10 Essential Tips for Using a CNC Milling Machine Effectively?

Using a CNC milling machine can be a game-changer for precision machining. Many beginners find it daunting. Mastering this technology requires practice and knowledge. This article aims to provide essential tips for effective operation.

Maintaining the CNC milling machine is crucial. Regular checks can prevent costly breakdowns. Operators must understand the tools and materials they will be using. Choosing the right tool can make a significant difference. Additionally, it's vital to have a clear plan before starting any project.

Mistakes often happen, especially for those new to CNC milling. Learning from these errors can lead to improvements. Being aware of common pitfalls is part of the journey. Every operator should reflect on their process and adapt strategies. Embracing a continuous learning mindset is key to mastering the CNC milling machine.

Understanding the Basics of CNC Milling Machines

CNC milling machines represent a remarkable advancement in manufacturing. They automate the machining process, allowing for precision and consistency. Understanding the basics is essential. For instance, familiarizing yourself with the machine's components, like the spindle and tool holder, is crucial. Each part has a unique function that impacts the final product.

The programming aspect can be daunting. Machinists often need to write G-code, the language of CNC machines. Mistakes in coding can lead to errors and waste. Setting the right parameters and understanding the material properties also matter. The machine’s speed and feed rate should match the type of material being used; otherwise, inefficiencies occur.

Additionally, regular maintenance cannot be overlooked. Clean the machine after each use to prevent debris buildup. Neglecting this can lead to issues down the line. Remember, achieving high-quality results takes practice and patience. Mistakes will happen, and it’s part of the learning curve. Embrace those challenges to improve your skills.

Key Safety Practices When Operating CNC Milling Machines

CNC milling machines are powerful tools. However, safety must come first in any workshop. According to a report by the Occupational Safety and Health Administration (OSHA), over 1,300 injuries occur annually from machine operation. This stark number highlights the importance of adhering to safety practices.

Wearing proper personal protective equipment (PPE) is essential. Safety goggles, gloves, and ear protection should be part of your daily gear. Ensure that long hair or loose clothing is secured. Even a brief distraction can lead to serious accidents. Inadequate attention has led to faulty setups, causing damage to both the machine and the operator.

Before operating a CNC milling machine, inspect it thoroughly. Look for frayed wires or loose parts. A study by the National Institute for Occupational Safety and Health (NIOSH) revealed that equipment malfunctions contribute to 43% of workplace injuries. Operators should also receive comprehensive training. Workers unfamiliar with their machines are more likely to overlook safety protocols, leading to potentially hazardous outcomes. Safety protocols might seem tedious, but they save lives and tools alike.

Essential Maintenance Tips for CNC Milling Machine Longevity

CNC milling machines are essential for precision engineering. Proper maintenance ensures their longevity and efficiency. Research indicates that regular maintenance can extend machine life by up to 30%. It is crucial to adopt a few key practices.

Tip: Regularly check and replace the coolant. Old or contaminated coolant can wear out tooling and affect machining accuracy. This simple step can prevent costly repairs.

Additionally, clean the machine daily. Dust and debris often lead to decreased performance. A dirty machine can introduce errors and reduce production quality. It can be tempting to overlook cleanliness, but neglect can cost more in the long run.

Finally, keep an eye on the software updates. Outdated programming can hinder capabilities. In fact, over 50% of machine inefficiencies stem from software issues. Staying current can reduce downtime and improve reliability. Taking these steps ensures your CNC milling machine operates at peak efficiency.

10 Essential Tips for Using a CNC Milling Machine Effectively

| Tip No. | Tip Description | Importance | Frequency |

|---|---|---|---|

| 1 | Regularly clean the machine components. | Prevents dust accumulation that can affect performance. | Daily |

| 2 | Calibrate machine settings before use. | Ensures accurate cuts and measurements. | Before each job |

| 3 | Use proper tooling and accessories. | Reduces wear and improves surface finish. | As needed |

| 4 | Inspect cutting tools for wear and damage. | Maintains machining quality and productivity. | Weekly |

| 5 | Keep the software updated. | Improves performance and adds new functionalities. | Monthly |

| 6 | Monitor coolant levels and quality. | Ensures effective cooling and reduces tool wear. | Daily |

| 7 | Follow a structured maintenance schedule. | Extends the lifespan of the machine. | Quarterly |

| 8 | Train operators to use the machine safely. | Reduces accidents and product damage. | As needed |

| 9 | Document all maintenance activities. | Helps track machine performance over time. | Continuous |

| 10 | Evaluate and improve machining processes. | Increases efficiency and reduces costs. | Annually |

Optimizing Tool Selection for CNC Milling Efficiency

When it comes to CNC milling efficiency, tool selection plays a crucial role. According to a report by the American Machinists Association, optimizing tooling can improve machining time by up to 30%. The right tool reduces wear and enhances precision. Always consider factors like material hardness and geometry when selecting a tool.

Tip: Use high-speed steel (HSS) for softer materials. Carbide tools are ideal for harder alloys. This knowledge can significantly impact production costs and output quality. Don’t forget to account for tool life. Extended tool life means less frequent replacements, leading to reduced downtime.

However, many operators overlook tool offsets. This oversight can lead to inconsistencies and increased scrap rates. Reviewing your settings regularly is essential. Tip: Always check for tool wear during operations. Small adjustments can prevent larger, costly mistakes. Engaging in thorough tool analysis helps in better decision-making and can help overcome common machining challenges.

Tool Selection Impact on CNC Milling Efficiency

Effective Programming Techniques for CNC Milling Success

Effective programming techniques are crucial for CNC milling success. Start with a clear design. Use CAD software to create precise models. Ensure the design includes all necessary dimensions and tolerances. This clarity helps avoid mistakes during programming. Errors in the initial design can lead to wasted materials and time. Pay attention to details, even small ones.

When programming, select the right tools and speeds for the job. It's not always straightforward. Test different settings to find what works best. A tool that is perfect for one material may not be suitable for another. Monitor the milling process closely. Listen for strange sounds or vibrations; they can indicate a problem. Make adjustments as needed.

Don’t overlook post-processing steps. Finishing touches can significantly enhance the final product. Sometimes, imperfections show up after milling. Refining these details takes time but is essential. Reflect on your processes regularly. What worked well? What didn’t? Continuous improvement is key to mastering CNC milling programming. Remember, it’s a learning journey, not a destination.

Related Posts

-

Top 10 Benefits of Using a CNC Mill in Your Projects?

-

Top 5 CNC Milling Machines of 2025: Unmatched Precision and Performance

-

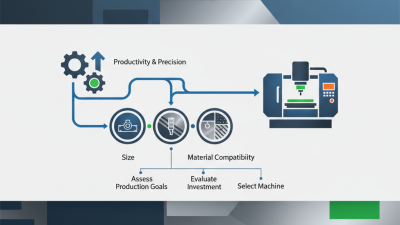

How to Choose the Right CNC Milling Machine for Your Projects

-

2025 Top CNC Parts Trends You Need to Know for Precision Engineering

-

Unlocking Precision: How Metal Laser Cutters Transform Modern Manufacturing

-

Why is CNC Manufacturing Essential for Modern Industries?