The Future of Sheet Metal in 2025 Trends Innovations and Best Practices

As we navigate through the dynamic landscape of modern manufacturing, the significance of sheet metal continues to expand, shaping industries across the globe. By 2025, advancements in technology and innovative practices are set to revolutionize the sheet metal sector, enhancing efficiency, precision, and sustainability. From automation in fabrication processes to the integration of smart technologies, the future of sheet metal is on the brink of a remarkable transformation. This evolution not only promises to optimize production capabilities but also to address the increasing demand for environmentally friendly practices within the industry.

In this era of rapid technological advancement, staying abreast of emerging trends and innovations is crucial for businesses operating within the sheet metal domain. As new materials and techniques become available, manufacturers will need to adapt and embrace a forward-thinking approach to remain competitive. This includes implementing best practices that leverage cutting-edge methods while sustaining quality and customization. By anticipating these changes, stakeholders can position themselves effectively to harness the potential of sheet metal in 2025 and beyond, ensuring they meet the challenges and opportunities of tomorrow's market.

Emerging Trends in Sheet Metal Manufacturing for 2025

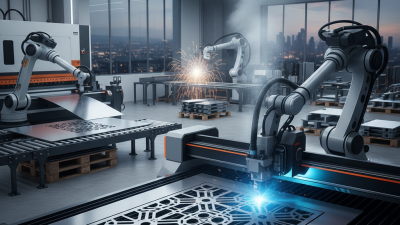

As the sheet metal manufacturing industry evolves towards 2025, several emerging trends are set to shape its future. One significant trend is the increasing integration of advanced automation technologies, including robotics and artificial intelligence. These tools enhance efficiency by reducing manual labor, improving precision, and minimizing error rates in manufacturing processes. As companies adopt smart factories with interconnected machinery, they benefit from real-time data analysis, leading to more informed decision-making and enhanced productivity.

Another critical trend is the growing emphasis on sustainability and eco-friendly practices. Manufacturers are exploring the use of recyclable materials and energy-efficient processes to minimize their environmental footprint. Innovations in material science, such as the development of lightweight, durable alloys and eco-conscious coatings, are also on the rise. These advancements not only respond to regulatory pressures but also cater to a market that increasingly values sustainable practices. As sheet metal manufacturers prioritize green solutions, they will strengthen their competitive edge while contributing positively to the environment.

Additionally, the personalization of products is becoming more prevalent, with manufacturers offering customized solutions to meet specific consumer needs. This shift necessitates flexible manufacturing systems that can quickly adapt to new designs and specifications. By leveraging computer-aided design (CAD) software and flexible production techniques, businesses can cater to growing demands for bespoke products, allowing them to stand out in a competitive landscape.

Innovative Materials Transforming the Sheet Metal Industry

The sheet metal industry is on the cusp of significant transformation, primarily driven by innovative materials that enhance performance, durability, and sustainability. As reported by the Global Sheet Metal Market Research, the demand for advanced materials, such as high-strength aluminum and lightweight composites, is projected to grow by 5.4% annually through 2025. These materials not only reduce manufacturing costs but also allow for greater design flexibility, which is crucial in sectors such as automotive and aerospace.

One notable trend is the rise of eco-friendly materials. With increasing regulations on emissions and waste, manufacturers are exploring options like recycled metals and bio-based alloys. A survey conducted by the Sheet Metal Industries Association indicates that 77% of industry leaders are investing in sustainable practices, aiming to reduce their carbon footprint while meeting consumer demand for greener products. This shift not only aligns with environmental goals but also opens new market opportunities, as consumers increasingly favor companies that prioritize sustainability.

Tip: To stay competitive, businesses should invest in research and development of innovative materials that cater to current market needs. Regularly assess emerging trends and customer preferences to ensure that your product offerings remain relevant and appealing.

Tip: Collaboration with material scientists can lead to breakthroughs in creating composite materials that combine the best properties of different substances. This can result in lighter, stronger, and more versatile products that meet the evolving demands of various industries.

Advanced Technologies Shaping Sheet Metal Fabrication Processes

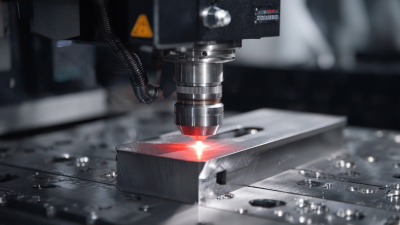

The landscape of sheet metal fabrication is being transformed by advanced technologies that are streamlining processes and enhancing precision. Innovations such as laser cutting and automated robotic welding are at the forefront, enabling manufacturers to achieve intricate designs with minimal material waste. These technologies not only improve efficiency but also elevate the quality of final products, offering the flexibility to accommodate custom orders and rapid prototyping in ways that were previously unattainable.

Additionally, the integration of Industry 4.0 principles into sheet metal fabrication processes is set to revolutionize the sector. Sensors and IoT devices are facilitating real-time monitoring and data analytics, allowing manufacturers to optimize workflows and predict maintenance needs before they lead to downtime. Furthermore, the implementation of advanced software for design and simulation is empowering engineers to innovate more rapidly, resulting in smarter, more sustainable designs. As these trends evolve, the future of sheet metal fabrication will see an increased emphasis on adaptability and efficiency, positioning the industry for significant growth in the years to come.

The Future of Sheet Metal in 2025: Trends Innovations and Best Practices

| Trend/Innovation | Description | Impact | Best Practice |

|---|---|---|---|

| Automation and Robotics | Integration of automated systems and robotic arms to enhance precision and efficiency in sheet metal fabrication. | Increased production rates and reduced labor costs. | Invest in training for operators and regular maintenance of equipment. |

| 3D Printing | Utilization of additive manufacturing for creating complex sheet metal parts. | Enables customization and rapid prototyping. | Combine traditional methods with 3D printing for optimal results. |

| Sustainability Practices | Implementation of eco-friendly materials and recycling processes. | Reduction of waste and environmental impact. | Establish a waste management program to improve recycling rates. |

| IoT Integration | Deployment of Internet of Things devices for real-time monitoring and management of fabrication processes. | Enhanced efficiency and predictive maintenance capabilities. | Regularly analyze data to optimize machine performance. |

| Digital Twins | Creating virtual replicas of physical assets for simulation and analysis. | Facilitates better decision-making and process optimization. | Integrate with software solutions for continuous improvements. |

Sustainable Practices in Sheet Metal Production for the Future

The future of sheet metal production is increasingly focused on sustainability, with innovative practices and technologies paving the way for a greener industry. In 2025, manufacturers are expected to prioritize eco-friendly materials, utilizing recycled metals and advanced alloys that minimize environmental impact. This shift not only reduces waste but also lowers the carbon footprint associated with extraction and processing. Implementing energy-efficient machinery and renewable energy sources in production lines will further enhance sustainability, creating a more responsible approach to manufacturing.

Additionally, the adoption of digital technologies such as automation and AI will revolutionize how sheet metal is produced. Smart factories will harness data analytics to optimize processes, minimize material waste, and improve energy consumption. The integration of these technologies allows for precise customization and faster production times, meeting the demands of a rapidly evolving market while adhering to sustainable practices. By embracing these innovations, the sheet metal industry can contribute significantly to environmental sustainability while maintaining high standards of efficiency and quality.

Best Practices for Adapting to Market Changes in Sheet Metal Sector

In the rapidly evolving sheet metal sector, adaptability is crucial for businesses to stay competitive. Market trends indicate a significant shift towards more sustainable

manufacturing practices, with a report by MarketsandMarkets projecting that the global green metal market will reach approximately $1 trillion by 2025.

This shift not only influences material selection but also production techniques, making it essential for companies to invest in eco-friendly technologies and processes.

Implementing lean manufacturing principles can also reduce waste and enhance efficiency, allowing businesses to respond swiftly to changing market demands without compromising quality.

Moreover, embracing innovations such as automation and smart manufacturing will be critical for the future of the sheet metal industry. A study from McKinsey & Company suggests that businesses leveraging Industry 4.0 technologies could increase productivity by up to 23% by 2025. To thrive, companies must provide continuous training to their workforce, ensuring that employees are equipped with the necessary skills to operate new technologies effectively. Furthermore, maintaining flexible supply chains will allow manufacturers to quickly adapt to fluctuations in demand while minimizing disruptions. By integrating these best practices, the sheet metal industry can better navigate the challenges and opportunities that lie ahead.

Related Posts

-

Top 10 Best Sheet Metal Fabrication Techniques for Your Industry Needs

-

How to Achieve Precision with Aluminum Machining Techniques

-

Discover the Future of Precision with Laser Metal Cutting Machines in Modern Manufacturing

-

Top 10 Advantages of Using Laser CNC for Precision Cutting and Engraving

-

Understanding the Advantages of CNC Laser Cutters in Modern Manufacturing Processes

-

Revolutionizing Industries with Precision Aluminum Machining Techniques and Their Impact on Production Efficiency