detailed and visually striking.

While CNC laser cutting provides many advantages, challenges exist. The initial setup and calibration can be time-consuming. Also, working with different materials requires specific settings. Proper training is essential to maximize the machine's potential. Not everyone may achieve perfect results on their first attempt. Learning from mistakes is a vital part of the process.

Advantages and Limitations of CNC Laser Cutters

CNC laser cutters are powerful tools that offer precision and versatility. These machines use focused laser beams to cut materials. They are efficient and can produce intricate designs with ease. However, there are both advantages and limitations to consider.

One major advantage is the precision of the cuts. CNC laser cutters can create complex shapes that are difficult to achieve with traditional methods. This accuracy is beneficial in industries like automotive and aerospace. They also work on various materials, including wood, metal, and plastic. This flexibility allows for creativity and innovation.

On the downside, the initial cost can be high. Not everyone can afford to invest in such technology. Maintenance can also be a challenge. Laser cutters require regular upkeep to ensure they function correctly. Since the technology is advanced, it may need specialized training. This can be a barrier for small businesses or hobbyists.

Tip: Always keep safety in mind. Protective eyewear is essential when operating laser cutters.

Tip: Start with simpler projects if you are new. This helps build your skills without overwhelming you.

Exploring limitations is as important as understanding advantages. Cutting thick materials might lead to uneven edges. This is a common issue and requires skill to manage. Taking time to practice can help overcome these challenges.

Related Posts

-

How to Choose the Right CO2 Laser Cutter for Your Business Needs

-

How to Choose the Best CO2 Laser Cutter for Your Projects and Needs

-

How to Choose the Best Laser Cutter for Your DIY Projects in 2023

-

Unlocking Precision: The Ultimate Guide to 2025's Top CNC Laser Cutters and Their Applications

-

Understanding the Advantages of CNC Laser Cutters in Modern Manufacturing Processes

-

Discover the Future of Precision with Laser Metal Cutting Machines in Modern Manufacturing