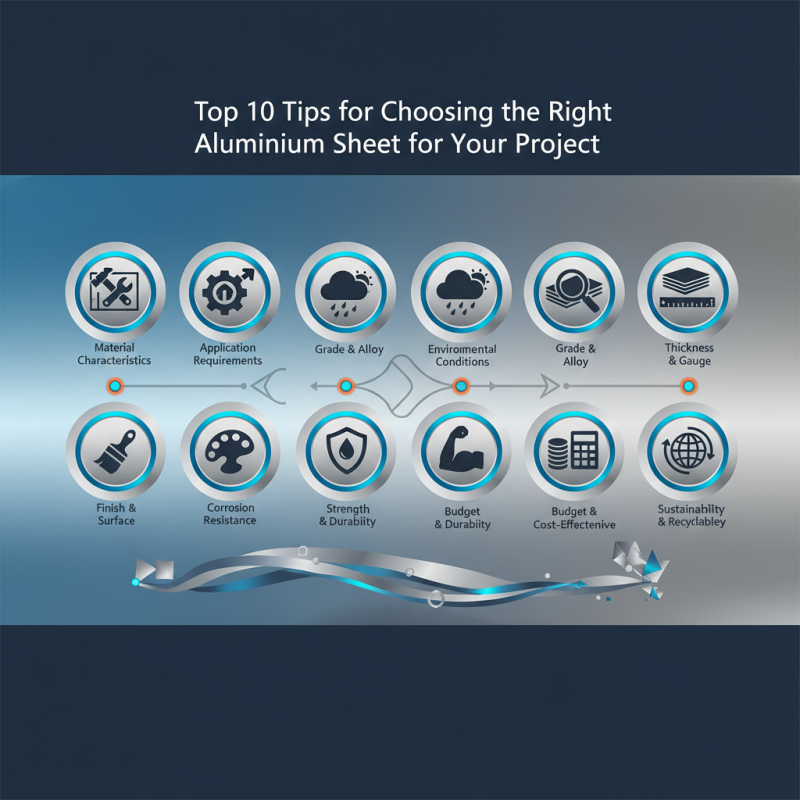

Top 10 Tips for Choosing the Right Aluminium Sheet for Your Project

When embarking on a project that requires the use of aluminium sheets, making the right choice can be pivotal to the success and durability of the final product. As industry expert Dr. Emily Thompson aptly states, "The choice of aluminium sheet can significantly impact both the aesthetic and functional qualities of your project." With various grades, thicknesses, and finishes available, navigating through the options may seem overwhelming. However, understanding the specific needs of your project can simplify the selection process.

Aluminium sheets are utilized across a multitude of industries, from construction to automotive, thanks to their lightweight and corrosion-resistant properties. Choosing the right aluminium sheet not only ensures optimal performance but also enhances the overall appeal of your project. By considering key factors such as material characteristics, application requirements, and environmental conditions, project managers and designers can make informed decisions that align with their objectives. This guide presents the top ten tips for selecting the perfect aluminium sheet tailored to your specific needs, enabling you to achieve excellent results.

Understanding the Different Types of Aluminium Sheets Available

When selecting the right aluminium sheet for your project, it's crucial to understand the various types available on the market. Aluminium sheets can be categorized based on their alloy composition, thickness, and surface finish, each tailored to suit specific applications. Common variants include 1050, 3003, and 5052 alloys, each offering different levels of strength, corrosion resistance, and workability. For instance, 1050 is known for its excellent corrosion resistance and formability, making it ideal for chemical and food processing industries, while the 5052 alloy is favored in marine applications due to its superb resistance to saltwater.

Another significant factor is the thickness of the aluminium sheet, which can range from a few millimeters to several centimeters. Thicker sheets tend to provide more structural strength, making them suitable for heavy-duty applications, while thinner sheets are often utilized for decorative purposes or lightweight projects. Additionally, the surface finish can also affect the aesthetic and functional quality of the sheet. Options include mill finish, anodized, and painted, each providing different levels of durability and visual appeal, allowing you to choose based on the environmental conditions and design needs of your project. Understanding these distinctions is key to making an informed decision that aligns with your specific requirements.

Assessing the Thickness and Weight Requirements for Your Project

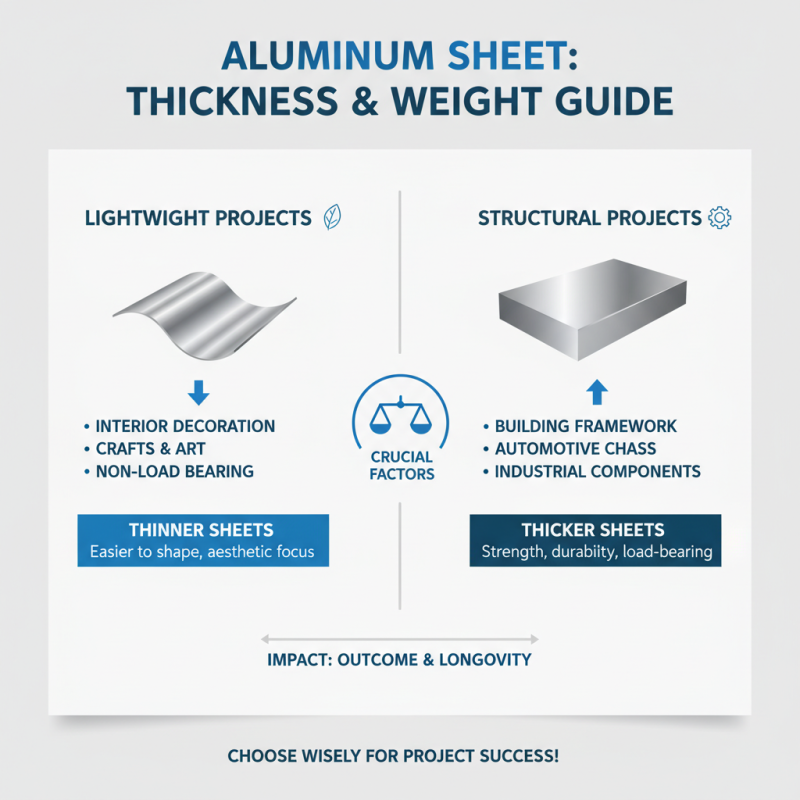

When selecting the right aluminium sheet for your project, thickness and weight are crucial factors that can significantly impact the outcome. Different applications require different thicknesses; for example, a lightweight project like an interior decoration may only need a thinner sheet, while structural applications necessitate a heavier gauge for added strength and durability. It’s essential to assess not only what you need for your immediate project but also how the thickness will affect the structural integrity and performance over time.

In addition to evaluating the thickness, understanding the weight requirements is vital. Heavier sheets provide more substantial support but can also increase the difficulty of handling and installation. Consider the tools and equipment you have available, as well as the safety implications of lifting and maneuvering heavier materials. Ensuring that the dimensions align with your project requirements can prevent unnecessary challenges later.

One tip is to refer to standard thickness measurements commonly used in your industry. This can provide a baseline for what is typically deemed suitable, allowing you to make informed decisions. Additionally, always account for the weight distribution over the support structures involved in your project. By carefully balancing thickness and weight, you can achieve both the aesthetic and functional goals of your project effectively.

Evaluating the Coating and Finish Options for Aluminium Sheets

When choosing aluminium sheets for your project, evaluating the coating and finish options is crucial for both aesthetics and performance. According to a recent industry report by the Aluminium Association, around 60% of aluminium sheet applications involve various finishing processes that significantly enhance durability and visual appeal. Popular coatings like anodizing and powder coating not only improve corrosion resistance but also provide decorative options that can align with the overall design of your project.

Tip: Always assess the intended use of the aluminium sheet to select an appropriate finish. For outdoor applications, opt for finishes that offer higher weather resistance, such as fluoropolymer coatings, which have been shown to withstand harsh conditions without fading.

Additionally, it's essential to consider the thickness and type of coating. A report from the International Aluminium Institute highlights that sheets coated with a thicker layer often exhibit superior performance in terms of scratch and impact resistance. Therefore, investing in a well-coating strategy can lead to a longer lifecycle for your products while reducing maintenance costs in the long run.

Tip: Consult technical specifications before finalizing the coating type, as some finishes may require specific processing methods and have limitations based on the sheet's alloy composition. By making informed decisions based on these factors, you can ensure the right balance between functionality and aesthetics for your aluminium sheets.

Considering the Cost and Budget Constraints for Your Aluminium Choice

When selecting the right aluminium sheet for a project, it's imperative to consider the cost in relation to your budget constraints. Aluminium sheets come in various grades and thicknesses, which can significantly affect their price. Assessing your project's specific requirements and understanding how different materials may contribute to overall costs is essential.

For example, while a higher-grade aluminium may be more expensive upfront, its durability and performance might save money in the long run through reduced maintenance and replacement costs.

Moreover, other factors such as processing, transportation, and installation should also be taken into account when budgeting. The cost of additional treatments, coatings, or custom sizes can add up quickly and may not be immediately apparent. Creating a comprehensive budget that includes all these potential expenses ensures that the aluminium choice aligns with your financial capabilities while meeting the necessary project specifications. Balancing quality with affordability will ultimately lead to a more successful and sustainable project outcome.

Consulting with Experts for Tailored Recommendations and Guidance

When embarking on a project that requires the use of aluminium sheets, consulting with experts can prove invaluable. Professionals possess a wealth of knowledge about various grades, thicknesses, and finishes that may suit specific applications. Their tailored recommendations can help you avoid common pitfalls and ensure that you select the ideal aluminium sheet for your needs. Engaging in discussions with industry specialists can also provide insight into the latest innovations and trends, enabling you to make informed decisions.

Additionally, when you seek expert guidance, it's essential to convey your project's requirements clearly. Consider the intended use, environmental factors, and any aesthetic considerations you may have. Experts often suggest beginning with the basics, such as understanding the differences between alloyed and non-alloyed aluminium. These factors can directly influence the sheet’s durability and performance in your unique application.

Another crucial aspect is to pay attention to the manufacturing process of the aluminium sheets you are considering. Professionals can help explain how fabrication techniques affect the material's properties. This knowledge will allow you to make choices that align with your project’s objectives, ensuring that you choose the right aluminium sheet to achieve optimal results.

Related Posts

-

10 Essential Tips for Optimizing Your CNC Metal Cutting Process

-

Exploring CO2 Laser Cutter Innovations at the 138th Canton Fair 2025 in China

-

Common Issues Faced in CNC Cutting Operations

-

Solutions for Efficient Laser Cut Aluminum Manufacturing in a Competitive Global Market

-

5 Best Metal Laser Cutter Techniques for Precision Cutting

-

Unlocking Precision: How CNC Metal Cutting Transforms Modern Manufacturing Techniques