Top 2025 Tube Laser Technologies: Innovations and Applications You Need to Know

The advent of tube laser technology has revolutionized various industries by enhancing precision, efficiency, and versatility in manufacturing processes. As we look towards 2025, it is imperative to explore the cutting-edge innovations and practical applications that tube lasers bring to the table. This advanced technology has paved the way for transformed design capabilities and has opened new avenues for customization in metal fabrication, automotive, aerospace, and more.

In this era of rapid advancements, staying informed about the latest tube laser technologies becomes crucial for manufacturers seeking to maintain a competitive edge. From improved processing speeds to intricate cutting abilities, the tube laser is set to redefine how materials are handled and manipulated. This article delves into key innovations in tube laser technology and highlights their potential applications, equipping readers with the knowledge needed to leverage these advancements effectively. The future of fabrication lies in harnessing the power of tube laser technology, and understanding its role will be vital for businesses aiming for growth and innovation in the years to come.

Innovative Advancements in Tube Laser Technology for 2025

The advancements in tube laser technology for 2025 are set to revolutionize various industries, enhancing both productivity and precision. The integration of artificial intelligence in laser cutting systems is one of the most notable innovations. AI algorithms can optimize cutting paths and adjust parameters in real-time, which significantly reduces material waste and improves the overall efficiency of the manufacturing process. This technology allows operators to create complex geometries with unparalleled accuracy while minimizing cycle times.

Furthermore, the adoption of advanced materials for laser components is facilitating higher performance levels in tube laser systems. For instance, the use of fiber lasers continues to dominate the market due to their efficiency and ability to cut through thicker materials with ease. Additionally, improvements in cooling systems have enabled these lasers to operate at elevated power levels without compromising reliability. These innovations not only expand the capabilities of tube lasers but also contribute to cost savings and enhanced operational sustainability, making them essential tools in modern manufacturing.

Top 2025 Tube Laser Technologies: Innovations and Applications You Need to Know

The bar chart above illustrates the key performance metrics for tube laser technologies expected in 2025. The improvements in cutting speed, precision, material versatility, energy efficiency, and user-friendly features reflect the innovative advancements in this field.

Key Applications of Tube Laser Technologies in Various Industries

Tube laser technologies have accelerated advancements across various industries, enabling precise cutting, welding, and fabrication processes that enhance production efficiency and quality. One key application is in the automotive sector, where tube lasers are utilized for cutting complex shapes in structural components. This not only reduces material waste but also streamlines the assembly process, leading to faster production times and improved vehicle performance. The ability to produce intricate designs with tight tolerances allows manufacturers to innovate in both aesthetics and functionality.

Another significant area of application is in the construction industry, where tube laser technologies facilitate the manufacturing of lightweight yet robust structural frameworks. These lasers provide the precision needed to create components that meet the rigorous demands of modern architecture while minimizing labor costs and reducing fabrication times. Additionally, in the furniture industry, tube lasers enable the creation of stylish designs that might be too complex or costly using traditional methods, allowing for greater creativity and customization in pieces of furniture. This versatility across sectors highlights the transformative impact of tube laser technologies on contemporary manufacturing processes.

Comparative Analysis of Leading Tube Laser Technologies in 2025

In 2025, the landscape of tube laser technologies has evolved significantly, showcasing innovations that enhance efficiency and precision in metal fabrication. A comparative analysis reveals that advancements in fiber laser systems are leading the charge, offering superior beam quality and faster cutting speeds compared to traditional CO2 lasers. These fiber lasers utilize advanced coolant systems and improved optics, reducing downtime and increasing throughput in high-volume production environments.

Moreover, the integration of automation and artificial intelligence into tube laser systems has transformed their applications. As predictive analytics become commonplace, manufacturers can optimize cutting paths and minimize waste, significantly lowering production costs. The latest models feature user-friendly interfaces that allow for real-time adjustments and monitoring, facilitating a seamless operational flow. Additionally, innovations in multi-axis capabilities empower users to perform complex cuts and intricate patterns that were once labor-intensive, driving creativity in design and applications across various industries.

Top 2025 Tube Laser Technologies: Innovations and Applications You Need to Know

| Technology Type | Key Innovations | Application Areas | Efficiency (%) | Cost (USD) |

|---|---|---|---|---|

| Fiber Laser | High Precision Cutting | Automotive, Aerospace | 95% | $150,000 |

| CO2 Laser | Thicker Material Cutting | Metal Fabrication, Signage | 85% | $100,000 |

| Solid-State Laser | Compact Design | Electronics, Medical Devices | 90% | $120,000 |

| Ultrafast Laser | Pulsed Operation | Micro-Machining, Textiles | 99% | $180,000 |

Future Trends in Tube Laser Technologies and Their Implications

The landscape of tube laser technologies is evolving rapidly, driven by significant advancements in automation, precision, and efficiency. As businesses increasingly turn to laser systems for their fabrication needs, the global tube laser market is projected to reach approximately $4.6 billion by 2025, according to a recent market analysis report. This growth is fueled by developments such as fiber laser sources, which offer enhanced capabilities in cutting speed and energy efficiency compared to traditional CO2 lasers. Fiber lasers are also more versatile, allowing for a wider range of materials to be processed with high-quality finishes.

Future trends indicate a significant shift towards incorporating artificial intelligence (AI) and machine learning into tube laser applications. These technologies can optimize cutting paths, reduce material waste, and streamline production schedules. Research shows that integrating AI can improve operational efficiency by up to 30%, making a compelling case for manufacturers to adopt these innovations. Furthermore, the rise of Industry 4.0 has set the stage for smart factories, where interconnected laser systems will enable real-time monitoring and predictive maintenance, ultimately leading to reduced downtime and increased productivity in tube fabrication processes. As these advancements take hold, industries ranging from automotive to aerospace will continue to benefit from enhanced customization and rapid prototyping capabilities, underscoring the transformative impact of tube laser technologies in modern manufacturing.

Impact of Tube Laser Innovations on Manufacturing Efficiency and Precision

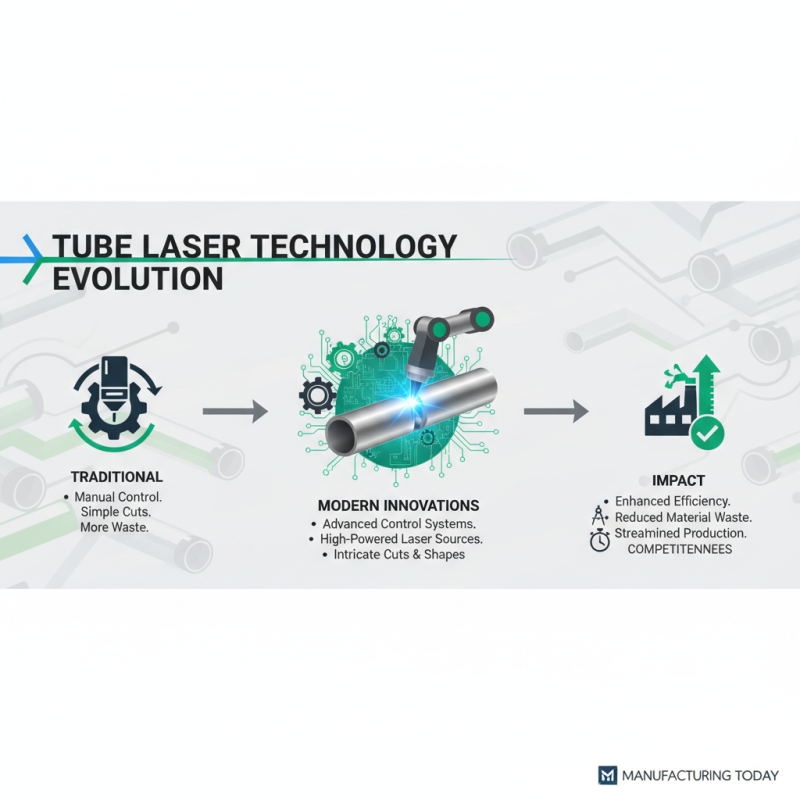

The evolution of tube laser technologies has significantly enhanced manufacturing efficiency and precision, making it an essential focus for industries aiming to stay competitive. With innovations such as advanced control systems and high-powered laser sources, manufacturers can achieve intricate cuts and shapes that were previously unattainable. This precision not only reduces material wastage but also minimizes the need for secondary operations, thereby streamlining production workflows.

Tips: Investing in training and familiarization with these cutting-edge technologies can greatly enhance operational efficiency. Encourage your team to stay updated on system features and best practices to maximize the return on investment in tube laser technology.

Moreover, the ability to customize tube laser equipment for specific applications helps in catering to diverse manufacturing demands. This adaptability means that industries ranging from automotive to aerospace can utilize tube lasers to meet their unique challenges. The integration of automation further amplifies productivity, allowing for consistent output quality and reduced downtime.

Tips: Regular maintenance of your tube laser systems ensures longevity and sustained performance. Scheduling periodic check-ups and software updates will keep your equipment operating efficiently and reduce the risk of costly breakdowns.

Related Posts

-

How to Choose the Right Laser Cutter for Your Business Needs

-

Common Issues Faced in CNC Cutting Operations

-

Exploring CO2 Laser Cutter Innovations at the 138th Canton Fair 2025 in China

-

10 Essential Tips for Mastering Laser CNC Technology

-

What is Aluminum Machining and How Does it Benefit Your Industry

-

Best Laser Cut Aluminum Tips for Precision Projects and Cost Savings