How to Improve Aluminum Machining Efficiency and Accuracy?

Aluminum machining plays a critical role in various industries, contributing significantly to the production process. According to a report by the Institute for Advanced Manufacturing, aluminum parts are used in over 80% of aerospace applications. The demand for precision machining continues to rise. However, many manufacturers struggle with optimizing their machining efficiency.

Machining aluminum can be challenging due to its unique properties. Aluminum is soft, which leads to rapid wear on cutting tools. Reports indicate that tool wear can increase cycle times by up to 30%. Additionally, poor machining practices can result in a 20% increase in scrap rates. These figures highlight the need for improved strategies in aluminum machining processes.

To enhance efficiency and accuracy, manufacturers must focus on selecting appropriate machining parameters. Adjustments in cutting speed, feed rate, and tooling can lead to significant improvements. However, a lack of thorough analysis may lead to missed opportunities for optimization. Industry experts recommend regular evaluation of machining techniques to ensure competitiveness. Understanding these factors is essential for advancing aluminum machining capabilities.

Techniques for Selecting the Right Aluminum Alloy for Machining

Selecting the right aluminum alloy is crucial for machining efficiency and accuracy. Different alloys offer distinct properties, affecting their machinability. For example, 6061 is known for its good mechanical properties and weldability, making it a popular choice. However, this alloy can create challenges like tool wear in intensive machining processes.

On the other hand, choosing 7075 can enhance strength but may be more difficult to machine. It requires specific tools and techniques to achieve precision without compromising the integrity of the material. Understanding these differences is essential. It's often tempting to stick to familiar alloys, but experimenting with others can yield better results.

Moreover, thickness and shape also matter. Thicker materials may lead to longer machining times, while complex shapes can complicate the process. Assessing the intended use of the final product is key. Sometimes, it’s easy to overlook these factors in the rush to complete a project. Reflecting on material choices can lead to improved outcomes and more efficient processes in the long run.

How to Improve Aluminum Machining Efficiency and Accuracy? - Techniques for Selecting the Right Aluminum Alloy for Machining

| Aluminum Alloy | Characteristic | Machining Efficiency (Rating: 1-10) | Typical Applications |

|---|---|---|---|

| 6061 | Good weldability and corrosion resistance | 8 | Structural components, automotive parts |

| 7075 | High strength, low weight | 7 | Aerospace, military applications |

| 2024 | Very high strength, good toughness | 6 | Aircraft structures, automotive components |

| 5052 | Excellent corrosion resistance | 8 | Marine environments, automotive fuel tanks |

| 3003 | Good workability, moderate strength | 5 | Cooking utensils, chemical equipment |

Optimizing Cutting Tool Geometry for Enhanced Aluminum Machining

When machining aluminum, optimizing cutting tool geometry can significantly boost efficiency and accuracy. The tool's shape affects how it interacts with the material. A well-designed cutting edge minimizes friction, preventing heat buildup during the process. However, achieving the perfect geometry is challenging. Different grades of aluminum require different cutting angles. Not all setups yield the best results on every job.

A sharp cutting tool often leads to cleaner cuts. Yet, a tool that is too sharp can quickly wear down. Finding the right balance is crucial. For example, a slightly rounded edge can enhance durability without sacrificing precision. Still, operators must regularly assess tool performance. Sometimes, changes in aluminum composition may alter the best practices for tool design.

Another aspect to consider is rake angle. A positive rake angle can reduce cutting forces, improving surface finish. However, this can also lead to chatter, impacting precision. Some may find themselves compromising between aggressive cutting and maintaining part accuracy. Regular feedback from the machining process can help adjust the geometry over time. Fine-tuning these elements demands attention, but it pays off when done correctly.

Adjusting Machining Parameters to Improve Efficiency and Accuracy

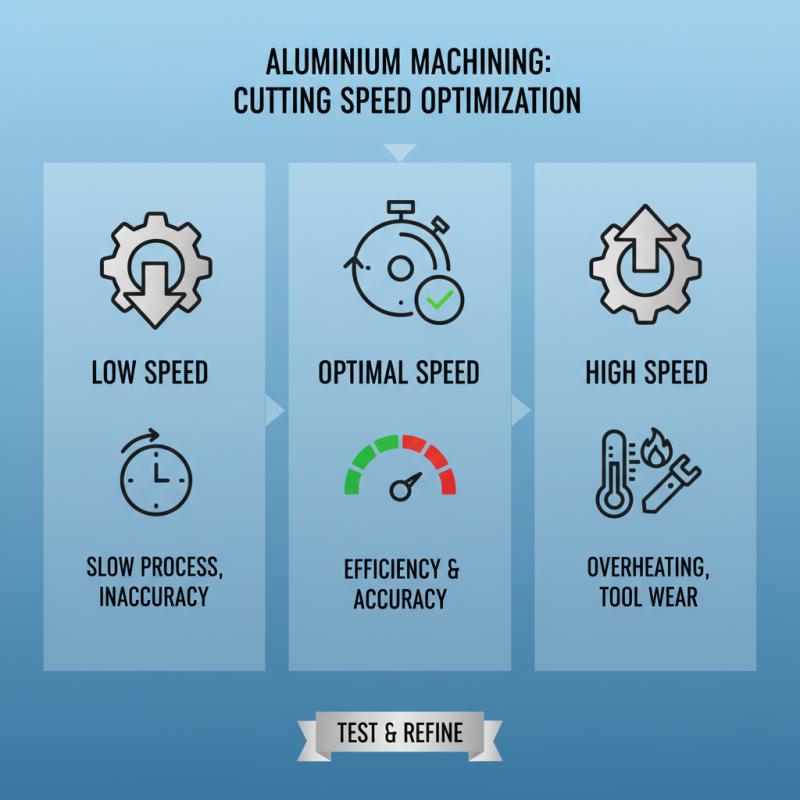

Adjusting machining parameters is crucial for enhancing the efficiency and accuracy of aluminum machining. Start with the cutting speed. A speed that is too high can lead to overheating and tool wear, while too low will slow down the process. Finding the sweet spot requires testing. Experiment with different speeds to see which yields the best results.

Next, consider the feed rate. A higher feed rate might increase productivity but can compromise the surface finish. It often leads to unwanted vibrations. On the other hand, a slow feed rate can be inefficient. Regularly reviewing and adjusting the feed rate helps to balance both quality and speed.

Finally, tool selection and cooling methods also play a significant role. Using sharp, high-quality tools makes a difference. But even the best tools can fail without proper cooling. Inconsistent coolant delivery can lead to overheating, affecting accuracy. Regularly check coolant flow and concentration. These adjustments require ongoing evaluation and may expose flaws in the original setup, but the results can significantly enhance machining performance.

Implementing Advanced Coolant Strategies for Aluminum Machining

Implementing advanced coolant strategies is crucial for enhancing aluminum machining efficiency and accuracy. Coolants play a vital role in reducing tool wear and thermal distortion during machining. Using the right coolant can significantly improve surface finish and dimensional accuracy. However, not all coolant methods yield the same results. Some strategies may even lead to poor performance if not applied correctly.

One effective approach is using high-pressure coolant systems. These systems direct coolant precisely at the cutting zone. This helps to dissipate heat and flush away chips. The challenge lies in selecting the right pressure and flow rates. If they are set too low, the benefits diminish. Conversely, excessive pressure can cause adverse effects, like tool breakage. Finding a balanced approach requires trial and error.

Another method includes using biodegradable and eco-friendly coolants. They are becoming popular due to environmental concerns. However, these coolants often require different handling and application techniques. Mismanagement can lead to increased costs and longer cleanup times. It’s essential to train operators on the new processes to avoid costly mistakes. Continuous evaluation and adjustments will ensure optimal results in the long run.

Utilizing CNC Technology for Precision in Aluminum Machining

CNC technology has revolutionized aluminum machining, significantly improving precision. With computer numerical control, machines can be programmed to execute intricate designs. This technology ensures consistent results, even with complex specifications. Features like real-time feedback allow for immediate adjustments, promoting accuracy.

However, operators must be well-trained. Missteps in programming can lead to waste or inaccurate parts. Understanding the material's properties is crucial. Aluminum can behave differently under varying speeds or temperatures. When not accounted for, issues can arise, leading to production delays.

Routine maintenance of CNC machines cannot be overlooked. A clean and calibrated machine enhances both efficiency and accuracy. It's easy to forget about machine upkeep in a busy shop. Yet, neglecting this can lead to precision loss and increased costs. Reflection on these aspects can drive improvements in the production process.

Related Posts

-

Unlocking Precision: The Future of Aluminum Machining in Modern Manufacturing

-

Revolutionizing Industries with Precision Aluminum Machining Techniques and Their Impact on Production Efficiency

-

What is Aluminum Machining and How Does it Benefit Your Industry

-

How to Achieve Precision with Aluminum Machining Techniques

-

Best Laser Cut Aluminum Tips for Precision Projects and Cost Savings

-

How to Effectively Use Laser Cut Aluminum in Your Projects Guide 2025