Why is CNC Manufacturing Essential for Modern Industries?

In today's rapidly evolving industries, CNC manufacturing plays a critical role. This technology embodies precision and efficiency. It is a powerhouse for sectors such as aerospace, automotive, and electronics. By automating machining processes, CNC manufacturing reduces human error. However, relying solely on machines can also be a double-edged sword.

Consider how CNC manufacturing enhances productivity. Machines can operate continuously, producing high volumes of parts with consistency. Yet, this could lead to a lack of skilled labor. The demand for skilled operators remains crucial. Industries must balance automation with human expertise.

Moreover, CNC manufacturing influences design innovation. Engineers can create complex shapes that were once impossible. This opens doors for creativity and customization. Still, it prompts questions about traditional craftsmanship. Are we losing touch with manual skills? As we embrace technology, we must reflect on its impact on our workforce and craftsmanship. The evolution of CNC manufacturing is not just a technological shift; it is a cultural one as well.

The Evolution of CNC Manufacturing in Modern Industries

CNC manufacturing has dramatically evolved over the past few decades. Initially, it was limited to simple tasks. Today, it plays a crucial role across various industries. The introduction of computer programming transformed manufacturing processes. Machines became more precise and efficient. It changed how products are designed and made.

Various industries have benefited from these advancements. Aerospace, automotive, and electronics companies use CNC to produce complex components. Design changes can be made quickly, which saves time. However, relying too much on technology has its downsides. Machines can malfunction unexpectedly. This can disrupt production schedules. It highlights the need for skilled workers who can troubleshoot these issues.

Tips for integrating CNC into your processes: Invest in training for your team. Understanding programming improves productivity. Regular maintenance of CNC machines can prevent downtime. Don't ignore the human element. A blend of technology and skilled workers can drive innovation. Balancing efficiency with adaptability is key for growth.

Growth of CNC Manufacturing in Industries (2010-2023)

Key Benefits of CNC Manufacturing for Production Efficiency

CNC manufacturing is a game changer in modern industries. Its precision significantly boosts production efficiency. Machines operate with high accuracy. This reduces waste and improves product quality. Parts are produced with exact specifications, limiting the chance for error. Companies can expect fewer defects, leading to higher customer satisfaction.

Additionally, CNC machines can run continuously. They require minimal human intervention, allowing workers to focus on other tasks. This creates a more streamlined workflow. Complex designs that were once impossible can now be achieved easily. However, not all companies fully utilize these machines. Some struggle with training staff to operate them effectively.

Cost is another factor to consider. Initial investments can be high, and not every business can afford it. The potential for reduced labor costs can be overlooked as well. While CNC technology offers many advantages, some organizations may experience a learning curve. Embracing this technology is essential but not without challenges. Each company needs to reflect on its readiness for such an investment.

Applications of CNC Machining Across Various Sectors

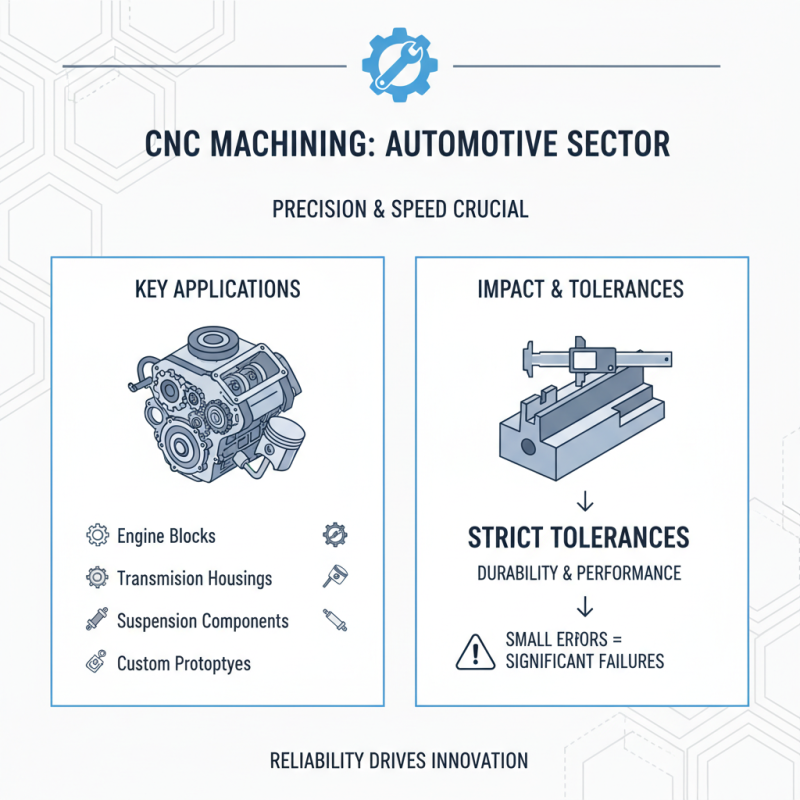

CNC machining plays a pivotal role across various sectors. In the automotive industry, precision and speed are crucial. CNC machines create complex parts like engine blocks and transmission housings. These parts must adhere to strict tolerances to ensure durability. However, even small errors in machining can lead to significant failures.

In the aerospace sector, safety is paramount. Components such as turbine blades undergo CNC machining to achieve precise specifications. These components help improve fuel efficiency and performance. Yet, maintaining these standards is challenging. Manufacturers must constantly assess their processes to avoid costly mistakes.

Healthcare also benefits from CNC technology. Surgical instruments and implants require utmost precision. CNC machining ensures these items are tailored to patient needs. Still, the need for ongoing training and adaptation is vital in this rapidly evolving field. Errors in production can directly impact lives. This highlights the need for careful attention to detail.

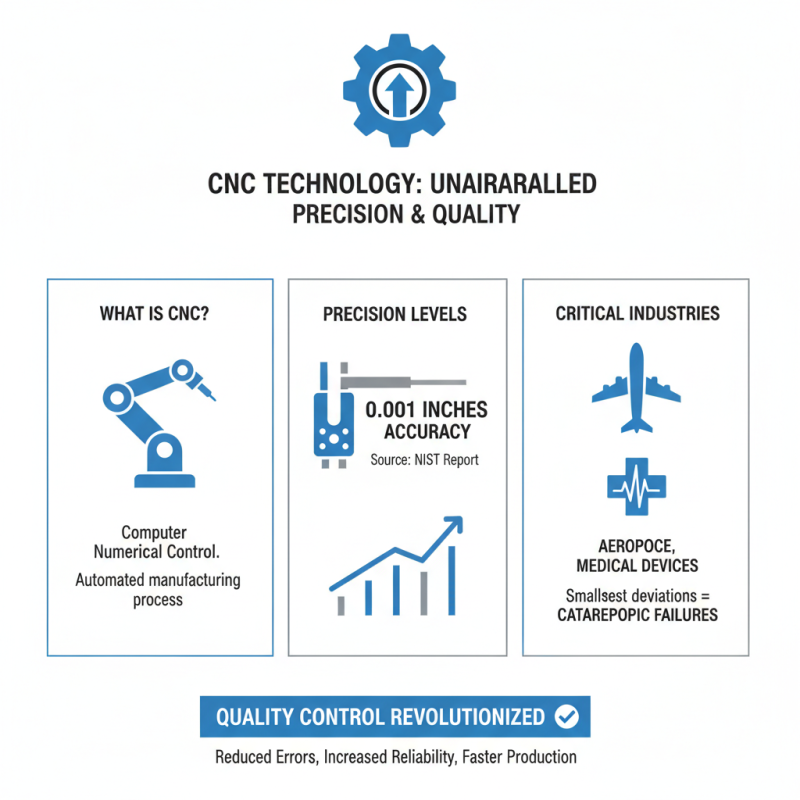

Impact of CNC Technology on Precision and Quality Control

CNC technology has revolutionized precision and quality control in modern manufacturing. A report from the National Institute of Standards and Technology indicates that companies using CNC machines can achieve precision levels within 0.001 inches. This accuracy is vital for industries like aerospace and medical devices, where small deviations can lead to catastrophic failures.

Moreover, CNC manufacturing reduces human error. A study found that automated processes can decrease defects by about 30%. Still, reliance on technology has its pitfalls. Over-automation can lead to skill degradation among workers. As more companies adopt CNC systems, a balance must be struck between automation and craftsmanship.

CNC also allows for better quality monitoring. Using real-time data analytics, manufacturers can detect issues early. Yet, data management can be challenging. Not all companies are equipped to analyze vast amounts of information efficiently. As technology evolves, continuous adaptation will be essential for improving precision without losing the human touch. Creating a culture of constant learning will help address these challenges.

Future Trends in CNC Manufacturing and Industry Adaptation

CNC manufacturing plays a crucial role in today's industries. As technology evolves, so does the landscape of CNC. Companies must adapt rapidly to stay competitive. The integration of artificial intelligence is transforming CNC operations. Machines can now learn from patterns and improve efficiency. This shift reduces downtime and enhances productivity.

Current trends reveal a push towards automation. More industries are automating their CNC processes. This change minimizes human error, but it raises concerns. Are we relying too much on machines? The balance between automation and human oversight is delicate. While machines excel in precision, creativity often comes from human input.

Sustainability is another emerging trend. Companies are seeking eco-friendly materials and processes. However, adopting sustainable practices can be challenging. There is still the question of cost versus benefit. Industries must weigh immediate costs against long-term gains. This requires careful planning and commitment. Innovation in CNC manufacturing continues to evolve, and industries must keep pace.

Related Posts

-

2025 Top 10 Trends in CNC Manufacturing Revolutionizing the Industry

-

Unlocking the Future: How CNC Manufacturing is Revolutionizing Modern Production Techniques

-

How to Choose the Right CNC Milling Machine for Your Projects

-

Ultimate Guide to Mastering CNC Turning Techniques for Precision Engineering

-

Common Challenges Faced by Global Buyers When Choosing Metal CNC Machines

-

10 Essential Tips for Optimizing Your CNC Metal Cutting Process