Best Laser Cut Aluminum Tips for Precision Projects and Cost Savings

In the realm of precision manufacturing, "laser cut aluminum" has emerged as a game-changer. Renowned expert in metal fabrication, Dr. Evelyn Carter, emphasizes the significance of this innovative technique by stating, "Utilizing laser cut aluminum not only enhances accuracy but also optimizes material costs for complex projects." This evolution in cutting technology allows designers and engineers to achieve intricate designs with unmatched precision, making it a preferred choice for diverse industries.

As the demand for high-quality components continues to rise, understanding the best practices in working with laser cut aluminum becomes essential. Whether you're embarking on a small DIY project or managing large-scale production, knowing the nuances of this method can yield significant cost savings and superior outcomes. Embracing these tips can ensure that your precision projects not only meet but exceed expectations, ultimately leading to greater customer satisfaction and enhanced operational efficiency.

With laser cutting technology advancing rapidly, now is the ideal time to explore how laser cut aluminum can transform your manufacturing processes, ensuring that you stay ahead in this competitive landscape. By leveraging these insights, professionals can harness the full potential of laser cut aluminum, paving the way for innovation and excellence in their projects.

Best Practices for Choosing the Right Laser Cut Aluminum Thickness

When working with laser cut aluminum, selecting the right thickness is crucial for achieving precision and optimizing cost-effectiveness. The thickness of the aluminum affects the material's strength, weight, and the type of applications suitable for various projects. Typically, thinner materials are advantageous for intricate designs and detailed engravings, allowing for fine cuts without excessive power usage. For projects requiring durability or structural integrity, opting for thicker materials is advisable, as they provide stability and can withstand handling and environmental stresses.

Understanding the specific requirements of your project can guide your choice of aluminum thickness. For decorative items or prototypes, a thickness ranging from 1mm to 3mm often suffices, enabling detailed designs while keeping costs low. In contrast, industrial applications may benefit from thicknesses of 4mm or greater, ensuring robustness and safety. Additionally, consider the capabilities of your laser cutting machine, as different machines have varying tolerances and power settings, which can influence the quality of the cut depending on the thickness selected. By aligning your project needs with the right aluminum thickness, you can maximize both precision and cost savings efficiently.

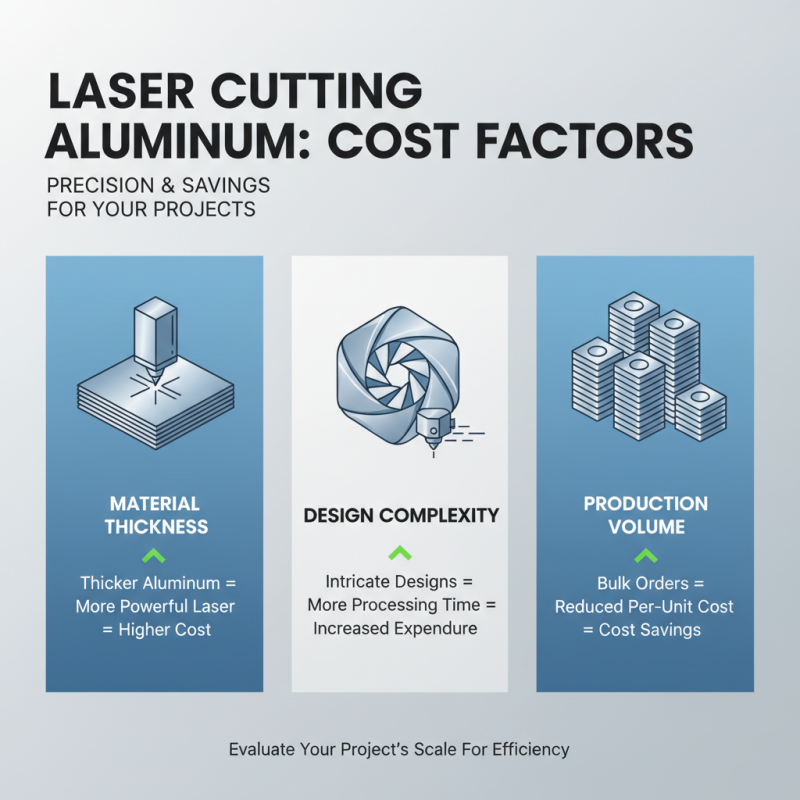

Understanding the Cost Factors in Laser Cutting Aluminum Components

When considering laser cutting aluminum components, understanding the cost factors involved is crucial for precision projects and overall cost savings. The primary elements that influence the expense include material thickness, complexity of design, and production volume. Thicker aluminum requires more powerful lasers, which typically leads to higher costs. Similarly, intricate designs demand more processing time, thus increasing the overall expenditure. Lastly, bulk orders often result in reduced per-unit costs, making it essential to evaluate your project's scale.

For effective cost management, here are a few tips: First, simplify your design where possible. Reducing the number of intricate cuts not only saves on processing time but can also prevent excessive material waste, lowering costs. Second, consider using nesting software to optimize material usage. By strategically arranging parts on the aluminum sheet, you can maximize the amount of usable material, thus minimizing waste and expense. Lastly, work closely with your fabricator to finalize specifications before production begins. Clear communication regarding your needs can help avoid costly misunderstandings and adjustments during the cutting process.

Techniques to Ensure Precision in Laser Cutting Aluminum Projects

When undertaking aluminum projects that require precision, mastering specific techniques in laser cutting can significantly enhance the outcome. One fundamental aspect is ensuring the proper settings on the laser cutter. This includes selecting the right power, speed, and frequency parameters tailored to the thickness and type of aluminum being used. Utilizing a slower cutting speed can improve the cut quality by providing the laser more time to effectively melt the metal, which is critical for achieving clean edges and precise details.

Another vital technique is the use of appropriate assist gases during the cutting process. Introducing oxygen or nitrogen can influence cut quality and kerf width. While oxygen can provide faster cutting speeds, it may lead to oxidization on the cuts, necessitating post-processing work. Conversely, using nitrogen minimizes oxidation and provides a cleaner finish but at a slight increase in cutting time. Experimenting with these gas types can lead to optimized costs and better precision, making them essential considerations for anyone looking to produce intricate aluminum designs efficiently.

Best Laser Cut Aluminum Tips for Precision Projects and Cost Savings

| Technique | Description | Cost Savings (%) | Precision Level |

|---|---|---|---|

| Machine Calibration | Regularly calibrate laser cutters to ensure accurate cuts. | 15% | High |

| Material Thickness Optimization | Choose the right thickness for aluminum to minimize waste. | 20% | Medium |

| Optimal Cutting Speed | Adjusting speed settings for different materials to enhance precision. | 10% | High |

| Use of Assist Gases | Incorporate assist gases to improve cut quality and reduce slag. | 18% | Very High |

| Post-Processing Techniques | Finishing processes to achieve better aesthetics and precision. | 12% | Medium |

Analyzing the Benefits of Laser Cutting over Traditional Aluminum Fabrication

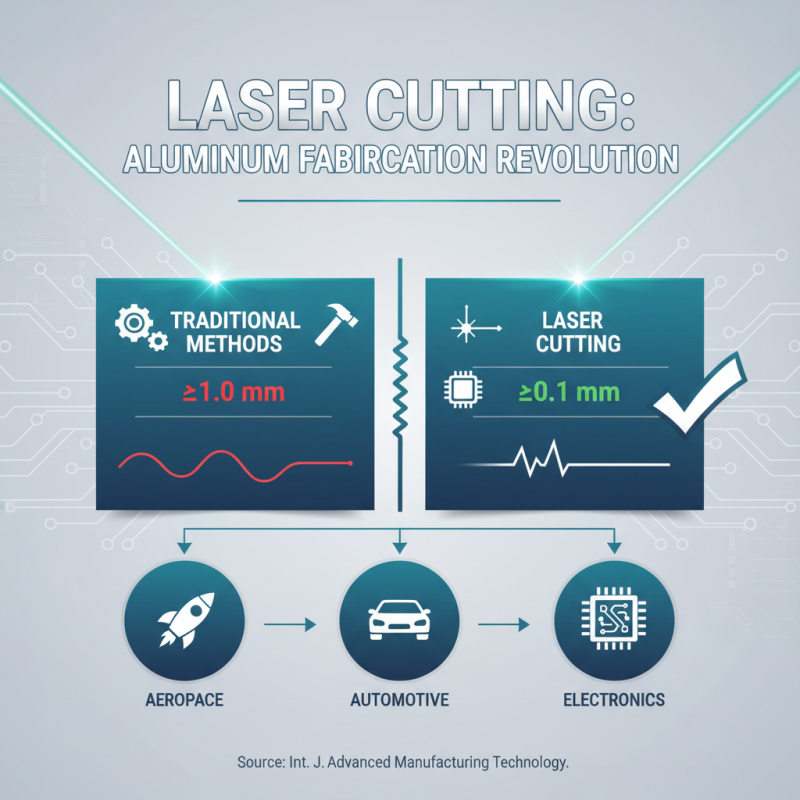

Laser cutting has revolutionized the aluminum fabrication industry, offering superior precision and efficiency compared to traditional methods. According to a report from the International Journal of Advanced Manufacturing Technology, laser cutting can achieve tolerances as tight as ±0.1 mm, significantly enhancing the accuracy of components. This precision allows for intricate designs that would be challenging to replicate with conventional machining techniques, making it ideal for complex projects in sectors such as aerospace, automotive, and electronics.

Additionally, the cost-effectiveness of laser cutting is noteworthy. A study by the Manufacturing Institute reveals that businesses utilizing laser cutting technology can reduce material waste by up to 30% due to the ability to nest parts optimally on the aluminum sheets. Traditional methods often lead to greater waste as they rely on more extensive setup times and greater scrap levels. Moreover, the speed of laser cutting means shorter lead times and increased productivity, allowing companies to respond swiftly to market demands and customer needs. With the combined benefits of high precision and cost savings, laser cutting has positioned itself as a preferred choice for modern aluminum fabrication.

Common Mistakes to Avoid in Laser Cutting Aluminum for Precision Work

When engaging in precision laser cutting of aluminum, avoiding common pitfalls is crucial for achieving high-quality results and cost efficiency. One prevalent mistake is neglecting the importance of proper material preparation. According to a report from the International Laser Cutting Association, uneven surfaces or contaminants on the aluminum can lead to poor cutting quality, resulting in increased material wastage and production costs. For optimal outcomes, ensuring that the aluminum sheets are clean, flat, and free of debris can significantly enhance the precision of the cuts.

Another common error is failing to select the appropriate laser settings for the specific thickness and alloy of aluminum being cut. Research indicates that using incorrect power levels or speeds can cause issues such as excessive heat distortion or incomplete cuts. A study published in the Journal of Manufacturing Science showed that precise adjustments in pulse duration and cutting speed can reduce kerf width by up to 20%, which greatly influences the overall finish and fit of the components being produced. By carefully calibrating the laser parameters to match the unique properties of aluminum, manufacturers can achieve both superior precision and notable cost savings.

Laser Cutting Aluminum: Key Metrics

This bar chart displays key metrics involved in laser cutting aluminum for precision projects. It highlights important parameters such as power, speed, thickness, material cost, and processing time, which can influence both the quality of work and cost efficiency.

Related Posts

-

How to Achieve Precision with Aluminum Machining Techniques

-

Unlocking Precision: The Future of Aluminum Machining in Modern Manufacturing

-

What is Aluminum Machining and How Does it Benefit Your Industry

-

Ultimate Guide to Choosing the Right Laser Metal Cutting Machine for Your Business Needs

-

Unlocking Market Opportunities for Aluminum Sheet Metal at the 138th Canton Fair 2025

-

Unlocking the Advantages of Laser Machine Technology for Modern Manufacturing