Top Tips for Choosing a Fiber Laser Cutter for Your Needs?

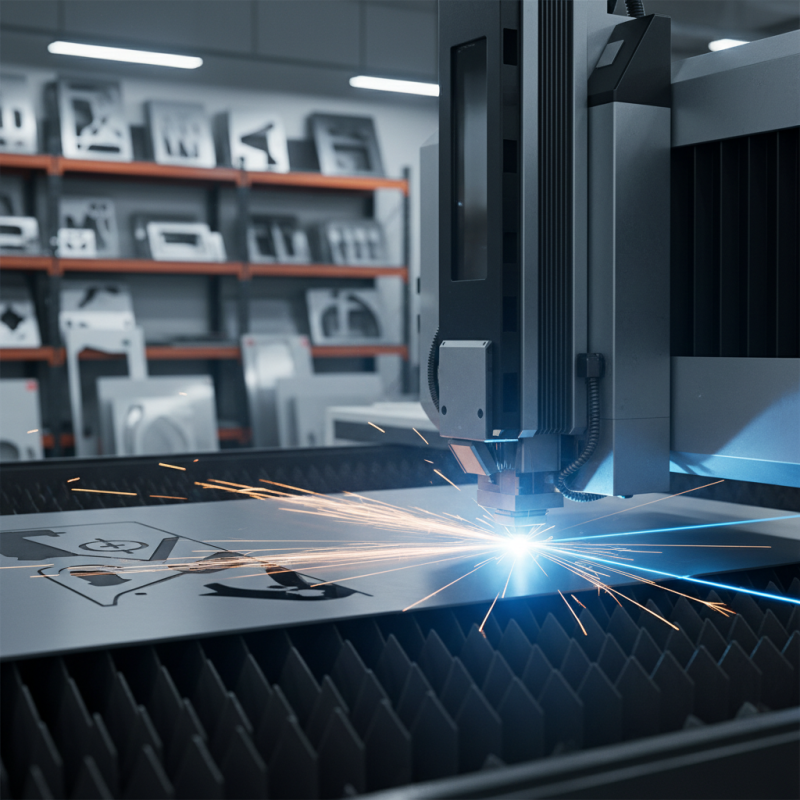

Choosing the right fiber laser cutter can significantly impact your production capabilities. With various options available, understanding your specific needs is essential. A fiber laser cutter offers precision and efficiency, making it popular among manufacturers.

Consider the materials you plan to work with. Some cutters excel with metals, while others may handle non-metals better. Assess the thickness and type of material. This can guide your decision toward a cutter with the right power and speed.

It's also important to weigh your budget. High-end models come with advanced features but can be expensive. Finding a balance between quality and cost is key. Ensure you research brands and user reviews to identify what fits your requirements best. Reflect on your long-term goals, as choosing wisely now can save you time and money later.

Understanding the Basics of Fiber Laser Cutters

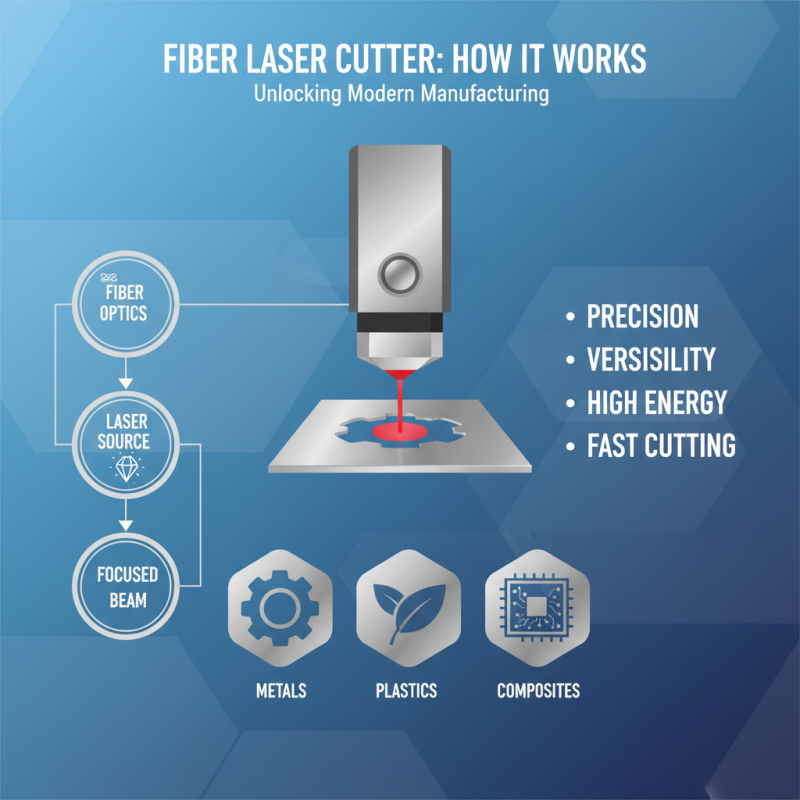

Fiber laser cutters are popular due to their precision and versatility. Understanding how they work is essential. At their core, these machines use a focused laser beam to cut materials. This cutting process relies on the high energy produced by the laser. It can easily slice through metals, plastics, and more.

The wavelength of fiber lasers allows for better absorption by metals, which makes them highly effective. Maintenance is relatively low, but the initial setup can be complex. Users often struggle to master the software that drives these machines. Learning curves can be steep. Mistakes can happen during the first few runs, especially for newcomers.

Choosing the right fiber laser cutter involves understanding your specific needs. Consider the types of materials you will be cutting. The thickness and hardness of materials also matter. If you focus too much on price, you may overlook features that improve cutting quality. Additionally, you might find that the speed of cutting varies. This could impact productivity significantly. Reflecting on these aspects will lead to better decision-making.

Key Factors to Consider When Selecting a Fiber Laser Cutter

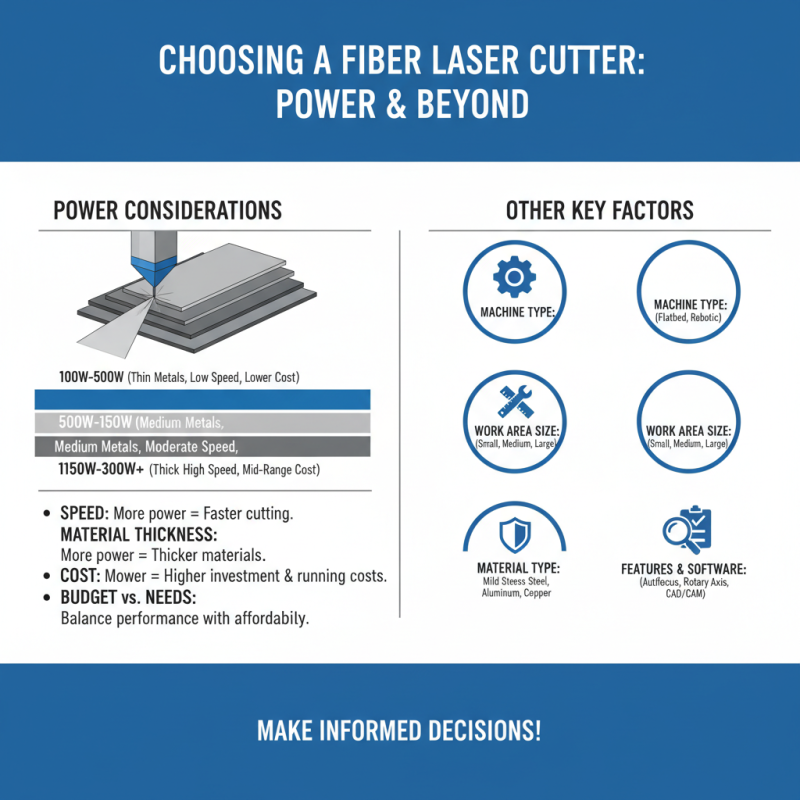

Choosing the right fiber laser cutter can be challenging. Many factors come into play. One critical aspect is power. Most fiber laser cutters range from 100W to 3000W. Higher power means faster cutting speeds and the ability to work with thicker materials. However, more power also leads to higher costs. Buyers must balance their budget against their cutting needs.

Another important factor is the material you intend to cut. Fiber lasers work well with metals like steel, aluminum, and brass. According to a recent industry report, around 70% of fabricators prefer fiber laser technology for metal cutting. Yet, if your applications include non-metals, ensure the cutter can handle those materials. Versatility can be a double-edged sword; advanced machines might not be necessary for simpler jobs.

Working space is another consideration. A larger machine requires more room but may be essential for bigger projects. This aspect is often overlooked, leading to workflow inefficiencies. Also, consider the software compatibility. Some systems lack user-friendly interfaces. Investing time to understand these factors is crucial for maximizing your investment, though it can be complex.

Comparing Different Fiber Laser Cutter Brands and Models

When exploring different fiber laser cutter brands and models, it’s essential to look at key features. The power of the laser is critical. Higher wattage often leads to faster cutting speeds. However, excessive power may not be necessary for thin materials. Balance is key. The cutting area also matters; larger sizes can handle bigger projects but may take up more space.

Next, consider the ease of use. Some models come with advanced software. This can simplify the design process and improve workflow efficiency. Yet, if the software is complicated, it might lead to frustration. Look for user-friendly interfaces. Additionally, maintenance is a factor often overlooked. Some cutters require regular upkeep, while others are more self-sufficient.

Finally, price can vary widely. High-end models may promise superior performance, but they might not always deliver significant benefits for your needs. Weighing costs against features is necessary. Set a budget, but remain flexible depending on your project requirements. Remember, the best choice isn't just about specifications; it also reflects how well it fits your operations and goals.

Evaluating Your Specific Cutting Needs and Applications

When choosing a fiber laser cutter, it's essential to assess your specific cutting needs and applications. Different industries require various cutting capabilities. For example, the metal fabrication sector often seeks equipment that can handle thick materials, while electronics manufacturers focus on precision cutting. According to a recent industry report, fiber laser cutters account for over 35% of the global laser systems market. This statistic demonstrates the growing reliance on fiber laser technology across diverse sectors.

Tip: Evaluate the thickness of materials you'll be cutting. Most fiber lasers work efficiently on metals, but their performance varies with material thickness. For instance, a machine ideal for 10 mm material might struggle with 20 mm. Knowing your requirements helps avoid costly mistakes.

Tip: Consider the speed and precision requirements of your applications. The report indicates that fiber lasers typically offer 2-10 times faster cutting speeds than traditional CO2 lasers. However, if accuracy is compromised at high speeds, it could lead to wasted resources. The balance between speed and quality is crucial.

As you explore options, factor in your production volume. Investing in a high-capacity model may not be necessary for low-volume operations. Overestimating your needs can lead to overspending on machinery you won't fully utilize. Think carefully about your current and future projects.

Comparison of Fiber Laser Cutter Features

Maintenance and Support for Your Fiber Laser Cutter Choice

When selecting a fiber laser cutter, maintenance and support are critical factors. Regular upkeep ensures the machine operates at peak efficiency. According to a recent industry report, poorly maintained lasers can lose up to 20% of their cutting efficiency within the first year. This can lead to increased costs and downtime.

Choosing a provider with reliable support is also essential. The quality of service can vary widely among manufacturers. Some may offer only basic troubleshooting, while others provide comprehensive training and remote assistance. A survey indicated that 62% of businesses prefer suppliers with a solid reputation for customer support. This often translates into faster problem resolution and less disruption in production.

Consider the availability of spare parts and technical support in your region. Maintenance can turn into a hassle if parts are hard to find, prolonging downtimes. Opting for a cutter with readily available parts may prevent future headaches. Reflecting on these factors aids in making an informed decision. The goal is to minimize interruptions and maximize productivity in your operations.

Top Tips for Choosing a Fiber Laser Cutter for Your Needs

| Feature | Considerations | Maintenance | Support |

|---|---|---|---|

| Laser Power | Choose based on material thickness and type | Regular cleaning of lenses and mirrors | Access to technical support for issues |

| Cutting Speed | Evaluate speed based on production needs | Check for software updates regularly | Training services offered by the supplier |

| Cooling System | Consider air or water cooling based on usage | Monitor coolant levels and quality | Availability of replacement parts |

| Software Compatibility | Ensure compatibility with design software | Keep software updated for optimal performance | User manuals and online resources |

| Warranty | Check warranty duration and coverage | Regular check-ups recommended for warranty | Customer service responsiveness |

Related Posts

-

How to Choose the Best Laser Cutter for Your Projects?

-

Exploring CO2 Laser Cutter Innovations at the 138th Canton Fair 2025 in China

-

How to Choose the Right Laser Cutter for Your Business Needs

-

How to Choose the Best Fiber Laser Cutter for Your Needs

-

7 Amazing Benefits of Using Laser Metal Cutting Machines for Precision Work

-

How to Choose the Best Laser Cutter for Your DIY Projects in 2023