Top 5 CO2 Laser Cutters for Precision and Quality?

The demand for precision cutting in various industries continues to rise. One of the best tools for this task is the CO2 laser cutter. These machines deliver high-quality cuts on a range of materials. From wood to acrylic and metal, they are versatile. For professionals and hobbyists alike, finding the right CO2 laser cutter is essential.

Selecting the top CO2 laser cutters is not straightforward. Each model offers unique features and capabilities. Users often face challenges when determining which machine suits their needs best. Price, power, and cutting speed matter. But so do the support and warranty options. These factors can significantly impact the user experience.

In this article, we will explore the top 5 CO2 laser cutters known for precision and quality. We'll break down their advantages and potential drawbacks. It’s crucial to examine these factors to make an informed decision. A good choice can enhance your projects and workflow. However, the wrong choice may lead to frustration. Let's delve into these machines and understand their offerings.

Top Features to Consider in CO2 Laser Cutters

When selecting a CO2 laser cutter, precision and quality are paramount. First, consider the laser power. Higher power can cut thicker materials. A machine with 40W to 100W is often suitable for varied tasks. However, more power may lead to deep burns on certain materials. It's crucial to match power levels with the intended material.

The cutting speed also plays a role. Faster machines can save time, but they might sacrifice detail. A balance between speed and quality is vital. Look for machines with adjustable speed settings. This feature allows for greater control on intricate designs.

Moreover, the bed size is important. A larger bed offers versatility and can accommodate big projects. However, larger machines can be cumbersome to operate. User-friendly interfaces enhance control, but what if they are not intuitive? Always check for reviews before making a purchase. Each feature can significantly impact your work, making careful consideration essential.

Comparison of Precision Levels in CO2 Laser Cutting Machines

In the realm of CO2 laser cutting machines, precision is key. The ability to create intricate designs relies on accuracy. According to a recent industry report, precision levels vary significantly among machines. Some systems achieve an impressive tolerance level of ±0.1 mm, while others may fall short, around ±0.5 mm. This disparity impacts the final product quality.

Tips: Always check the specifications for precision. It’s crucial to align your needs with what a machine can deliver. An underspecified machine can lead to frustrating results, especially in detailed projects.

Another important factor is beam quality. A better beam results in cleaner cuts and finer details. Systems that utilize high-quality optics can enhance performance, reducing the need for post-processing. Some reports indicate that machines with a higher beam quality can cut through materials up to three times faster than others, reducing overall production time.

Tips: Evaluate your material types and thicknesses before choosing a machine. Know how these factors influence your project requirements. Not all machines excel in cutting all materials equally, which is a vital consideration.

Top 5 CO2 Laser Cutters for Precision and Quality

This bar chart compares the precision levels of five top CO2 laser cutters, measured in millimeters (mm). Lower values indicate higher precision, making it easier to choose the most suitable machine based on cutting requirements.

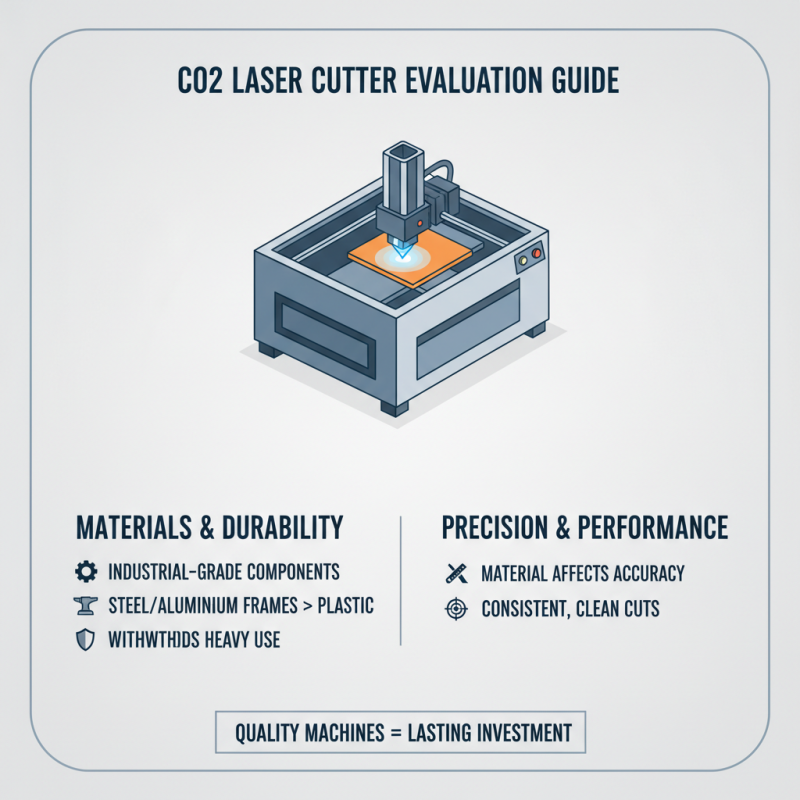

Quality Assessment: Materials and Durability of CO2 Laser Cutters

When evaluating CO2 laser cutters, materials and durability are crucial. High-quality machines often utilize industrial-grade components. These parts see heavy use and need to withstand consistent wear and tear. Reports suggest that machines made from steel or aluminum tend to last longer than those with plastic housing. Precision is key; materials can directly affect the accuracy of cuts.

User experience in the field shows varying durability. While some devices perform excellently for years, others may struggle under regular use. It's noted that frequent maintenance helps but can be overlooked. A study found that proper upkeep can extend machine lifespan by up to 40%. Still, many users report frustration with the maintenance requirements. This calls for a balance between quality and user commitment.

Additionally, adaptability to different materials is essential for functionality. A versatile laser cutter should work well with wood, acrylic, and metal. However, not all machines meet this criterion effectively. Inconsistent results with specific materials can create problems. A well-rounded approach in choosing a CO2 laser cutter is vital, but it's clear that durability still needs attention.

User Reviews and Insights on the Best CO2 Laser Cutters

When it comes to CO2 laser cutters, user insights reveal significant trends in precision and quality. High precision is crucial for industries such as electronics and manufacturing. Many users report that a machine's cutting accuracy can vary greatly. Some user reviews highlight that slight misalignments can cause major errors in final products.

A study by the Laser Institute of America noted that CO2 laser cutters can achieve cutting tolerances within 0.1 mm. Yet, some users find it challenging to maintain this level of consistency. Factors like material type and thickness can influence outcomes. A user experienced issues when switching from wood to acrylic, noting differing results.

Maintenance also plays a key role in performance. Users often mention that regular lens cleaning is vital for optimal cutting quality. Neglecting this can lead to reduced precision. Feedback indicates that understanding the machine’s capabilities is essential. A user once shared that despite their machine's capabilities, it took several trials to master the settings for specific materials. This journey of learning is a common theme across many user reviews.

Top 5 CO2 Laser Cutters for Precision and Quality

| Model | Cutting Area (mm) | Max Cutting Speed (mm/s) | Laser Power (W) | User Rating |

|---|---|---|---|---|

| LaserPro X1 | 600 x 400 | 300 | 60 | 4.8/5 |

| Fusion Pro 48 | 1219 x 610 | 500 | 120 | 4.7/5 |

| Epilog Zing 16 | 406 x 610 | 360 | 40 | 4.6/5 |

| Thunder Laser Nova | 1000 x 600 | 400 | 80 | 4.5/5 |

| Orion Motor Tech | 500 x 300 | 200 | 40 | 4.2/5 |

Maintenance Tips for Maximizing CO2 Laser Cutter Performance

Maintaining a CO2 laser cutter is crucial for optimal performance. Regular cleaning is essential. Dust and debris can accumulate on lenses and mirrors, affecting beam quality. A simple cotton swab and lens cleaner can do wonders. Keep a routine schedule for this task. It’s easy to forget, but neglecting it can lead to costly mistakes.

Check your machine's alignment regularly. A misaligned beam can result in uneven cuts. It may take time to set it correctly, but patience pays off. Every so often, it’s wise to double-check settings before embarking on precision projects. Calibration can be tedious, but skipping this step can ruin the final product.

Watch for signs of wear in critical components. Belts and bearings may need attention. They might seem fine at first glance, but may not perform under stress. Listening for unusual noises can guide you. Don't ignore them. Small issues may lead to larger failures down the line. Regular maintenance saves time and enhances the overall quality of your work.

Related Posts

-

How to Choose the Best CO2 Laser Cutter for Your Projects and Needs

-

Exploring CO2 Laser Cutter Innovations at the 138th Canton Fair 2025 in China

-

How to Choose the Right CO2 Laser Cutter for Your Business Needs

-

Top Tips for Choosing a Fiber Laser Cutter for Your Needs?

-

Understanding the Advantages of CNC Laser Cutters in Modern Manufacturing Processes

-

Unlocking Precision: The Ultimate Guide to 2025's Top CNC Laser Cutters and Their Applications