How to Effectively Use Laser Cut Aluminum in Your Projects Guide 2025

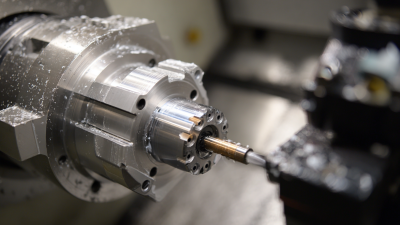

In the rapidly evolving world of design and manufacturing, laser cut aluminum has emerged as a game-changer for various projects, ranging from intricate art pieces to functional components in machinery. As John Smith, a renowned expert in the field of laser technology, once stated, "The precision and versatility of laser cut aluminum open up new horizons for creativity and innovation." This sentiment encapsulates the growing importance of this material in modern projects, where efficiency and detail are paramount.

Laser cut aluminum not only offers a lightweight solution but also enables unparalleled accuracy, making it an ideal choice for both aesthetic and structural applications. As designers and engineers seek to push the boundaries of their creations, understanding how to effectively utilize laser cut aluminum becomes essential. This guide aims to provide valuable insights into best practices, techniques, and tips for integrating this remarkable material into your projects, ensuring that you harness its full potential for achieving outstanding results.

Benefits of Using Laser Cut Aluminum in Modern Projects

Laser cut aluminum has emerged as a popular choice in modern projects due to its exceptional benefits. One notable advantage is its precision; laser cutting technology allows for incredibly accurate cuts and designs, leading to high-quality components that meet stringent specifications. This precision reduces material waste and ensures that every piece contributes effectively to the overall project, making it an economically sound option for designers and manufacturers alike.

In addition to precision, laser cut aluminum offers versatility in design. It can be manipulated to create intricate patterns and shapes that would be difficult or impossible to achieve with traditional manufacturing methods. This flexibility enables creative freedom for architects, engineers, and artists, allowing them to push the boundaries of their projects. Moreover, aluminum's lightweight nature combined with its strength makes it ideal for applications where weight reduction is crucial, without sacrificing durability. Overall, the use of laser cut aluminum enhances functionality and aesthetic appeal in modern project designs.

How to Effectively Use Laser Cut Aluminum in Your Projects Guide 2025 - Benefits of Using Laser Cut Aluminum in Modern Projects

| Dimension | Description | Benefit |

|---|---|---|

| Weight | Aluminum is lightweight compared to other metals. | Easier to handle and transport. |

| Durability | Highly resistant to corrosion and wear. | Longer lifespan and reduced maintenance costs. |

| Precision | Laser cutting allows for intricate and detailed designs. | High accuracy in manufacturing components. |

| Flexibility | Can be cut into various shapes and sizes. | Versatile for different project requirements. |

| Cost-Effectiveness | Efficient use of material with minimal waste. | Lower overall project costs. |

Understanding the Laser Cutting Process for Aluminum

The process of laser cutting aluminum has transformed the way manufacturers and fabricators approach metalwork in recent years. Laser cutting utilizes a focused beam of light to precisely slice through materials, leading to clean and accurate cuts with minimal waste. According to a report by *MarketsandMarkets*, the global laser cutting market is anticipated to grow from $5.2 billion in 2020 to $7.3 billion by 2025, showcasing the increasing reliance on this technology across various industries.

Understanding the laser cutting process for aluminum involves recognizing its key advantages. The high-energy precision of lasers allows for intricate designs that would be challenging to achieve with traditional cutting methods. Moreover, advancements in laser technology, such as fiber lasers, have made it possible to cut thicker aluminum sheets more effectively. Research from the *National Institute of Standards and Technology* highlights that lasers can provide cutting speeds up to ten times faster than conventional cutting techniques, signifying a substantial enhancement in productivity.

Furthermore, the flexibility of laser cutting makes it suitable for various applications, from aerospace components to artistic creations. This versatility is reflected in the wide range of aluminum alloys that can be processed, allowing designers to choose materials based on specific mechanical properties. As reported by the *American Welding Society*, the use of laser cutting in fabrication can reduce production costs by approximately 30%, underscoring the financial benefits of adopting this cutting-edge technology in projects.

Essential Tools and Materials for Laser Cutting Aluminum

When embarking on projects involving laser cut aluminum, understanding the essential tools and materials is paramount to achieving precision and efficiency. The primary tool required is a high-quality laser cutter capable of handling aluminum, which generally requires a laser with a power output ranging from 100 to 300 watts. According to industry data, utilizing lasers with at least 150 watts will significantly improve cutting speed and quality, allowing users to tackle thicker materials with ease.

In addition to the laser cutter, it is crucial to invest in appropriate safety gear, including laser safety goggles, gloves, and protective clothing, as aluminum cutting can produce harmful fumes and high temperatures. A proper ventilation system or fume extractor is recommended to maintain a safe working environment and comply with occupational health standards. Materials such as aluminum sheets or extrusions, often sourced in various grades and thicknesses, are necessary for diverse applications. Data from a recent market analysis indicates that the demand for aluminum in manufacturing processes has surged by over 5% annually, highlighting the importance of these materials in industry developments.

Lastly, utilizing software specifically designed for laser cutting can streamline the design process. CAD or CAM software aids in creating precise designs that account for laser kerf and material properties, ensuring efficient use of resources. As the laser cutting technology evolves, staying updated with the latest tools and techniques will enhance project outcomes and maintain competitiveness in an increasingly advanced industry.

Design Considerations for Laser Cut Aluminum Projects

When designing with laser cut aluminum, several considerations significantly enhance both the aesthetic and functional aspects of your project. According to a report by the Modern Machine Shop, laser cutting technology has become a favored choice due to its precision and efficiency, enabling manufacturers to achieve tight tolerances with minimal material waste. The high level of accuracy in dimensional cuts can reduce the need for secondary operations, thereby lowering overall production costs and timelines.

One key factor to consider is the thickness of the aluminum being used. Industry standards suggest that aluminum sheet thickness typically ranges from 0.5 to 10mm for various applications. Thinner sheets provide ease of cutting and intricate design possibilities; however, they may compromise structural integrity. Conversely, thicker aluminum offers durability but may require more powerful laser systems and longer processing times, thus affecting project turnaround. Additionally, factors such as grain direction, surface finish, and the intended end use of the final product should inform the design phase, ensuring that the resulting pieces meet both aesthetic and functional requirements seamlessly.

Safety Guidelines and Best Practices for Laser Cutting

When engaging in laser cutting aluminum, adhering to safety guidelines is paramount to ensure a secure working environment. According to the Occupational Safety and Health Administration (OSHA), more than 300,000 injuries occur annually in the manufacturing sector, many of which are related to equipment use. Prioritizing safety measures such as wearing appropriate personal protective equipment (PPE) like gloves, goggles, and protective clothing can significantly decrease the risk of personal injury. Furthermore, maintaining a clean workspace helps prevent accidents caused by tripping hazards or unintended interactions with equipment.

To optimize the laser cutting process and ensure a high quality of work, operators should be well-versed in best practices. Proper setup of the laser cutting machine, including focusing the beam and calibrating settings based on the material's thickness, can mitigate potential issues. A report by the Fabricators and Manufacturers Association states that nearly 50% of production downtime is linked to improperly configured equipment. Regular maintenance checks of the laser cutting machine also play a vital role in enhancing performance and extending the machine's lifespan. By fostering a culture of safety and operational excellence, projects utilizing laser-cut aluminum can achieve both efficiency and precision.

Laser Cutting Aluminum Utilization in Projects - 2025

Related Posts

-

Understanding the Efficiency of Laser Cut Aluminum Compared to Traditional Methods

-

How to Achieve Precision with Aluminum Machining Techniques

-

Solutions for Efficient Laser Cut Aluminum Manufacturing in a Competitive Global Market

-

How to Choose the Right CNC Aluminum Machining Process for Your Project

-

Unlocking Precision: The Future of Aluminum Machining in Modern Manufacturing

-

What is Aluminum Machining and How Does it Benefit Your Industry